www.industryemea.com

12

'23

Written on Modified on

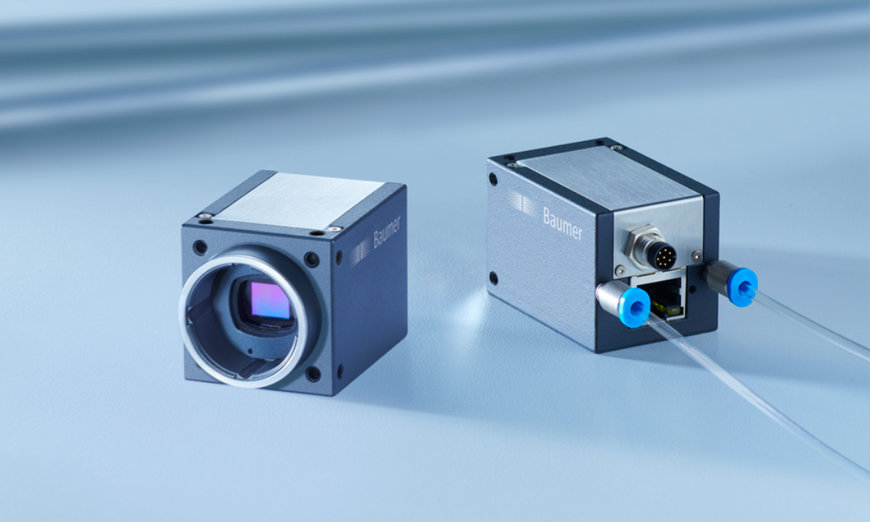

BAUMER PRESENTS INDUSTRIAL CAMERA WITH INTEGRATED COOLING PIPE

Baumer's industrial cameras with integrated cooling pipes ensure temperature stability in a compact design.

Traditionally for high-temperature environments, the camera housing would be surrounded by external cooling components to ensure constant camera temperatures. Such effort is time-consuming and results in additional camera dimensions. To counteract this drawback, Baumer has extended the CX series with cameras with integrated cooling. The patented cooling pipe of the CX.XC cameras winds its way inside the camera housing, saving space and ensuring thermal stability within an instant.

Semiconductor production calls for high-precision measured values

Particularly in semiconductor manufacturing, thermal stability of the cameras is key. In wafer bonding, for example, inspections must ensure that individual wafer markings precisely align with each other. This will achieve high-precision image acquisition since measurement tolerances are within the nanometer range. For such accurate data, thermal stability of relevant camera components during the measurement cycle time is indispensable.

The integrated cooling pipe designed by Baumer offers two decisive benefits: It not only ensures the required thermal stability, but also cools down to constant values within a few minutes, which is significantly faster than achieved with conventionally used external devices. This will save users time since the active cooling by Baumer cuts down on waiting times in data acquisition.

Integrated cooling pipe for constantly low camera temperatures

Unlike external cooling from outside of the housing, the integrated cooling pipe dissipates the heat exactly where it is generated: close to sensor and lens. Thanks to effective heat dissipation, the CX.XC cameras acquire images at very low noise with very few defective pixels. Cooling via integrated pipe utilizes compressed air (2 to 3 bar) or liquids such as water (up to 6 bar). Further to semiconductor production, further application examples for the Baumer cameras with integrated cooling pipe are industries where excessive ambient temperatures prevail: glass and metal processing, large bakeries and many more. The CX.XC cameras deliver reliable image data even at up to 65 degrees Celsius present at the housing.

CX.XC cameras with ultra-precise image acquisition ensure accurately aligned marks in wafer bonding.

The Baumer CX.XC cameras with integrated active cooling are based on the CX series with more than 70 models and hence provide an extensive sensor portfolio for cross-industry standard applications in industrial image processing. Standard variants in 29×29 mm design offer a wide range of functions and feature the latest Sony Pregius, Pregius S, STARVIS, Polarsens as well as onsemi PYTHON CMOS sensors to put future-oriented applications into practice. Models with standard-compliant GigE Vision or USB3 Vision interface, with polarization sensor detecting the linear polarization surface state as well as with global, rolling or global reset shutter allow for multifaceted application solutions.

The CX cameras offer very good image quality and high frame rates – with the use of an ROI (Region of Interest) even with far more than 1000 images/s. Easy camera integration with changing light conditions is ensured thanks to auto features for exposure, gain, white balance, and colour transformation.

www.baumer.com