www.industryemea.com

02

'22

Written on Modified on

Resolving the global semiconductor shortage

Semiconductor chips store data on almost every modern digital device that we use. According to ASML, in 2020, more than one trillion chips were produced around the world. Despite their use in many of the products we rely on, the manufacturing process is complex and requires precision.

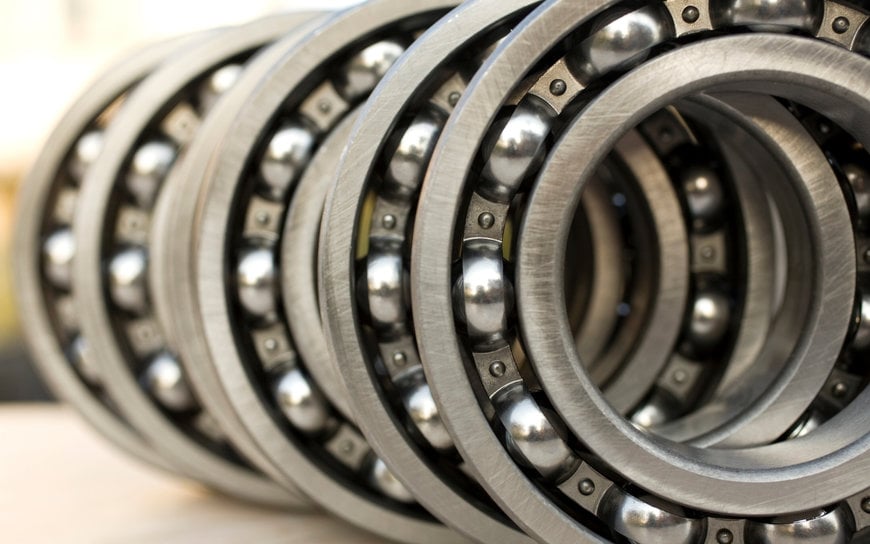

According to Deloitte, we can expect the global shortage of semiconductor chips to continue as supply catches up with rising demand. Manufacturing these chips requires highly controlled manufacturing conditions where noise, vibration and dust are kept to a minimum. Here, Chris Johnson, managing director at specialist bearings supplier SMB Bearings, explains the crucial part that bearings play in the manufacturing of semiconductor chips.

Manufacturing any chip involves multiple processes. First, silicon wafers are sliced and polished before being covered with a light-sensitive “photoresist” coating. The chip wafer is then inserted into a lithography machine where it’s exposed to deep ultraviolet (DUV) or extreme ultraviolet (EUV). The necessary patterns are then etched in the wafer. Bearings can be found in various semiconductor processing equipment, and their configurations will facilitate the specific process involved.

Cleanroom environments

To accomplish this process, manufacturers must operate in delicate working conditions in the form of cleanrooms. The environment must be enclosed, with airborne particles, room temperature, air pressure, noise and lighting all tightly controlled. The site will often be compliant with ISO 14644-1 Class 5 or lower, which specifies a minimum allowed particle count of 3,520 particles 0.5µm or smaller.

A single wafer can go through as many as 200 steps before it reaches industry standard, which means the production site must be completely sterile and free of particulates. This means installing powerful cleanroom heating, ventilation and air condition (HVAC) and filtration systems to purify and circulate the air to remove any particles up to the allowed limits.

Avoiding outgassing

Airborne molecular contamination (AMC) is a concern in precision manufacturing. The release of vapour from equipment materials in cleanrooms is the most significant contamination source for volatile organic compounds (VOC), which can negatively impact production tools and increase costs.

Maintaining steady semiconductor production means constantly monitoring AMC levels. The choice of bearing material and lubricant can help to avoid complications by minimising outgassing potential. We recommend using stainless steel for vacuum or cleanroom applications because it exhibits low outgassing. Plastic bearings made from PEEK and full ceramic silicone nitride alternatives may also be considered but the choice will depend on the application.

If we turn to lubricants, most greases can often vaporise. Those working in semiconductor manufacturing environments should select low-volatility, perfluorinated greases with low outgassing rates. If the machinery is operating at low speeds, using no lubricant, or opting for a “dry” lubricant like molybdenum disulphide is also an option.

Reducing vibration

The processes used to achieve clean air needed means investing in pumping, pipes, ducts and fan systems — all of which generate unwanted vibration unless sufficiently isolated. Vibrations both in and outside a cleanroom can severely impact the final product.

High quality bearings are essential to minimise excess noise and vibration. Damaged balls or raceways, poor roundness and inadequate lubrication all create noise that can impede semiconductor production. Therefore, regularly monitoring surface finish and the roundness of the balls and bearing rings is a must.

As with outgassing, the choice of lubrication is also critical for controlling vibration. We suggest using finely filtered low noise greases since these contain fewer, smaller solid particles that generate noise when they pass between the balls and raceway. If bearings are inadequately lubricated, or filled with the incorrect grease, manufacturers should contact a supplier like SMB Bearings, who can offer relubrication services to prevent outgassing and disruptive noise.

The global shortage of semiconductor chips may be destined to continue, but making small changes can help manufacturers to prevent machine downtime and unplanned rework. Selecting low noise bearings and applying the necessary lubrication can help to avoid disturbing equipment, limit outgassing and maintain a steady semiconductor production at a time when the industry desperately needs resilience.

www.smbbearings.com