www.industryemea.com

08

'22

Written on Modified on

FPT INDUSTRIAL RIDES THE NEW WAVE OF HYBRIDIZATION AT CANNES YACHTING FESTIVAL 2022

FPT Industrial deployed a full fleet of innovations, champions and award-winning products from its Marine Range at the Cannes Yachting Festival 2022, held in Cannes (France) from 6 to 11 September 2022.

At its booth (Jetée 183, Vieux Port), FPT Industrial indeed revealed the next step in its marine hybridization route, one of the key results of its collaboration with Vulkan Hybrid Architect, and also showed off the Guinness World Speed Record holding diesel powerboat engine, the C16 1000, and the double design award-winning Red Horizon Integrated Marine Control System. The exhibits were rounded off with a wide range of advanced services dedicated to customers, including telematics and remote assistance.

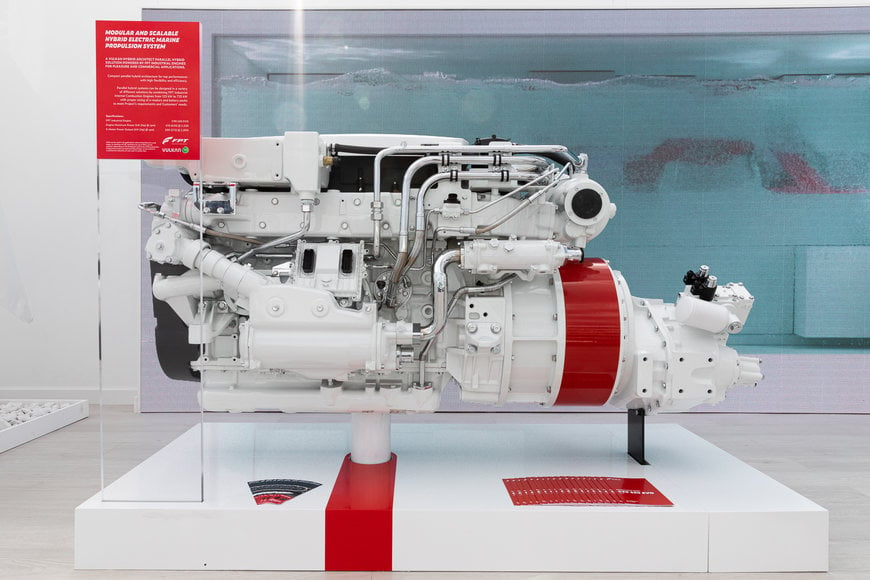

NEW MODULAR AND SCALABLE PARALLEL HYBRID ELECTRIC MARINE PROPULSION SYSTEM – THE FPT INDUSTRIAL AND VULKAN HYBRID ARCHITECT COLLABORATION SETS SAIL

Despite no changes being expected in sector emission regulations for the next few years, the broad sustainability trend is becoming more and more relevant in the marine sector, too. The accelerating pace of installed marine hybrid applications, and the experience gained over the last decade by systems integrators is shaping different technological solutions, suitable for specific mission profiles.

Taking into account this ever-growing trend, FPT Industrial has decided to create its own parallel hybrid electric marine propulsion system by teaming up with Vulkan Hybrid Architect, a division of the Vulkan Group, a leading high-tech drivetrain and vibration control technology supplier, active in the Marine, Industry & Energy, Refrigeration & A/C sectors. Vulkan Hybrid Architect is a highly skilled systems integrator, capable of developing tailor-made solutions for shipyards and owners: FPT Industrial has chosen Vulkan to carry out the engineering and deliver a turnkey integrated hybrid-drive propulsion system package.

Compact Parallel Hybrid is the most promising architecture option for both commercial and pleasure vessels in the 100 to 1,000 hp market, since it is able to deliver top performance along with high levels of flexibility and efficiency. The Parallel Hybrid systems can, indeed, be offered in a wide variety of different solutions by combining FPT Industrial diesel engines from 125kW to 735kW with proper sizing of e-motors and battery packs to meet any project requirements and customer needs.

Designed to offer reduced maintenance requirements and costs, fuel savings, emissions reductions and exceptional comfort, as well as allowing access to marine protected areas in full electric drive mode, the FPT Industrial – Vulcan Hybrid Architect solution unveiled in Cannes features a FPT Industrial C9 650 EVO diesel engine, a Hybrid Clutch to engage and disengage the ICE, an E-machine in the form of a synchronous permanent magnet and axial flux motor, a frequency converter, a marine gearbox, a mechanical interface, and a vibro-acoustic isolation system.

There are four main modes available. The E-Sailing Mode allows maneuvering and sailing at low speed with zero emissions, with the Hybrid Clutch disengaging the diesel engine. In Diesel Mode, the diesel engine is synchronized to the e-motor and then connected to the shaft line with the clutch. The power from the diesel unit can be used by the e-machine to feed the hotel load or to recharge batteries. When docked or anchored, Generator Mode enables the diesel engine to be used at idle (with the gearbox in neutral) to generate power through the E-machine. In Boost Mode, the e-machine is powered by batteries and contributes to driving the shaft line for maximum speed. The entire hybrid system can be easily monitored and managed via user-friendly touchscreen panels.

“To date, we have awarded Vulkan preferred partner status with regard to the design and development of marine hybrid solutions engineered using FPT Industrial marine engines,” said Guglielmo Tummarello, Marine Market Segment Director at FPT Industrial. “Through this collaboration, we will be able to address the growing market demand for these sustainable power units and to provide our customers with complete turnkey solutions, also relying on our strong distributor network.”

“Even the yacht world is moving forward towards decarbonization, with more and more electrification from green sources as well,” noted Gian Piero Repetti, Vulkan Hybrid Architect Project Leader and Global Business Developer in the Yachting sector at Vulkan Group. “The life of a diesel engine might be enough to sustain today’s operations for several years, but this is the time to make a change. Therefore, Vulkan is not only working towards sustainability in its operations, but adding a new focus, offering a new way of onboard living in absolute comfort and with a ’more than just green’ attitude.”

FPT INDUSTRIAL C90 HYBRID DRIVE TRAIN MAIN COMPONENTS

FPT INDUSTRIAL C90 650 EVO

8.7 liter, in-line 6-cylinder Diesel engine

Max Power: 478kW @ 2530 rpm

Hybrid Clutch

The diesel engine is engaged and disengaged by an electromagnetic clutch, managed by a dedicated control unit, placed between the diesel engine and the E-machine

E-machine

Synchronous permanent magnet and axial flux E-machine (200 kW@2000 rpm in only 170 mm of axial length) for an extremely compact and powerful hybrid module. Several E-machine sizes will be available to meet customer requirements.

Mechanical interfaces and vibroacoustic isolation

Two flexible Vulkan couplings, one between the engine flywheel and the hybrid clutch, the other one between the e-machine and the gearbox, ensure the best possible vibroacoustic behavior for the entire system; the couplings and the hybrid clutch are placed into custom designed bell housings, providing stiffness and compactness to the entire hybrid drivetrain.

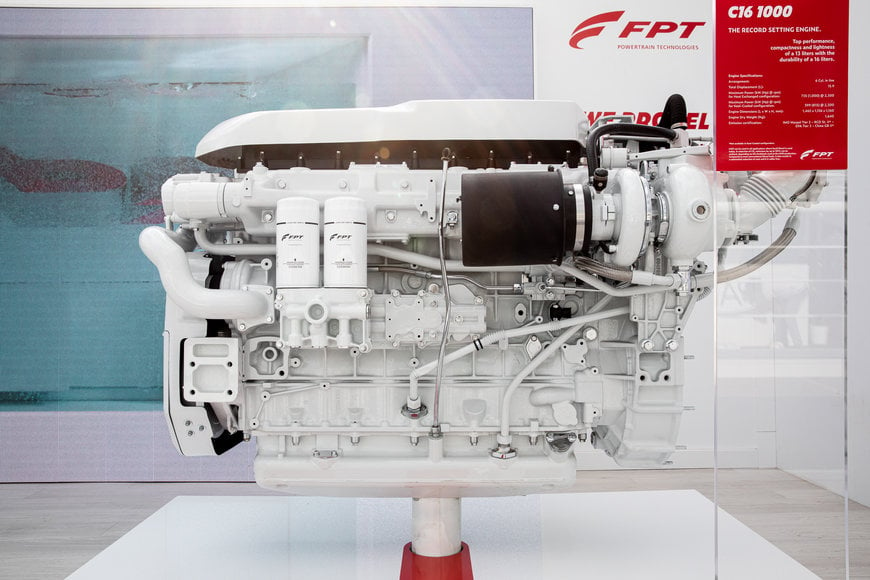

C16 1000 – THE CHAMPION IS BACK

Also available in keel cooling configuration, the C16 1000 offers impressive durability, outstanding power (63 hp/l) and torque (220 Nm/l) density, and light weight in the light commercial segment. Best-in-class maintenance intervals of up to 600 hours translates into easier and cheaper maintenance operations.

The engine is compliant with IMO2, RCDII, EPA3 and China GBII emission regulations, allowing the brand to cover global opportunities, and it is also available in keel cooled configuration. These characteristics, together with the wide range of possible applications, such as motor yachts, long-range cruisers, sports fishing boats, governmental and state bodies, pilot and rescue, light ferries and light commercial fishing vessels, demonstrate the versatility of the C16 1000.

C16 1000 Specifications

Architecture: In-line six cylinder

Injection System: Common Rail (up to 2,200 bar)

Air Handling: Two water-cooled wastegate turbos, single stage + aftercooler

Valves per Cylinder: 4

Displacement: 15.9 l

Bore x Stroke: 141 x 170 mm

Max Rated Power: 1,000 hp @ 2,300 rpm

Max Torque: 3,500 Nm

Dry Weight: 1,690 kg

Dimensions (L/W/H): 1,465 x 1,136 x 1,160 mm

RED HORIZON – HIGH TECHNOLOGY, AWARD-WINNING STYLE

Red Horizon is FPT Industrial’s integration of the most advanced marine technologies in engine, monitoring and control systems. Developed in collaboration with two leading global companies – ZF, a technology supplier of next-generation mobility systems, and Navico (Simrad), a manufacturer of marine electronics – Red Horizon guarantees full navigation control and safety, optimal driving comfort, and easy handling and mooring.

Available in combination with any top engine from FPT Industrial’s Cursor and NEF families, Red Horizon is presented inside a unique environment, inspired by the automotive world, luxury cars and villas, and vintage Italian boats, resulting in a comfortable bridge with a touch of minimalism, where customers can feel at home. This unique style has received two of the world top design awards – Gold Winner of the 2021 edition of the New York Product Design Awards in the Watercraft Category, and the 2021 Good Design Award.

FPT Industrial adopts ZF electronic propulsion controls (SmartCommand) and maneuvering systems (JMS) specifically matched to FPT Industrial engines.

FPT Industrial Premium Controls provides an innovative, compact and user-friendly control head with an impressive experience in terms of comfort and safety through different control modes, while FPT Industrial Premium Joystick delivers simple and intuitive boat control during maneuvers, even in complex docking situations.

Based on Navico-Simrad technology, the MFD (Multi-Function Display) offers more than an engine monitoring visualization, thanks to its potential integration with many other vessel devices (radar, echosounder, cameras, etc.). The integrated system was developed in collaboration with Navico, using customized FPT software, layout and branding.

CUSTOMER SERVICE – STANDING BESIDE THE BRAND’S CUSTOMERS

The Brand’s stand at Cannes 2022 featured a corner fully dedicated to Customer Service, a particularly important area when dealing with marine engines. This corner offered a clear vision of the pillars on which FPT Industrial has built its renowned customer service reputation: reliability, protection and uptime.

The common trait of all these areas is delivering the best customer experience and supporting them in the easiest and most efficient manner, so they can rely on our marine engines and spend more time on the water with minimal worries.