www.industryemea.com

06

'23

Written on Modified on

Optimizing production processes through modularization

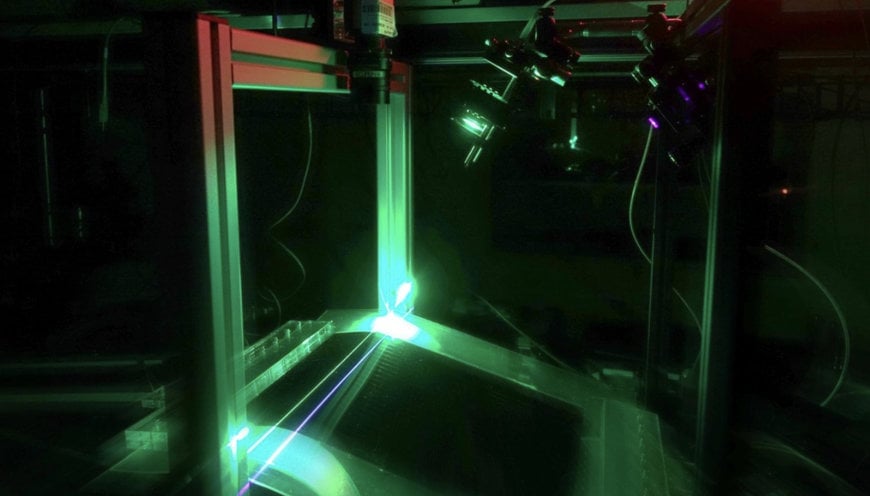

Researchers at the Fraunhofer Institute for Material and Beam Technology IWS have developed SURFinpro, a solution that uses artificial intelligence and optical measurement technology to detect, classify and visualize defects in real time, and report them to the plant carrying out the production.

Ultra-light, ultra-thin, exceptionally reliable, all while reaching rapid production speeds — Dr. Christopher Taudt, group manager for Surface Metrology at the Zwickau-based Fraunhofer Application Center for Optical Metrology and Surface Technologies AZOM, part of Fraunhofer IWS, and his team ensures that product promises like these turn into reality. Together the scientists have developed a system that detects surface defects, artifacts as well as texture changes, and that evaluates them with the support of artificial intelligence.

This process can capture 3D-information of surfaces rapidly and in high resolution. The measurement data is used to generate supplementary information in-line for ongoing production processes. “The system does not just detect defects — it classifies them at the same time and immediately establishes a wider context. Our customers receive information about the type of defect, along with many other parameters like the defect’s density, geometric dimensions and frequency,” adds Taudt. “This represents a significant added value compared to conventional systems.”

Higher precision at greater speeds

The measurement system has been operating successfully in industry for more than a year, analyzing a roll-to-roll process with substrates widths of 70 centimeters. In order to leverage further potential for optimization, Christopher Taudt and the SURFinpro team are training the system within ongoing production using a defect catalog. As defects are reported, they are fed into a neural network, thereby refining the detection accuracy. The researchers use the measurement information to check if new defects occur or existing defects are modified, which requires a dynamic response of the system. “On the one hand, we are working to develop better neural networks that require less data,” explains the scientist, “in addition, we are also developing new training strategies within ongoing operation.”

The experts of the Fraunhofer AZOM are currently adapting their technology to new fields of application, such as continuous fiber-composite manufacturing processes. “Here, our partners are not only interested in avoiding near-surface defects, they also want the technology to be able to identify and assess components in multiple dimensions,” explains Taudt. Another target group that the team envisages for the algorithms and defect-classification system is the semiconductor industry, for example in the production of flexible semiconductor materials.

Currently, the Fraunhofer AZOM solution uses a maximum of four cameras. In a next step, the researchers envision to add additional camera systems. This would be beneficial regardless of the process being assessed, from fiber-composite processes involving very large components to traditional roll-to-roll processes, like those used in the photovoltaic industry, for example.

Another key aspect for the scientists is the system speed. For fiber-reinforced plastics in particular, but also in textile processing, very short cycle times need to be particularly rapid. “Increasing speed is an important issue and we have the expertise to meet these requirements. Our solution uses machine learning and artificial intelligence technologies firstly for the actual analysis, but also in order to accelerate the assessment steps,” explains the group manager, adding: “An effective measurement analysis process consists of a manageable number of individual steps that filter and reduce data. We are continuously developing new technologies in this area in order to make this process even faster and to extract the same amount of information from less data, for example.”

Intelligent and ingeniously modular

The scientists believe that one of the key characteristics of their system is its modularity. Thanks to a sophisticated modularization approach using efficient components, SURFinpro provides a wide variety of potential deployments and is easy to adapt: “Many of the technologies that we use in our system have been developed as standalone components in a way that they can also be implemented effectively in various other contexts and projects.” The Fraunhofer AZOM researchers’ project is a prime example of how successful and practicable this modular approach can be.

This year’s Laser World of Photonics will see Christopher Taudt and his team present their solution, using an example application of a roll-to-roll process for producing flexible solar cells. Visitors to the trade show from June 27 to 30 will be able to see the solution carrying out data capture and analysis of an ongoing process in real time at joint Fraunhofer booth 441 in Hall A3.

www.fraunhofer.com