www.industryemea.com

20

'22

Written on Modified on

FPT INDUSTRIAL INAUGURATES ITS NEW ePOWERTRAIN PLANT IN TURIN. THE FUTURE OF CARBON-NEUTRAL MOBILITY STARTS HERE

FPT INDUSTRIAL INAUGURATES ITS NEW ePOWERTRAIN PLANT IN TURIN. THE FUTURE OF CARBON-NEUTRAL MOBILITY STARTS HERE.

This opening marks another important milestone for the brand in its decarbonization path and for its strategy of achieving net-zero emissions for its products and of all its industrial activities.

The new production site is the first totally carbon-neutral Iveco Group plant, achieving its targets by offsetting its CO2 emissions with the purchase of energy from renewable sources and carbon credits. In addition, the plant generates energy with solar panels installed on the façade and with innovative technologies, such as the “mini-wind tower” and the “smart flower”.

In the new ePowertrain plant attention to environmental protection is also shown through the Iveco Group Sustainability Garden, a 6,000 square meter internal space planted with 100 drought-resilient plants of native species with great CO2 absorption capacity. A pedestrian path has also been created with recycled pallets. Along it four panels, also made with recycled pallets, illustrate the Group’s sustainability priorities and related targets.

The Mayor of Turin Stefano Lo Russo and the Councilor for Budget, Patrimony and Productive Activities Development of the Piedmont Region Andrea Tronzano attended the ceremony, together with a delegation of professors and students from the University of Turin.

The features of the new FPT Industrial plant, together with the Iveco Group’s business vision, were discussed during a moderated talk featuring Sylvain Blaise, President, Powertrain Business Unit, Iveco Group, Domenico Nucera, President, Bus Business Unit, Iveco Group, Luca Sra, President, Truck Business Unit, Iveco Group, and Annalisa Stupenengo, Chief Operations Officer, Iveco Group.

ADVANCED TECHNOLOGY, SUSTAINABILITY AND SAFETY AT WORK

The new electric-dedicated ePowertrain plant is integrated into the FPT Industrial Stura area, next to testing and the production plant for internal combustion engines, transmissions and axles, with obvious advantages in terms of industrial synergies.

With a total area of 15,000 square meters, the ePowertrain plant features three parallel production lines dedicated respectively to battery pack assembly, electric Central Drives, and HCV electric axle production.

At full capacity, it will produce over 20,000 electric axles and over 20,000 battery packs per year for LCVs, minibuses and buses.

The number of employees is expected to reach about 200 people, while the new ePowertrain plant is already generating additional jobs.

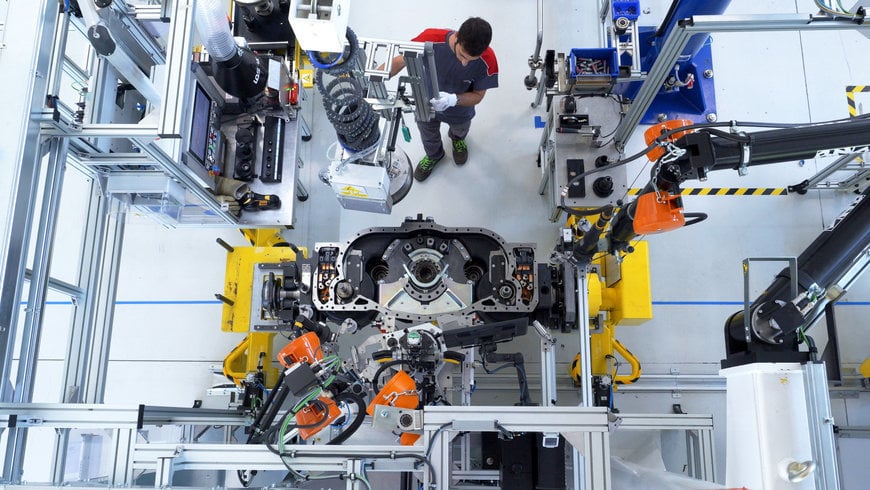

Introducing remarkable innovations on its production lines is a hallmark of FPT Industrial, but at the ePowertrain plant human-machine collaboration has reached the state of the art, thanks to the Industry 4.0 technologies adopted across all areas, enabling the automatic collection and analysis of all data which are essential to monitor and improve safety, quality and productivity.

All production processes are based on highly automated warehouses for the management of components, and developed through electronically controlled assembly stations.

Next-generation technologies adopted include augmented and virtual reality, reducing the design time for production lines by simulating operational outcomes before physical installation; 3D printing and “Smart Observer” systems based on intelligent sensors; 3D scanners for metrology-grade measurements; 3D reality simulators and cooperative robots.

These robots, together with Automated Guided Vehicles, greatly improve ergonomics and safety, and make the operators’ job easier and less stressful.

Cloud quality checks allow instant detection of problems, while end-of-line checks certify the conformity of the product both in terms of configuration, performance and safety.

On the HCV electric axles line, a station with light signals supports the operator by clearly indicating which component is to be selected and where to mount it, thus helping achieve the zero-error target.

On the battery assembly line, dielectric carpets protect operators against possible electric dispersions, while thermal imaging cameras automatically measure battery temperatures, immediately reporting any deviation from the norm.

“As key energy transition players in all On-Highway and Off-Highway sectors, we are pioneering new clean energy propulsion systems and we are fully committed to reaching the ‘net zero carbon’ goal by 2040,” says Sylvain Blaise, President of the Powertrain Business Unit, Iveco Group. “Our new ePowertrain plant is a fundamental step in this process. The electrified products we manufacture here will accelerate decarbonization in the transport sector, providing our partners and customers with cutting-edge solutions for their future product line-ups.”

“People are the key to our success. Our team is called to acquire a new mindset to approach the new challenges of e-mobility, and new skills to relate with the Industry 4.0 environment. It’s a change management,” says Alessandro Sezza, Plant Manager at the Turin site, Iveco Group. “At the Tech Academy, we prepare our people for a completely new process, where it is fundamental to manage the information flows provided by robots and automated tools. But we also teach the soft skills they need, with a tailored programme called ‘In trasformazione’ we prepare our people to face a complex and fluid scenario.”