www.industryemea.com

27

'23

Written on Modified on

Rotair: Laying the Foundations for the Digital Future

Fibre Fever and the Role of Compressed Air in Meeting Demands for Next Generation Access, Fibre Optic Cable based High-Speed Data.

Today, more and more businesses and consumers are demanding reliable high speed data connections, through air waves (such as WiFi, Bluetooth or GSM signals) or by cable. This demand has only grown following the Covid pandemic and the increased use of ‘smart working’ from home. The European Commission has set clear goals for connectivity speeds by 2025: at least 100Mbps for all European households and 1000Mbps or 1Gbps for all main socio-economic drivers (such as schools, research facilities, hospitals,…). The accelerated roll-out of fibre optic cables throughout Europe is a large part of the answer and to achieve this efficiently, compressed air has a surprisingly important role – some may even say that compressed air is the silent workhorse behind meeting the connectivity challenges of the future.

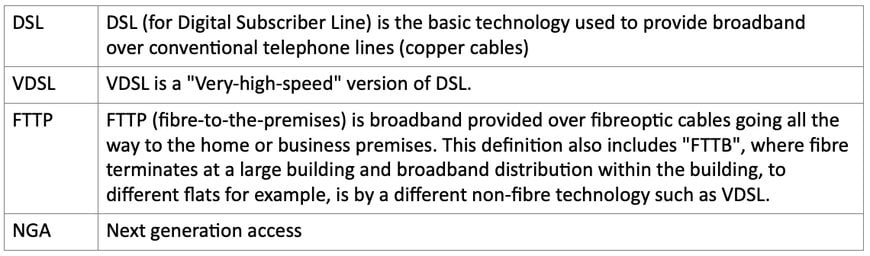

Call-out box

Technology Definitions

Fibre Fever in Europe

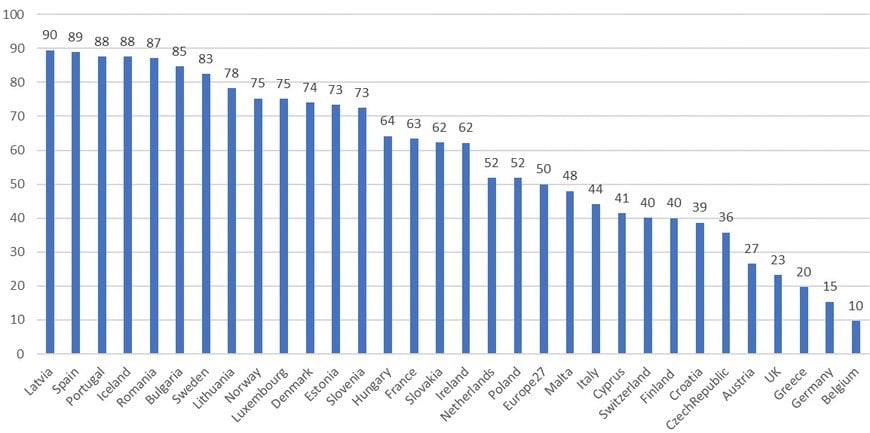

According to a 2021 EU Commission study on Broadband coverage in Europe, from June 2020 to June 2021 there was a 7% increase in the number of homes passed by FTTP networks – reaching 50.0% of EU homes in total. Despite this, there were still thirteen countries recording FTTP coverage below the EU average. However, the relentless fibre fever continues and is only set to accelerate as more countries recognise that upgrading existing (copper) cables imposes limits on the future speed and performance of connections. Across the EU in the latest study period (June 2020 to June 2021):

Six countries reached FTTP coverage levels higher than 80%: Spain, Portugal, Iceland, Romania, Bulgaria, and Sweden

Nine countries recorded double-digit growth in FTTP coverage: Cyprus, France, Hungary, Ireland, Italy, Lithuania, the Netherlands, Romania, and Slovakia.

FTTP coverage expanded more quickly than other fixed broadband technologies in rural areas. Rural FTTP availability increased by 8.0 percentage points, reaching a third (33.8%) of rural EU households.

Challenges of fibre optic cable laying

Countries are increasingly turning to fibre optic cables, despite the additional infrastructure required in installation, because one of the biggest advantages of fibre optics is that they can handle much more data than older copper cables. Overall, fibre optic cables have a higher bandwidth, which means they can carry more information. However, this means new cables versus upgrading existing copper cables – and this commonly requires digging a trench and laying the tube in the trench, to which the fibre optic cable is then inserted Fibre optic cables consist of glass threads, each capable of transmitting digital data modulated into light waves. They effectively send information coded in a beam of light through a glass or plastic pipe. Given the importance of preserving the integrity of the cables, utmost precision in process is required.

Preparation

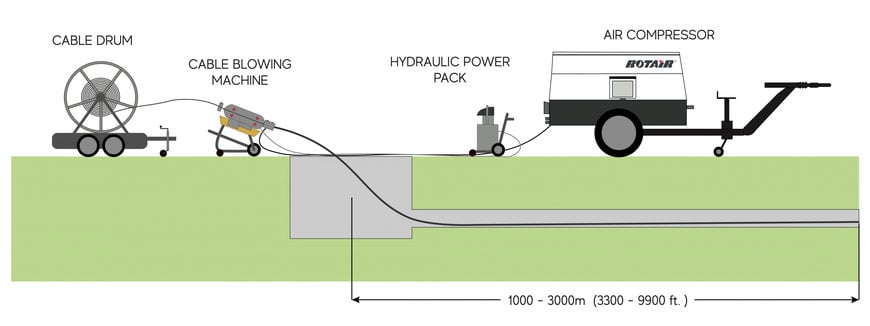

Cleaning of the tube is important to ensure success in the whole process, minimising friction when blowing the fibre optic cable later on. To do this, a sponge is blown through the tube with 14 bars of air pressure to remove the initial dirt. Then another sponge is blown through the tube, this time with a lubricant to reduce friction.

At this stage when the fibre optic cable is mechanically fed into the tube by the blow-in machine, it is critical to maintain a constant and reliable air flow at 14 bar as up to several hundred metres of fibre optic cable is fed into the blow-in machine from the reel car, itself which should be positioned correctly to ensure unobstructed cable feeding.

The environmental impact of fibre

The growing attention to climate change leads to more awareness of the environmental impact of technology. In that context digitization is one of the leverages for a lower CO2 emission as it leads to the creation of new applications which make it possible to work more efficiently and to save energy. The use of fibre raises the level of digitization, so that multiple sectors can become greener.

Fibre also contributes more directly to a greener society. While the electrical pulses in copper or cable networks need to be boosted, the light signal in the fibre can be sent over longer distances. As such fibre networks work at higher speeds, meaning that by using the same amount of energy more information can be sent.

Single Length Cable Blowing

The Air Compressor role

Cable blowing is the process of inserting an optical fibre cable into a duct by combining a mechanical pushing force (pneumatic, electric or hydraulic) and a high-speed air flow. After the traction rollers in the blowing device pushed the cable for a few hundred meters, compressed air is injected in the duct. By introducing compressed air the cable inside the duct remains in floating condition, which reduces friction between the cable outer surface and duct inner wall. The compressor role is therefore critical in the efficient and reliable installation of fibre optic cables. It is elementary that the compressor is correctly sized for the project, is able to deliver 14 bar air pressure, is able to cool the compressed air close to ambient temperature and has a moisture separator.

Conclusion: Role of technology and specialist advice to optimise efficiencies

As fibre fever across Europe and around the world grows, the reliable and efficient installation of fibre optic cables and the work of its installers will come under increasing pressure. However, by making the necessary preparations, utilising the right equipment and seeking specialised support, companies can avoid costly mistakes and develop the expertise and capability necessary to treat this fever and bring efficient and reliable next generation access to the world.

www.rotairspa.com

Author: Alex Persyn, Director of Product Management ROTAIR Portable Compressors.