www.industryemea.com

27

'24

Written on Modified on

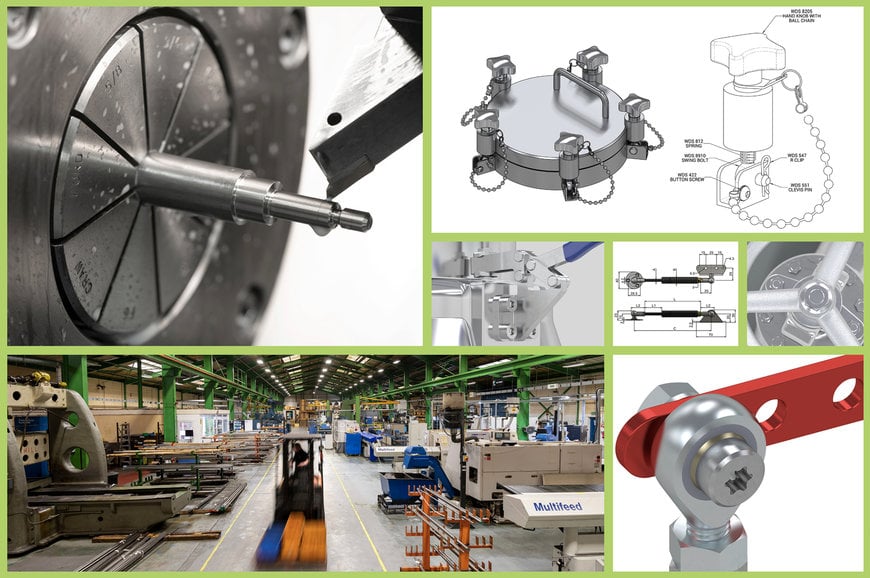

Inside the component factory: How standard parts are designed and manufactured

WDS Components offers standard parts and components to OEMs and end users globally, utilizing in-house designing for optimal specifications and a manufacturing plant for quality and consistency.

On a production line, if a component, such as a clamp or a pin, were to fail, the downtime it could cause to a machine or conveyor could incur a cost stretching to thousands of pounds. On a ship at sea, the consequences of a broken handle could cost more than money alone. Standard parts and components play a crucial role throughout engineering, and where this applies, it’s important to know their provenance.

For an OEM that relies on quality and durability, or for an end user of a critical application, understanding the design and manufacturing processes of a standard part or component can be integral to the specification procedure.

“New standard parts and components often come from a bespoke request,” explains Sam Wilkinson, who heads up the technical team at WDS Components. “For example, it could be a standard part that needs a special coating, like anti-static, or for a very harsh, corrosive environment. Alternatively, it could be special design that requires exacting dimensions, such as castor wheels designed to a specific height to enable a precise clearance, or a handle intended for a compact location.”

In-house design

For some sectors, such as aerospace or scientific research, the critical requirements may mean that the specification is rigid, irrespective of cost. However, to ensure a commercially viable design, the principles of design for manufacture (DFM) usually apply to all new products.

“The first stage is understanding what the customer really needs, and how this relates to manufacturability,” explains Sam. “We review the specification, including aspects such as the form, precision, weight, and materials, determining how critical each criterion is.”

The required quantity is another important factor. Combined with the design specification, this informs how the part should likely be manufactured, and therefore, how it should be designed. This forms a feasibility study, and the approach to each new product design can differ radically, from a stainless steel part that requires CNC turning, to a plastic component intended for manufacture on a 3D printer.

“Then we move into CAD drawings, starting with sketches, and then a 3D model, which we use to create a prototype,” explains Sam.

Communication with the manufacturing plant

From the initial design concept, through to prototyping, there’s often a lot of communication between the customer, the WDS design team, and, based alongside at WDS’ Leeds plant, the WDS manufacturing department. Discussions about aspects ranging from materials selection to dimensions help to identify the optimum balance of attributes.

Working through various iterations of the prototype, this stage also includes testing to ensure the product achieves what the customer wants it to do, in the environment its intended to perform in. This could involve hardness or strength testing, through to aspects such as temperature resistance or ingress protection. Conformance certification, relating to factors such as the grade of stainless steel, is also provided to the customer.

“When the prototype has been finalised, we create a 2D manufacturing drawing with annotated information for the shop floor,” explains Sam. “Then, along with the prototype, this goes through an approval process, in line with ISO9001, that also requires sign-off from the production and quality managers.”

Quality assurance

Only when the customer approves the final design, is the part ready for manufacture. Many bespoke parts that could appeal to wider applications also make it into the WDS catalogue, but not all the WDS range derives from custom designs. Often, the design or product marketing team look to improve on existing standard parts, or they come up with entirely new styles based on innovation.

While WDS works with external suppliers, most of its range is manufactured onsite. The complete range of manufacturing services includes CNC machining, plastic injection moulding and machining, sheet metal pressing, and metal casting. WDS also has an in-house assembly team.

“The advantage of in-house manufacturing is three-fold,” says Sam. “First, it enhances product design, by enabling shared expertise to optimise the final product. It also gives us much greater control over product quality of final manufactured parts. Finally, it provides greater flexibility over stock control, enabling us to quickly replenish our product lines, even to deal with large, repeat OEM orders.”

Rapid global supply

When a new part is finally manufactured, there’s a further inspection, where the part is checked against the approved manufacturing drawing. The parts are then moved to the adjacent warehouse or shipped directly to the customer. All stock items are uploaded in website, including free to download CAD drawings and full technical specification.

“As we can achieve high volume, this not only achieves fast supply for the customer, but it also means that usually, we can pass on this saving to provide them with a cost advantage,” concludes Sam.

www.wdscomponents.com