www.industryemea.com

19

'16

Written on Modified on

ïndustry 4.0: Hainbuch goes digital and introduces automation and networked manufacturing solutions at the AMB

Hainbuch goes digital - from automatic loading, to unattended machining of a range of different parts and even process control

Hainbuch has a number of intelligent workholding solutions for automation and networked manufacturing up its sleeve. Digital workflow data can now be used to manage process flows and productivity can be increased by performing the appropriate analysis and data processing. Even clamping technology generates data that can contribute to process flow optimisation. For example tooling and maintenance times can be reduced in advance and the machine time can be used for production instead.

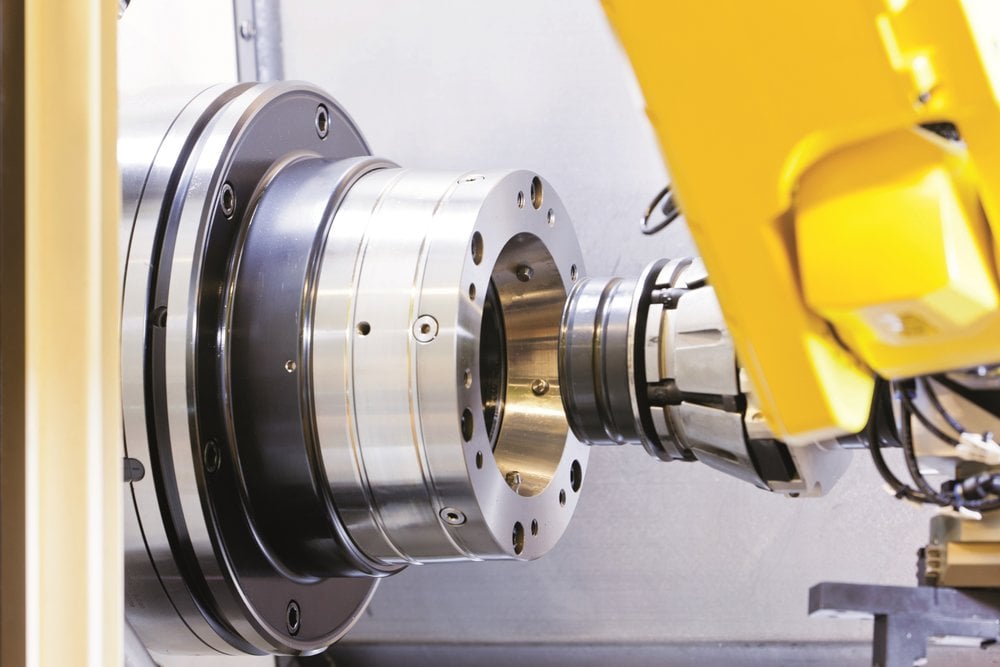

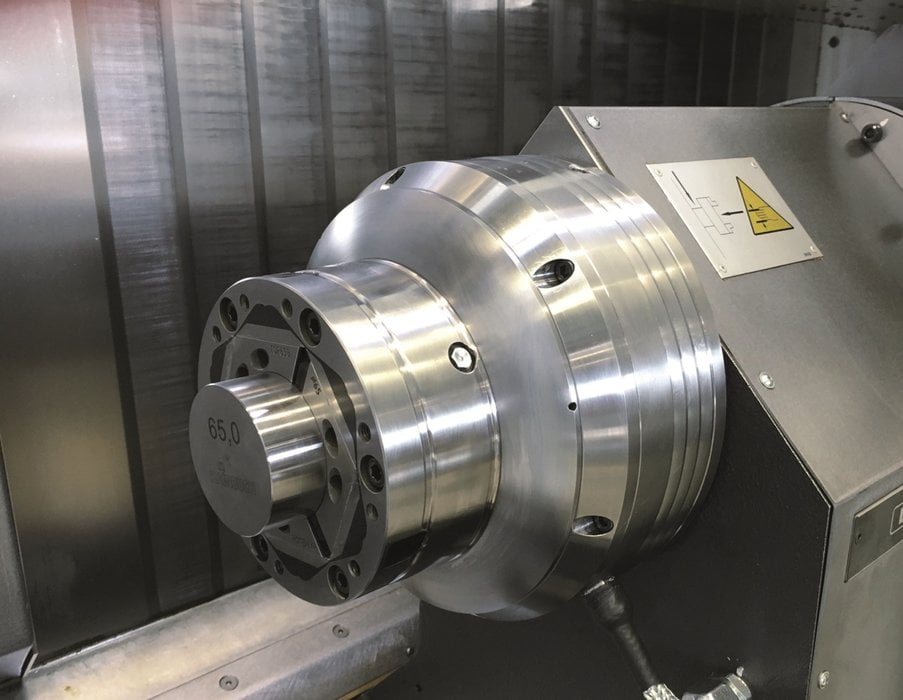

These are not a pipe dream but hard facts; Hainbuch is going to introduce Toplus IQ an intelligent clamping chuck with integrated measurement technology which is able to constantly measure the electronic clamping force and the changes during rotation.

Real-time measurement of the effective clamping force.

By using the optimum clamping force, workpiece deformations and uncontrolled workpiece scrap can be prevented. It is also possible to measure the clamp path with reference to the workpiece tolerances. This measures the diameter of the workpiece and only good parts are processed. The measurement result can also be documented for DIN EN 1550 traceability. A new addition to the Hainbuch product portfolio is the feed force setting gaugefor RS feed clamps.

This measures the feed force electronically and computes the ideal values. The identical settings can be used for multiple feed clamps in multi spindle machines and can be easily documented. Also included in the launch is the popular Testit clamping force gauge for external and internal clamping force and the automatic changeover of clamping heads and workpiece stopper for autonomous tooling and production of pieces with different clamping diameters and feed depths. These solutions from Hainbuch increase machine availability and process capacity as well as reducing upstream and downstream measurement procedures. Quality is also improved or stays at a constantly high level.