www.industryemea.com

19

'24

Written on Modified on

AIR LIQUIDE INNOVATIVE CO2 LIQUEFACTION TECHNOLOGY SELECTED BY STOCKHOLM EXERGI FOR WORLD-SCALE CCS PROJECT

Air Liquide will provide the CO₂ liquefaction technology and equipment for the BECCS project to be built at an existing heat and power biomass (bio-cogeneration) plant in Stockholm.

www.airliquide.com

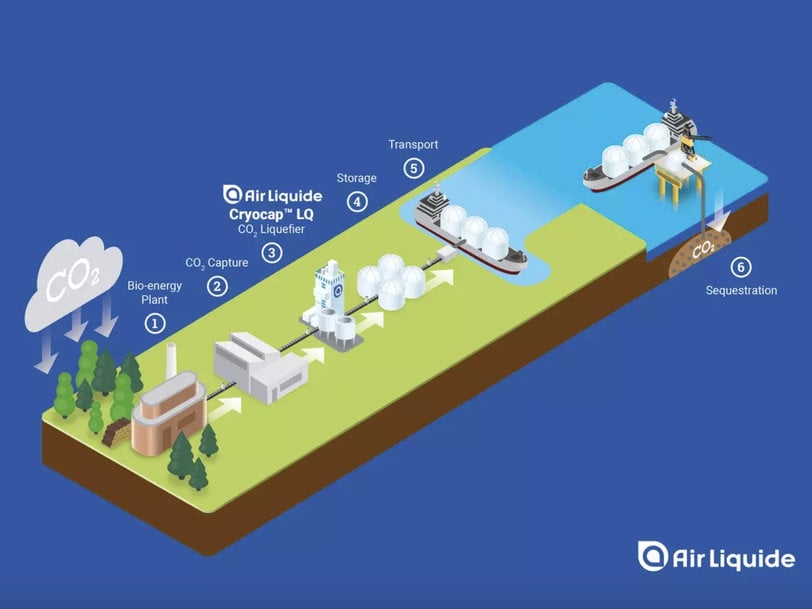

Air Liquide's innovative large-scale CO₂ liquefaction technology, Cryocap™ LQ, has been selected by Stockholm Exergi, Stockholm’s energy company, to contribute to its Bio-Energy Carbon Capture & Storage (BECCS) project. This new technology is an important additional brick in Air Liquide’s portfolio of proprietary technologies that paves the way to developing large-scale Carbon Capture & Storage (CCS) value chains. The CO₂ liquefaction solution allows to transport CO₂ over long distances to carbon sinks for permanent storage, contributing to the viability of CCS projects and emergence of a low-carbon industry.

Under the framework of the agreement, Air Liquide will provide the CO₂ liquefaction technology and equipment for the BECCS project to be built at an existing heat and power biomass (bio-cogeneration) plant in Stockholm. The Cryocap™ LQ CO2 liquefaction unit supplied by Air Liquide will be one of the largest in the world with a capacity of 3,500 tonnes per day. After liquefaction, the CO₂ will be transported for permanent storage. The BECCS facility aims to liquefy and store around eight million tonnes of biogenic CO₂ over the first 10 years of operation. The BECCS project is supported by the European Innovation Fund, one of the world’s largest programs for promoting innovative low-carbon technologies.

Air Liquide Stockholm Exergi EN infography

Air Liquide’s innovative Cryocap™ LQ technology, leveraging Air Liquide’s mastery and expertise in cryogenics, stands out with its chemical-free, non-flammable process and compact design. This cutting-edge setup will also enable the recovery and reuse of heat generated from the process in order to supply Stockholm’s district heating network. These features allow enhanced sustainability and safety as well as best-in-class energy efficiency compared to traditional liquefaction solutions.

www.airliquide.com