www.industryemea.com

08

'22

Written on Modified on

HEIDENHAIN: INTELLIGENT ENCODERS SETTING NEW STANDARDS IN DRIVE SYSTEM TECHNOLOGY

The next generation of inductive scanning, and new compact rotary encoders for motors with rigorous thermal requirements.

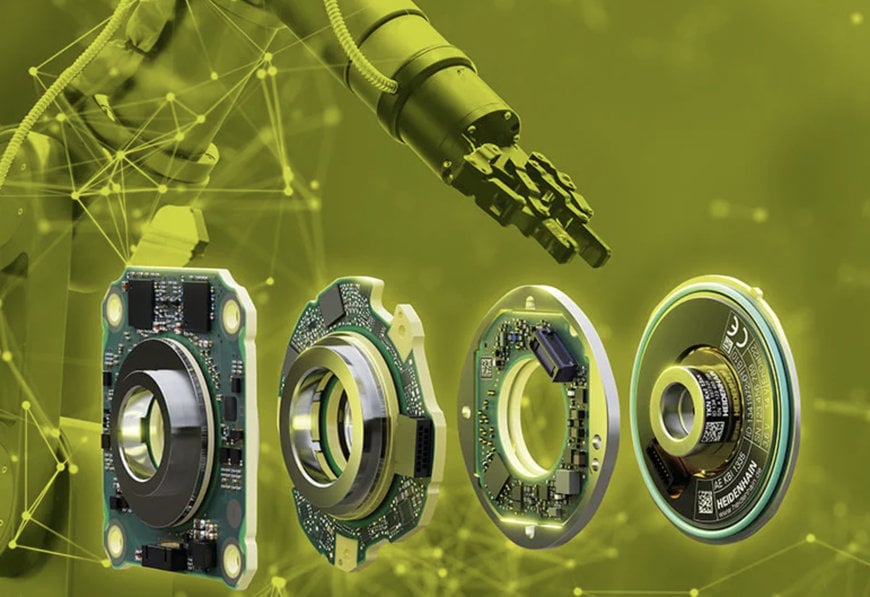

HEIDENHAIN will be presenting two absolute rotary encoders that embody the next generation of inductive scanning: the ECI 1122 and EQI 1134. Their benefits include minimal signal noise, low speed ripple, operating-data collection and less cabling thanks to the EnDat 3 interface. These benefits were achieved by raising the resolution of the singleturn position to 22 bits, which also significantly improves motor control performance. Equipped with the EnDat 3 interface, and therefore connectable with the HMC 2 single-cable solution, the next generation of measurement technology from HEIDENHAIN expands on the many benefits of inductive rotary encoders for motors in demanding automation applications. These benefits include compact dimensions, wide mounting tolerances, contamination resistance, high operating temperatures and immunity to magnetic fields.

Light and compact motor encoders include the KCI 1319 and KBI 1335, now available in new variants: the KCI 1318 FOT and KBI 1335 FOT with the purely serial EnDat 2.2 interface. Their Fan-Out Technology allows HEIDENHAIN to place tracks and electronic components directly on a metal carrier that can also function as a bearing cover. This reduces the number of components and the required space, even dissipating heat through the metal carrier. The disk/hub assembly is press-fit onto the shaft.

More possibilities for advanced robotics: new inductive rotary encoders. Additional variants of our familiar inductive robotics rotary encoders are opening up new applications in advanced robotics:

Starting at SPS, the KCI 120 Dplus dual encoder with motor position and joint position measurement in a single device will be available in three sizes. The centrally positioned scanning unit and two separate disk/hub assemblies are designed for different hollow shaft diameters and installation sizes, giving the HEIDENHAIN KCI 120 Dplus compact dimensions and easy integration with identical functionality. The purely serial EnDat 2.2 interface with functional safety can also be used in safety-critical applications such as human-robot collaboration.

The KCI 120 and KBI 136 are compact rotary encoders for large 30 mm or 40 mm hollow shaft diameters, thus rounding out the selection of HEIDENHAIN rotary encoders designed for robotics applications and bringing the strengths of the smaller 1300 series to significantly more robust and powerful robot motors.

AMO WMRA: secondary encoders for robot motors with large shaft diameters

Designers can significantly improve the absolute position accuracy of their robots by employing an additional high-accuracy encoder at each robot axis. Installed downstream from the gearbox, these secondary encoders measure the actual position of every robot joint. AMO offers the WMRA angle encoder as a secondary encoder. Modularly designed with a scale drum, measuring ring and separate scanning unit, it is ideal for large shaft diameters and difficult installation spaces. Designers can select the diameter of the measuring ring as desired.

From extra small to extra large: Encoders for safety, precision and convenience in medical technology applications

Encoders from HEIDENHAIN and its brands AMO, NUMERIK JENA, RENCO and RSF have proven themselves in medical technology applications for a long time. Their reliability and failsafe performance are key reasons for their use in highly specialized solutions for lab work, therapy and diagnostics in hospitals and physician practices. Due to the benefits for patient comfort and application safety, the high accuracy of these rotary, angle and linear encoders is also becoming more important.

In the fields of lab automation and liquid handing, the RENCO R35i and R35iL rotary encoders ensure high throughput and reliable operation. These incremental rotary encoders without an integral bearing enable particularly fast and accurate positioning on the stepper and BLDC motors used on the many axes and belt motors of automated blood analyzers. The RENCO R35iL even features an amazingly low 8.6 mm profile for the tight installation spaces found in applications such as dialysis machines, blood pumps and metering pumps. It is currently one of the flattest rotary encoders on the market.

When it comes to large medical devices such as CT scanners, the sheer size of the investment calls for safe, reliable and long-term operation. System solutions from AMO perfectly meet these requirements in a medical technology context thanks in part to their touchless, wear-free inductive measurement. They are also resistant to contamination and highly immune to magnetic fields. Solutions are also available for use with high-energy radiation.

In highly automated microscope applications such as in-vitro diagnostics and high-content screening, the HEIDENHAIN LIC 4100 exposed linear encoders enable crisp, detailed imaging data for error-free diagnostics. Their nanometer-level measuring steps and high dynamic performance ensure maximum throughput. As an absolute encoder, the LIC 4100 also outputs the position value immediately upon switch-on with no referencing run, thereby ensuring high process reliability in often complex and time-intensive autonomous analysis processes.

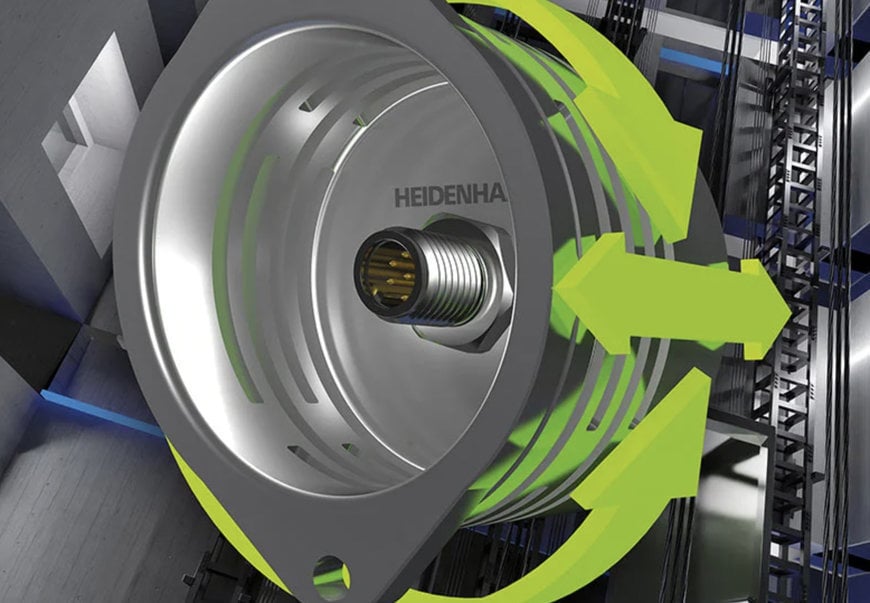

HEIDENHAIN KCI 419 Dplus: the rotary encoder for elevators of the future

In the near future, elevators will no longer need brake-monitoring microswitches. That’s because the HEIDENHAIN KCI 419 Dplus elevator encoders provide not only position feedback for elevator motor control but also valuable additional information.

Mechanically coupled to the armature plate of the brake, the KCI 419 Dplus can detect the brake stroke. Based on the resulting data, the downstream electronics can determine whether the brake is released or engaged, as well as the level of wear. Due to its close proximity to the motor and the brake, the KCI 419 Dplus elevator encoder also delivers relevant data for temperature monitoring without additional sensors, also allowing malfunctions to be identified. The cabling of the entire system is greatly simplified: all of the parameters are transferred over one cable with the EnDat 2.2 purely serial interface. Other benefits are improved possibilities for remote monitoring and predictive maintenance. In the field of elevators, the KCI 419 Dplus provides greater availability and reliability, as well as considerable labor savings for mounting, cabling, adjustment and maintenance.

HEIDENHAIN ECI 1119 PressFit and EQI 1131 PressFit: Inductive rotary encoders for automated mounting in small axes

The ECI 1119 PressFit and EQI 1131 PressFit absolute rotary encoders from HEIDENHAIN are ideal solutions for fast and reliable installation. These compact rotary encoders are suitable for motors with a flange size of just 40 mm x 40 mm and an axial height of only 20 mm. Mounting begins with a tolerance sleeve inserted into a hole in the motor housing. The rotary encoder is then press-fit with its PressFit flange and fastened to the mating shaft via one central screw. This saves space and enables automated installation. Force measurement allows the process to be monitored.

EnDat 3: digitally integrate your encoders

Continuously developed and ready for the future of digitalization: meet the EnDat interface from HEIDENHAIN. EnDat makes the process of integrating encoders into systems easy and reliable. HEIDENHAIN will demonstrate EnDat 3 bus operation with three different encoders transmitting position, sensor and monitoring data at a 30 µs cycle time. A measuring arm setup will also be demonstrated, with an encoder on each joint transmitting its position data using EnDat 3 in bus operation. This reduces cabling while providing functional safety and extensive diagnostic possibilities. EnDat 3 is the optimal encoder interface for high system integration and for meeting the requirements of the digital future at reduced system costs and with flexible machine architectures.

RTMB+, TUCANA ST and AQUARIUS ST from ETEL: more possibilities for turret handling

Advances in the semiconductor and electronics industry are largely driven by miniaturization, but packaging and inspection processes require handling comparatively large components with maximum process reliability and performance. The RTMB+ indexing tables from ETEL combine high speed with high load capacity for precisely these applications. Meanwhile, the TUCANA ST and AQUARIUS ST short-stroke actuators prevent turret handlers from subjecting chips and wafers to loads during packaging and inspection.

www.heidenhain.com