www.industryemea.com

06

'15

Written on Modified on

Highly dynamic at 50 years of age

NORD DRIVESYSTEMS celebrates anniversary at Hannover Messe 2015

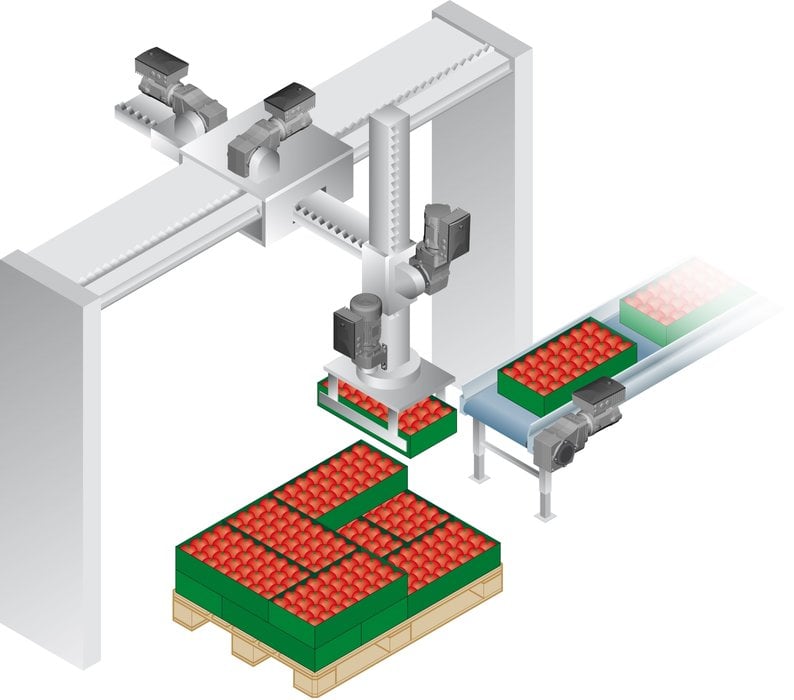

A simulator showcasing dynamic drive performance will be a centerpiece of this year’s NORD DRIVESYSTEMS presentation at the industrial fair in Hanover. Systems consisting of an asynchronous motor, a helical bevel gearbox, and an SK 200E series decentralized frequency inverter demonstrate high precision and superior agility in complex motion sequences. Solutions based on such intelligent drive configurations enable cost-efficient servo-level applications. Integrating a PLC, the inverters demonstrate their support for drive-related functions according to IEC 61131. They are also suited for safety applications and feature sophisticated functions such as synchronization, coordinated multi-axis operation, and flying shear. In a dedicated intra-logistics model, versatile mechatronic drive units will carry out positioning tasks such as contact-free and gap-free accumulation and seamless transfer of transported goods between horizontal conveyors and hoists.

Energy efficiency remains another focus for the drive supplier. In addition to motors of all current and upcoming efficiency classes up to IE4, NORD presents complete configurations suitable for system efficiency certification (“IES”) according to the latest Ecodesign standard EN 50598. Hannover Messe visitors will be able to learn more about the holistic classification of entire “Power Drive Systems” (PDS) based on specific losses at eight load points instead of energy efficiency percentiles. As an additional exhibition highlight, aluminum drives with nsd tupH anti-corrosion treatment will be shown alongside cast-iron units with a conventional paint finish. The nsd tupH treatment gives the housings a smooth and enduring surface. Even scratches and other minor damage to the surface do not impair the systems’ lasting resilience against corrosion.

Illustration 2: The nsd tupH anti-corrosion surface treatment ensures drive systems meet demanding hygiene requirements and endure in harsh environments

The company will also promote large industrial gear units – only NORD manufactures them with a one-piece gear case for torques up to 242,000 Nm. The construction allows for compact designs with high radial and axial load capacities even for heavy-duty units. New large parallel shaft gear units are among the latest additions to a comprehensive portfolio of gears that draws on half a century of expertise: the first NORD gears were assembled exactly 50 years ago in April of 1965, when the company had just been founded and had only three employees. Today, NORD employs well over 3,000 people around the world. While the global headquarters remain in Bargteheide near Hamburg, the full-scale provider of drive technology has long been operating on an international scale. The NORD DRIVESYSTEMS Group currently has subsidiaries in 36 countries, one of which is India, the 2015 Hannover Messe partner country. NORD India staff will be present at the stand throughout the week to provide comprehensive information about NORD’s activities on the subcontinent and the assembly facilities in Pune.

NORD DRIVESYSTEMS at the Hannover Messe exhibition

13—17 April 2015, Hanover, Germany

Hall 15, Stand H31