Svendborg BrakesTM shows tools to accelerate wind turbine servicing at WindEnergy Hamburg 2024

The maturity and scale of the European wind turbine fleet presents operators with a challenge: how to effectively improve the performance and value of existing equipment?.

Svendborg BrakesTM, a brand of Regal Rexnord, has innovative service tools that accelerate and simplify onshore and offshore turbine maintenance. Consequently, operators have seamless access to aftermarket and original equipment supplier (OES) support to reliably turn motion into renewable power.

Visitors to WindEnergy Hamburg 2024 can discover innovative service tools, products, and solutions to their wind power challenges with Svendborg Brakes experts in Hall B1.EG, Stand 429 from the 24 – 27 September.

Blowing away service challenges for wind turbines

The planning challenges and increased costs associated with new wind energy developments in Europe has made maintaining the existing fleet imperative. Harnessing its 40 years of experience and support of over 200,000 onshore and offshore wind turbines globally, Svendborg Brakes is helping operators achieve this.

Its Yaw Brake Lifting & Installation Tool expedites and simplifies the replacement of yaw brakes. A turbine can feature up to 20 individual yaw brakes located high above ground, each weighing anywhere from 60 kg to 200 kg. The tool allows brake changeovers to be completed in-situ uptower, with service teams safely and easily winching units up and down as needed. The benefits of this approach were apparent in a recent project for an operator of offshore turbines on the coasts of Denmark and the UK. Using the tool allowed the replacement of a multitude of damaged yaw brakes in three days, with only a day and a half of true downtime. This fast maintenance turnaround dramatically reduced costs for the operator.

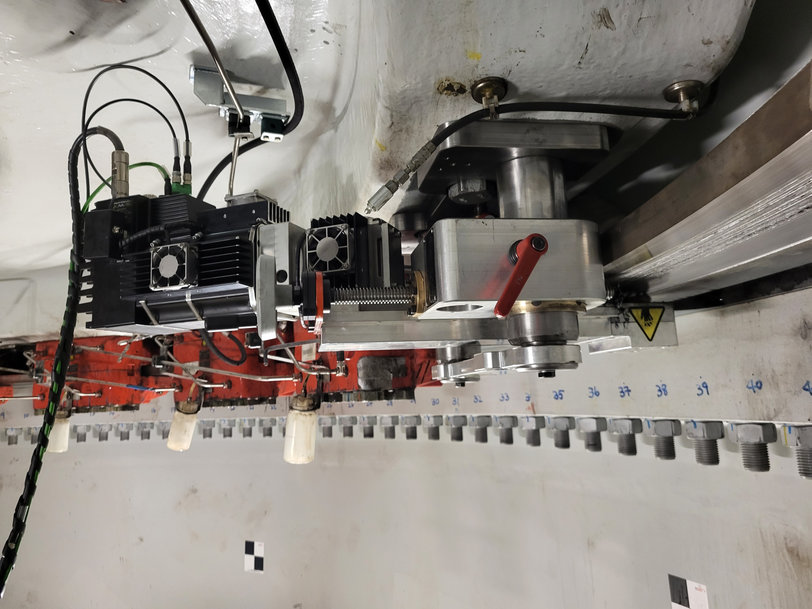

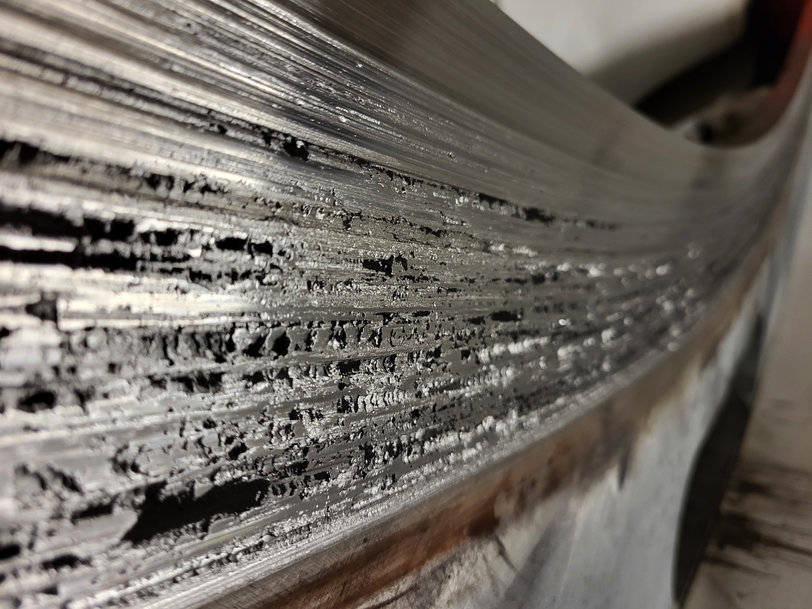

During operation, a yaw disc will experience wear, resulting in imperfections that can reduce braking performance and service life. Svendborg Brakes Disc Resurfacing Tools offer a way to efficiently remove these defects, as was demonstrated for a customer operating an offshore turbine suffering from increased brake pad wear in Scotland. A mobile, lightweight single-axis CNC milling machine, the tool mapped the disc surface and created a program to promptly remove imperfections. A key benefit for the operator was that there was no need to remove the turbine nacelle, avoiding the significant investment required to conduct this procedure offshore. Upon completion, optimal brake performance was restored with the tool providing a more sustainable option to scrapping components and manufacturing new replacements.

A worn yaw disc before resurfacing.

Visitors to the Svendborg Brakes stand will be able to view such tools, as well as additionally discuss the use of its Piston Extractor for safe and fast removal of yaw brake pistons, and the Universal Control Case, which allows Industrial Internet of Things (IIoT) capable remote performance monitoring and root cause analysis for critical wind turbine systems. Also of note is the Groove Tool, which cuts a shaped groove into the yaw brake disc to prevent glazing and reduce noise in operation.

Following resurfacing, yaw disc imperfections are removed, restoring braking performance.

Products, parts and support for every wind direction

Supplementing its exceptional aftermarket support, Svendborg Brakes also offers a complete range of hydraulic rotor and yaw braking solutions, brake pads, yaw discs, hydraulic power units (HPUs) and cooling systems. Its BSAB 90, for example, is a hydraulically applied active yaw brake offering a clamping force of 200,000 N, which will be available for viewing on stand.

Brake pads will also be displayed in a variety of standard and bespoke friction materials. In-house chemists allow the company to formulate application specific recipes tailored to any given environmental conditions. All Svendborg Brakes products and parts are rigorously tested to ensure the highest levels of performance, providing superior quality assurance for turbine OEMs and operators.

A wind power pioneer, Svendborg Brakes supports the full lifecycle of onshore and offshore wind turbines, backed by sales, engineering, manufacturing and servicing facilities located around the world. Its expertise in wind energy is typified by its aftermarket capabilities – whether rapidly responding to breakdowns, training customers so they can increase operational autonomy, or imparting its knowledge and unique tooling to the wider sector.

Regal Rexnord provides the expertise of Svendborg Brakes, Stromag, Centa, Tollok, Juare, Ameridrives and Warner Electric. Together, the brands of Regal Rexnord offer one source support and interoperable solutions, all designed to deliver maximum uptime in renewable power generation.

www.svendborg-brakes.com