www.industryemea.com

06

'24

Written on Modified on

Vishay Intertechnology Inrush Current Limiting PTC Thermistors Increase Performance in Active Charge and Discharge Circuits

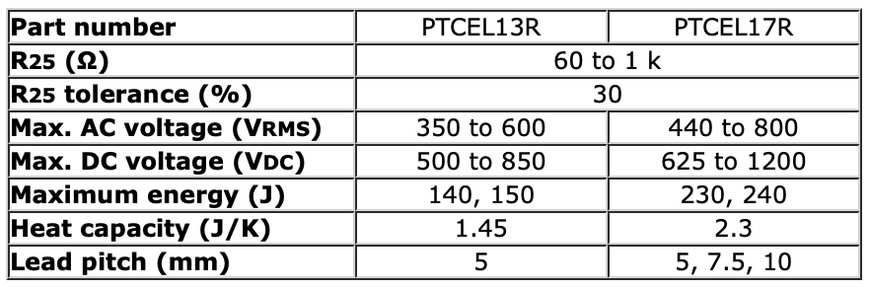

For Automotive and Industrial Applications, Self-Protecting Devices Combine R25 Values to 1 kΩ With High Voltages to 1200 VDC and Energy Handling to 240 J.

Vishay Intertechnology has introduced a new series of inrush current limiting positive temperature coefficient (PTC) thermistors. Designed to increase performance in active charge and discharge circuits for automotive and industrial applications, Vishay BCcomponents PTCEL series devices combine a wide range of resistance at 25 °C (R25) values with high voltage and energy handling capabilities.

Featuring R25 values from 60 Ω to 1 kΩ, the devices released today enable high maximum voltages of 1000 VDC at 500 Ω and 1200 VDC at 1 kΩ, and maximum energy handling to 240 J four times higher than competing devices. By combining multiple thermistors in parallel, energy absorption levels over 1000 J can be achieved. With their high temperature operation to +105 °C, the PTCEL series offers a heat capacity to 2.3 J/K for all resistance values.

AEC-Q200 qualified and self-protecting with no risk of over-heating the thermistors provide overload protection in AC/DC and DC/DC converters; load dump, DC-Link, battery management, and emergency discharge circuits; on-board chargers; home energy storage systems; motor drives; and welding equipment. For these applications, the devices withstand > 100 000 inrush-power cycles and are highly resilient against non-switching peak power up to 25 kW.

The PTCEL series is available in two sizes: the smaller PTCEL13R and larger PTCEL17 for low and high energy applications, respectively. All devices are available in tape on reel packaging and offer a leadwire pitch of 5 mm. In addition, the PTCEL17R is available with leadwire pitches of 7.5 mm and 10 mm to accommodate their higher voltages and can also be automatically handled by pick and place equipment for lower placement costs.

The barium titanate thermistors consist of a ceramic pellet soldered between two tinned CCS wires and coated with a UL 94 V-0 compliant high temperature silicone lacquer. The RoHS-compliant devices are C-UL-US recognized under file E148885 for AC and DC use, providing an increased and controlled safety level. SPICE and 3D models for the PTCEL13R and PTCEL17R are available. Samples and production quantities of the PTCEL series are available now, with lead times of 12 weeks.

Device Specification Table:

www.vishay.com