www.industryemea.com

16

'22

Written on Modified on

Battery production: Dürr provides CATL with innovative technology for electrode production

The Dürr Group continues its expansion in the new business field of battery production. The mechanical and plant engineering firm is delivering an innovative technology for the sustainable manufacture of lithium-ion batteries. This will be used in CATL’s plant that is currently being built in Arnstadt, situated in the German state of Thuringia.

CATL highly focuses on resource reusability and sustainability. The order placed in early 2022 comprises several systems based on an eco-friendly process for solvent recovery in production. This prevents tens of thousands of tons of CO2 from being generated every year and enables the solvent to be reused multiple times. The CATL plant in Thuringia is the Chinese world market leader’s first production site in Europe. In the wake of electromobility, production capacities for lithium-ion batteries in Europe are expected to increase significantly over the coming years.

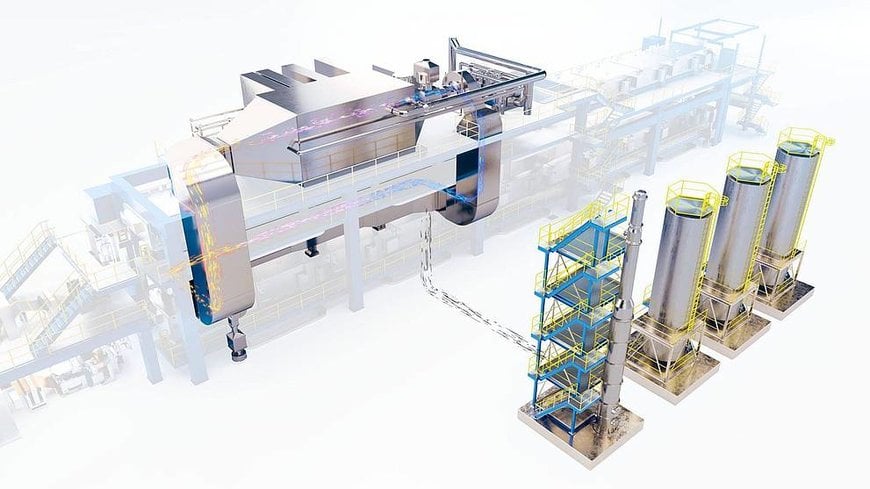

In battery factories, solvents are used in the manufacture of electrodes, more specifically in the coating of electrode foil. CATL’s plan in Arnstadt is to run multiple coating lines, each of which will be equipped with a Dürr system for solvent recovery. This makes production not only eco-friendly but also efficient, because the solvent used is expensive and must therefore be recovered and fed back into the production process for multiple use. Dürr’s Sorpt.X LC technology, in combination with a distillation system, ensures over 95% of the recovered solvent can be reused at the required quality.

Dr. Jochen Weyrauch, CEO of Dürr AG, said: “With CATL we have gained another customer in the up-and-coming market of battery production technology. Our technology will make a major contribution in helping CATL produce its electrodes in a way that is both sustainable and economical.” He also emphasized the importance of the battery sector for electromobility: “More battery cells are required for electromobility to prevail. This is leading to the construction of new battery factories, especially in Europe. The production processes these use ultimately play a critical role in determining the size of an electric vehicle’s environmental footprint.”

Cooperation for further growth in battery production

The Dürr Group is planning further growth in the business field of battery production. In September, the company therefore announced its alliance in the battery sector with the German mechanical engineering firms Grob and Manz. The three partners want to combine their technologies and expertise to establish themselves as an end-to-end supplier for the equipment of entire battery factories. This market is currently dominated mainly by Asian mechanical engineering firms. However, many battery manufacturers building factories in Europe would like partners from the European mechanical engineering market, so they can source their production systems locally.

Dürr, Grob, and Manz are addressing this need through their cooperation. In this, Dürr is responsible for electrode manufacture, while Manz covers battery cell assembly and Grob delivers technology for the assembly of the battery packs. Dr. Jochen Weyrauch stated: “The combined technology offering of Dürr, Grob, and Manz makes for highly efficient manufacturing processes with maximum digitalization, a high level of availability, and excellent product quality. This enables both mass and premium manufacturers to produce exactly the right battery types for their requirements.”

Electrodes are an integral part of every lithium-ion cell. Dürr’s process, which is established in the battery industry, uses the solvent N-Methyl-2-pyrrolidone (NMP) to dissolve the active materials employed in electrode coating. Classed as a hazardous substance, NMP must be used with utmost care. However, due to its excellent properties as a solvent, it is indispensable in series production. Furthermore, at around € 3,100 per ton, NMP is an expensive operating material. These reasons have led Dürr to develop an innovative, closed-loop solution. Dürr’s Sorpt.X LC solvent recovery system removes solvents from the exhaust air of electrode coating systems, while recovering the heat and 99.9 percent of the NMP contained therein. Thanks to Dürr’s technology, the solvent concentration in the air emitted to the atmosphere is only 1 mg/m3.

Ken Zak, CEO of Dürr’s Clean Technology Systems division, declared: “Thanks to its high level of efficiency, the patented Dürr solution enables the recovery of 99.9 percent of NMP, of which over 95 percent can be reused in the coating process after distillation. Plus, the new solvent recovery system enables us to achieve excellent emission levels, which meet the most stringent local and global requirements.”

www.durr.com