www.industryemea.com

06

'24

Written on Modified on

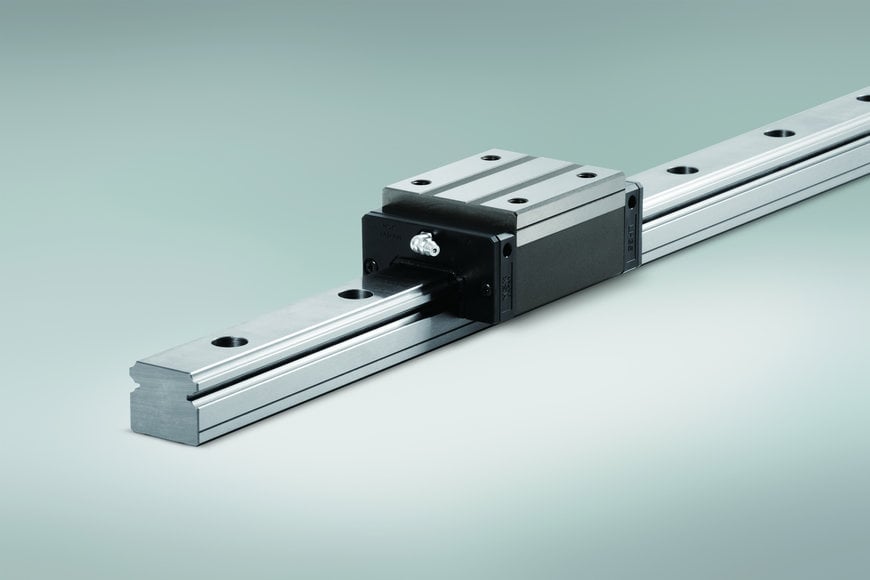

New cutting facility will reduce lead times for European users of NSK linear guides

European users of NSK’s class-leading linear guides can now take advantage of NSK’s new state-of-the-art cutting facility in the Netherlands.

At capacity, the new NSK linear guide cutting facility will output more than 1000 pieces per week

Based at the company’s European Distribution Centre in Tilburg, the €1.6 million plant will enhance service levels for customers in key European markets that include Germany, France, Italy and elsewhere.

The opening ceremony will take place on 15 May 2024. Featuring guided tours of the cutting plant, live demonstrations and presentations highlighting NSK Europe’s commitment to innovation and quality, the event marks a significant milestone in the company’s journey towards excellence in manufacturing. Although NSK Europe already has a linear guide cutting facility at its site in Newark, UK, the addition of Tilburg will help to optimise the company’s service level for these popular products across mainland Europe.

Eduardo Rodriguez, Director Seiki MU Linear Motion and Sector Director Industrial Services at NSK Europe, says: “With customers across Europe demanding faster delivery and response times, the new plant in Tilburg will allow us to deliver linear guides anywhere across the continent in a matter of days. Located in the heart of Europe, the Tilburg site triples our existing capacity and, with quality guaranteed, we are better placed than ever to respond quickly to the needs of our customers.”

The opening of Tilburg linear guide cutting facility means NSK can offer a seven-day delivery time anywhere in Europe. This meets with demands from customers using these high-quality products, particularly those manufacturing automated handling systems, packaging equipment and other common industrial machines such as metal shears. In such applications, precise sales forecasting is difficult, so manufacturers will often order linear guides at short notice. A rapid response from NSK is paramount.

At the Tilburg plant, NSK Europe’s expert production team can cut linear guides to custom lengths, add chamfers to the rails, grind button rails, change the preload, assemble sliders into rails, laser mark customer references, wash the products and provide industry-leading packaging services to prevent any potential for damage during transit. Upon reaching full capacity, the ISO9001-accredited facility will achieve a production output of more than 1000 pieces per week.

All of this is good news for users of NSK linear products, both ball- and roller-based solutions. For instance, growing numbers of manufacturers are taking advantage of the company’s NH/NS series linear ball guides, which offer 1.3 times higher dynamic load ratings and twice the life of conventional guides. NH/NS series linear guides are compatible with a variety of options, including lubrication units and dust-resistant seals, while complete interchangeability allows free matching of the rail and slide.

Similarly, NSK’s RA series linear roller guides deliver long operating life and high load capacity. Users also benefits from high dust resistance and maintenance-free operations, while the optimal size of roller ensures high stiffness values and reduced vibration.

Operating alongside the new Tilburg plant, NSK Europe’s existing linear guide cutting facility in Newark will continue to serve customers in the UK and Ireland.

The new NSK linear guide cutting facility in Tilburg offers a seven-day delivery time anywhere in Europe

www.nsk.com