Mvtec using machine vision without prior programming skills

Automation in the industrial sector is advancing inexorably. A high degree of networking and digitalization is required along the entire value chain.

www.mvtec.com

For this, investments in the right technologies are indispensable. Machine vision is an area that offers enormous potential. However, companies are often reluctant to make use of this potential. A lack of qualified personnel and a lack of programming skills among the employees are frequently cited as reasons for not using machine vision. But this does not have to be the case: Thanks to easy-to-use machine vision software such as MERLIC from MVTec, any company can easily and quickly leverage the benefits of machine vision – without any programming skills.

Most industrial sectors today rely on a very high degree of automation in their value chains. To meet the requirements of industry 4.0 and the smart factory, production processes must be networked and digitalized end-to-end. Machine vision can make a valuable contribution in numerous areas. Functioning as the “eye of production”, it monitors all manufacturing, quality assurance, and intralogistics processes. This involves two components: hardware, in the form of image acquisition devices such as cameras or sensors strategically placed in the production environment that continuously capture and generate substantial volumes of digital image data, and software.

What can machine vision do?

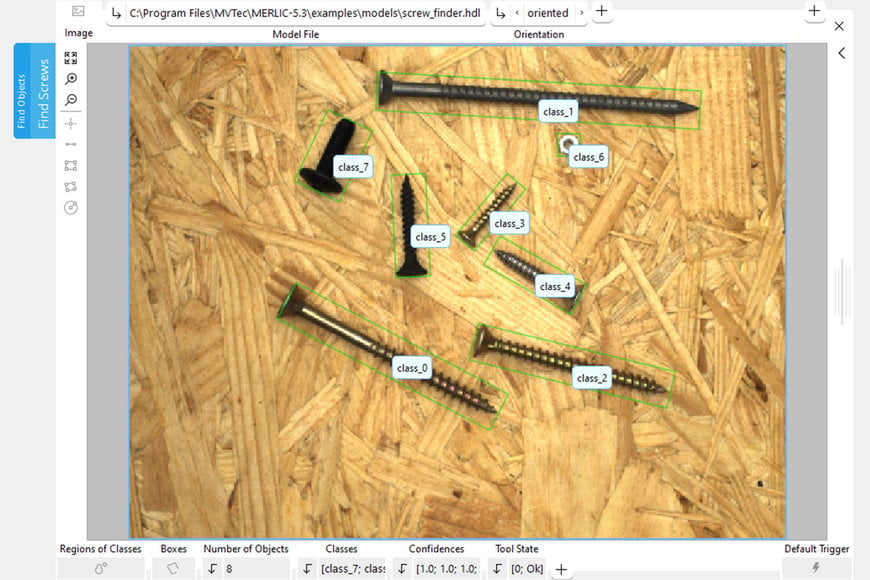

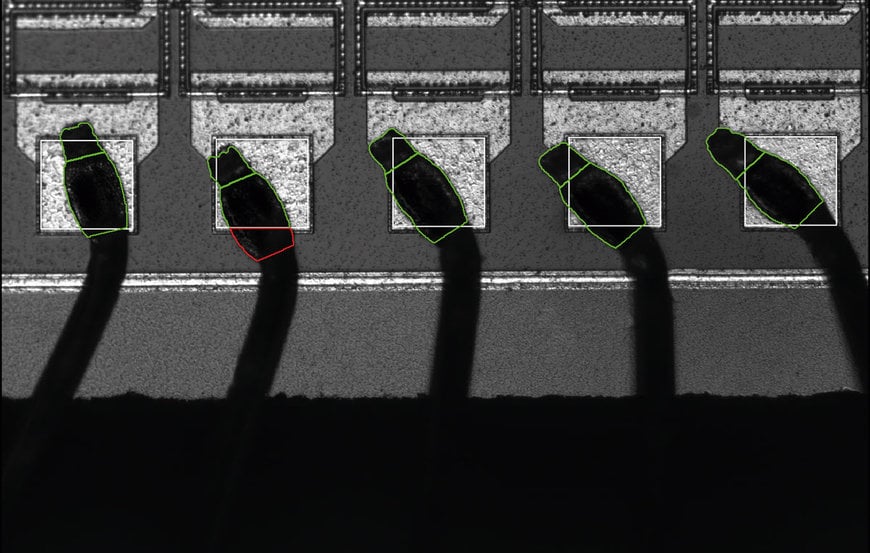

The technology is indispensable for modern, highly automated inspection processes as part of operational quality assurance. It can be used to reliably detect any type of defect in objects. Using optical character recognition (OCR) technologies, objects are recognized not only based on shape and texture, but also based on imprinted combinations of numbers and letters. Machine vision not only enables precise positioning and alignment of workpieces but also aids robots in gripping, handling, and depositing objects accurately, eliminating the need for direct operator intervention. This automation enhances the efficiency and safety of the entire handling process.

Whether in traditional manufacturing, automotive production, machinery and plant engineering, electronics manufacturing, battery production, or even the food and beverage industry – machine vision can be used across these and many other industries. It not only operates very quickly, but also very precisely. Processing large amounts of digital image data takes place in a few milliseconds, providing very accurate, reliable, and robust results. Thus, thanks to modern machine vision, companies can save significant costs – whether in assembly, quality assurance, or logistical workflows.

Easy to use

The integration of professional machine vision applications is usually very complex. Since no programming skills are required for such machine vision software, industrial image processing can thus also provide a valuable contribution to digitization for small and medium-sized companies in various industries, where qualified personnel or corresponding programming skills are often scarce. Here, easy-to-use machine vision software like MVTec MERLIC can provide a solution.

As an all-in-one solution, MERLIC can be easily integrated into factories thanks to its support for all common industry standards and compatibility with a wide range of hardware. It includes all necessary functions such as image acquisition, image processing, and visualization, i.e., the display of results in a frontend. Particularly important, especially for machine vision beginners without programming skills, is the easy-to-use aspect. The tools required to create the machine vision application can be conveniently selected via drag & drop from MERLIC’s graphical user interface. This allows complete machine vision applications to be developed and operated quickly without writing a single line of code. Simple integration into existing control concepts is also possible at any time.

MVTec MERLIC also addresses the increasing importance of artificial intelligence (AI) in the industrial context with its integrated deep learning technologies. Using self-learning algorithms, outstanding results can be achieved in object and defect detection. If neither the amount of high-quality image data, nor the powerful hardware required for training are available, or if one is dealing with very high production speeds, classical rule-based methods are often the better alternative. MERLIC also provides a variety of industry-proven processing tools for this purpose.

www.mvtec.com