www.industryemea.com

27

'22

Written on Modified on

Bosch Rexroth adds a modular standard control system for the die cushion function

With a DGUV test certificate to the standard modules IH04, the new IH04 Type E standard modules from Bosch Rexroth for the die cushion function, engineers can work with the most common switching systems.

With the new IH04 Type E standard modules from Bosch Rexroth for the die cushion function, engineers can work with the most common switching systems. Thanks to the standardized safety concept with a DGUV test certificate, the modules meet general safety requirements with minimal outlay. They can optionally be combined with an energy recovery function which reduces the energy consumption of the die cushion module at the same time.

Die cushion technology ensures uniform sheet thicknesses during forming and avoids cracks or wrinkles in the workpiece. The newly developed IH04 Type E (IH04E) die cushion module from Bosch Rexroth complements the IH04 Type C/D standard modules for the upper piston. IH04E is compatible with most popular switching systems for state-of-the-art hydraulic die cushions.

At the same time, as a control system, it meets the requirements for installation in hydraulic presses in accordance with ISO 16092-3 as a "safety- related control system component" with category 4, PLe in accordance with ISO 13849-1. This includes preventing unintentional lowering under its own weight, preventing unintentional start-up from the rest position and stopping the hazardous closing movement. The safely reduced speed reaches category 3. The DGUV test certificate significantly reduces the calculation and documentation work needed for engineers to demonstrate the safety of their machines in accordance with the relevant standards.

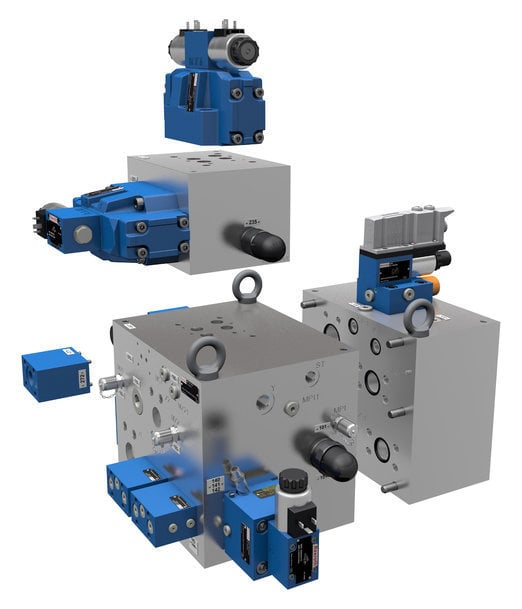

An IH04E comprises a basic module and a directional valve in order to create an “active” die cushion. The basic module provides the tested safety functions. An extension module either provides pretensioning or the prerequisites for sustainable energy recovery. An additional extension module allows differential switching and load sensing.

The IH04E in the nominal sizes NG10 to NG32 caters for pump volume flows of up to 800 l/min at an operating pressure of up to 315 bar.

With IH04 Type S, its hydraulic overload protection system for mechanical presses, Bosch Rexroth offers an additional solution for protecting forming machines. It features an oil cushion between the plunger and the tool for this purpose. In the event of a fault, the load on this cushion is reduced. The load is reduced after just 5 ms to protect the tools as well as the drive and the press frame in the event of overloading. If the plunger is subjected to an off- center load, all connected overload protection systems are triggered at the same time. IH04S is either mounted on the plunger’s oil cushion itself or attached centrally to the plunger and connected by pipes. Compact hydraulic power units complete the overload protection system.

www.boschrexroth.com