www.industryemea.com

04

'16

Written on Modified on

Heart support system driven by NSK ball screws

When it comes to medical devices, particularly those relating to the heart, there is no margin for failure – the device must remain operational at all times. With this in mind, the benchmark for quality engineering at Berlin Heart GmbH (a manufacturer of innovative mechanical devices that support the heart) is second-to-none.

EXCOR® VAD emulates the operation of a human heart

In the company’s EXCOR® series, an air-operated diaphragm pump supports the heart’s function or takes over the pumping function entirely, while in the mobile version of EXCOR®, the external artificial heart is driven by a miniature ball screw that is designed and manufactured by NSK. This advanced mobile device emulates the exact way that the human heart functions and under no circumstances is the ball screw allowed to fail.

The human heart is a remarkable machine, offering flow rates of 3 to 4.5 l/min, adaptive control with speeds from 50 to 200 cycles per minute, and typically more than 100,000 duty cycles per day. Unfortunately however, some people’s hearts are unable to function in the correct manner, hence the development by companies such as Berlin Heart of modern heart support systems, or VADs (Ventricular Assist Devices) as they are known in the industry.

Established in 1996, Berlin Heart GmbH is the only manufacturer of VAD systems in Europe and the only company in the world that offers such technology for both adults and children. The youngest patient who was successfully kept alive until a heart transplant could be performed, was only eight days old when he received a VAD.

Excor mobile units manufactured in Berlin and used in many countries around the world

Excor mobile units manufactured in Berlin and used in many countries around the world

Berlin Heart manufactures VAD systems that can be implanted inside the body or remain external. With the latter, cannulae are implanted in the patient and connected with air-operated diaphragm pumps located outside the body (paracorporeal). In the Excor mobile, the NSK miniature ball screw travels 60 to 130 times per minute in a single stroke of up to 55.5mm and pushes a defined quantity of air against the diaphragm that separates it from the cannulae with the patient’s blood circulation.

When the Excor mobile was originally designed, the requirement for selecting the ball screw supplier was the operating life of the shaft, as Nedim Arslan, Engineering Department Manager at Berlin Heart, explains: “The NSK miniature ball screw achieved an impressive operating life of approximately 120 million cycles, which was by far the highest in our benchmark tests."

To ensure absolute peace-of-mind, every three months (around 10 million cycles), the ball screw units undergo maintenance service at Berlin Heart, to clean and grease the shafts among other tasks. With this in mind, NSK implemented specific ball screw geometric modifications at the design stage that make maintenance significantly easier.

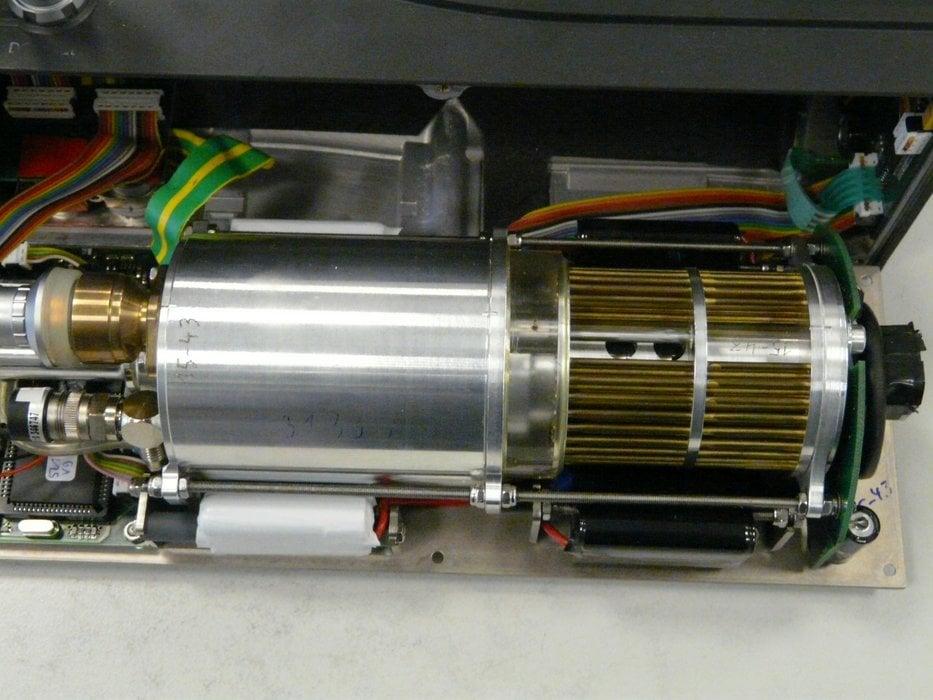

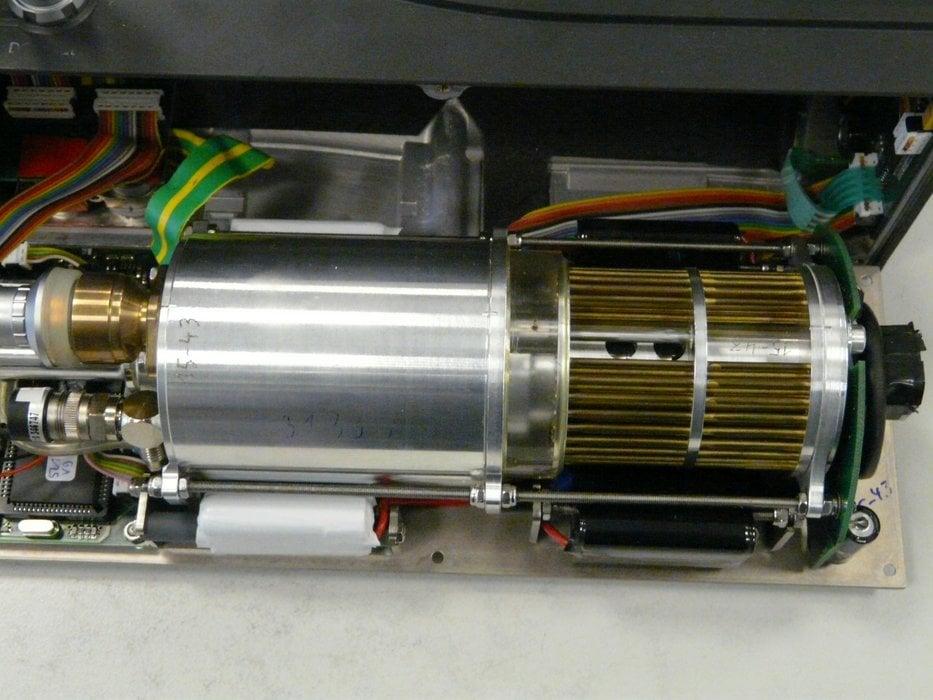

View of the open driving system of the pump. The NSK ball screw is out of sight in the centre of the unit

View of the open driving system of the pump. The NSK ball screw is out of sight in the centre of the unit

A further design stage consideration was the type of grease deployed by the driving system. The fact that the miniature 8mm diameter shafts reach temperatures of 70 to 80°C may seem surprising considering that the servomotors which drive the blood pumps have very low conductance, but it’s an indicator of how much the drive system is stressed. For this reason, it was very important to use grease that is able to operate and survive at these elevated temperatures.

A highly finished miniature ball screw with C3 accuracy class forms the basis of the NSK shaft system used today by Berlin Heart in its Excor mobile. The shafts are manufactured to the customer's requirements and can be considered tailor-made. The parts are also delivered ready for installation as a complete drive module with the corresponding bearing unit.

Only a customer-specific miniature ball screw from NSK can match the stringent requirements of Excor mobile

Berlin Heart has almost 20 years of experience working with paracorporeal heart support and currently assists more than 3800 patients. NSK, as the supplier of the ball screw, has become a trusted technology partner, with the two companies working closely together on numerous occasions to overcome specific design and engineering challenges.

In the company’s EXCOR® series, an air-operated diaphragm pump supports the heart’s function or takes over the pumping function entirely, while in the mobile version of EXCOR®, the external artificial heart is driven by a miniature ball screw that is designed and manufactured by NSK. This advanced mobile device emulates the exact way that the human heart functions and under no circumstances is the ball screw allowed to fail.

The human heart is a remarkable machine, offering flow rates of 3 to 4.5 l/min, adaptive control with speeds from 50 to 200 cycles per minute, and typically more than 100,000 duty cycles per day. Unfortunately however, some people’s hearts are unable to function in the correct manner, hence the development by companies such as Berlin Heart of modern heart support systems, or VADs (Ventricular Assist Devices) as they are known in the industry.

Established in 1996, Berlin Heart GmbH is the only manufacturer of VAD systems in Europe and the only company in the world that offers such technology for both adults and children. The youngest patient who was successfully kept alive until a heart transplant could be performed, was only eight days old when he received a VAD.

Berlin Heart manufactures VAD systems that can be implanted inside the body or remain external. With the latter, cannulae are implanted in the patient and connected with air-operated diaphragm pumps located outside the body (paracorporeal). In the Excor mobile, the NSK miniature ball screw travels 60 to 130 times per minute in a single stroke of up to 55.5mm and pushes a defined quantity of air against the diaphragm that separates it from the cannulae with the patient’s blood circulation.

When the Excor mobile was originally designed, the requirement for selecting the ball screw supplier was the operating life of the shaft, as Nedim Arslan, Engineering Department Manager at Berlin Heart, explains: “The NSK miniature ball screw achieved an impressive operating life of approximately 120 million cycles, which was by far the highest in our benchmark tests."

To ensure absolute peace-of-mind, every three months (around 10 million cycles), the ball screw units undergo maintenance service at Berlin Heart, to clean and grease the shafts among other tasks. With this in mind, NSK implemented specific ball screw geometric modifications at the design stage that make maintenance significantly easier.

A further design stage consideration was the type of grease deployed by the driving system. The fact that the miniature 8mm diameter shafts reach temperatures of 70 to 80°C may seem surprising considering that the servomotors which drive the blood pumps have very low conductance, but it’s an indicator of how much the drive system is stressed. For this reason, it was very important to use grease that is able to operate and survive at these elevated temperatures.

A highly finished miniature ball screw with C3 accuracy class forms the basis of the NSK shaft system used today by Berlin Heart in its Excor mobile. The shafts are manufactured to the customer's requirements and can be considered tailor-made. The parts are also delivered ready for installation as a complete drive module with the corresponding bearing unit.

Only a customer-specific miniature ball screw from NSK can match the stringent requirements of Excor mobile