www.industryemea.com

26

'16

Written on Modified on

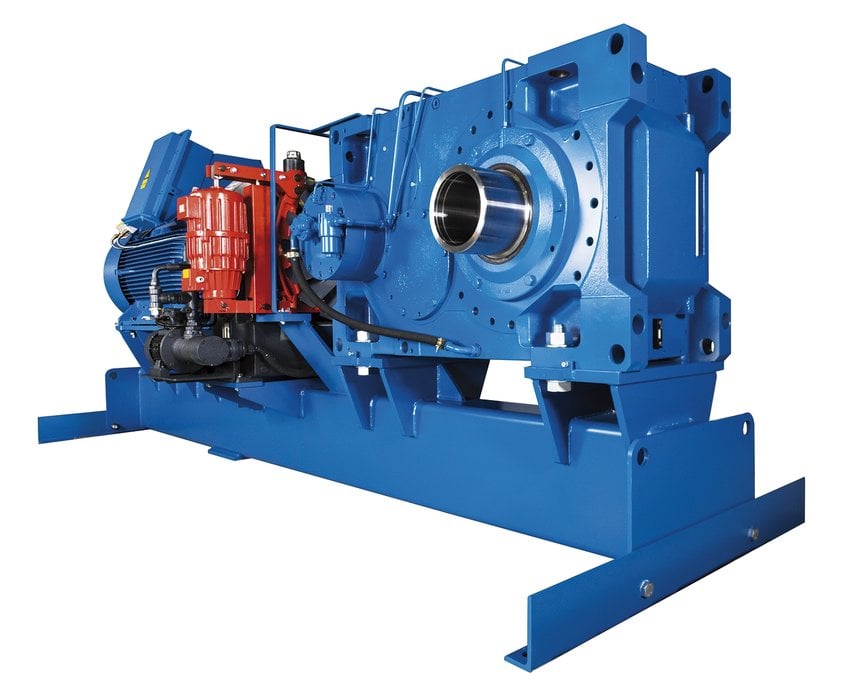

Record-size industrial gear unit in a one-piece housing

NORD DRIVESYSTEMS, a leader in drive technology, has engineered an industrial gear unit with 240,000 Nm rated torque load and various application-specific features for a phosphate mine in Morocco. It is to date the largest system with a one-piece gear case.

(The brake guard and gear inlet have been removed for the purpose of this photo.)

The drive unit comprises an SK 15407 industrial bevel gear unit, a medium-voltage electric motor with a 450 kW performance rating, a swing base, a hydraulic coupling, and an electro-hydraulic brake. It is one of 26 systems NORD designed according to an extremely stringent set of specifications and taking into account the harsh environmental and operating conditions. These units drive a conveyor that is over two kilometers long and carries phosphate ore with loads exceeding several hundred tons. The high-performance gear unit meets the client’s demanding requirements, in particular maximum uptime and high tolerance to peak loads and impacts. The UNICASE gear design prevents leaks and delivers excellent radial and axial load capacities with a small footprint. The industrial gear design unit allows for mounting on all six sides as well as by means of a flange. NORD’s Casablanca office engineered the drive with the assistance of NORD engineers in France and Germany. The components at the inlet of the gear unit are covered by safety guards to protect operators from the rotating parts. The application side, which includes the gear unit, can be fully disconnected from the motor side via the hydraulic coupling. The solution ensures ultra-reliable operation and a high level of safety.