www.industryemea.com

15

'24

Written on Modified on

Cell Impact partners with ANDRITZ for high-volume production of bipolar flow plates

This partnership follows ANDRITZ’s development of the world’s fastest, most productive welding machine for welding one bipolar plate per second (1 Hz), matching the throughput of the Cell Impact forming process.

www.andritz.com

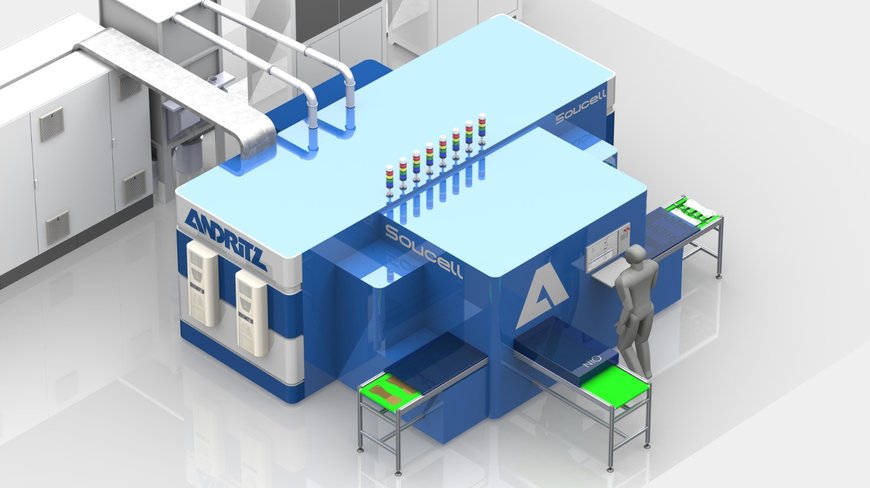

Soucell laser welding machine

Cell Impact has signed a collaboration agreement with international technology group ANDRITZ to advance large-scale, high-speed production of bipolar flow plates for fuel cells and electrolyzers.

Cell Impact of Sweden produces bipolar flow plates using proprietary high-speed forming technology. To boost its production capacity, the company plans to combine its technology with ANDRITZ’s advanced welding process. As part of the collaboration, ANDRITZ will complete the development of its new Soucell system. This multi-scanner (Galvo-Laser), on-the-fly welding system is capable of welding one bipolar plate per second (1 Hz), matching the throughput of the Cell Impact forming process.

The joint project will start in the first quarter of 2025, with the aim of installing a Soucell machine at Cell Impact’s production plant in Karlskoga by the second half of 2026. With the growing demand for bipolar flow plates, the scope of the collaboration is expected to expand.

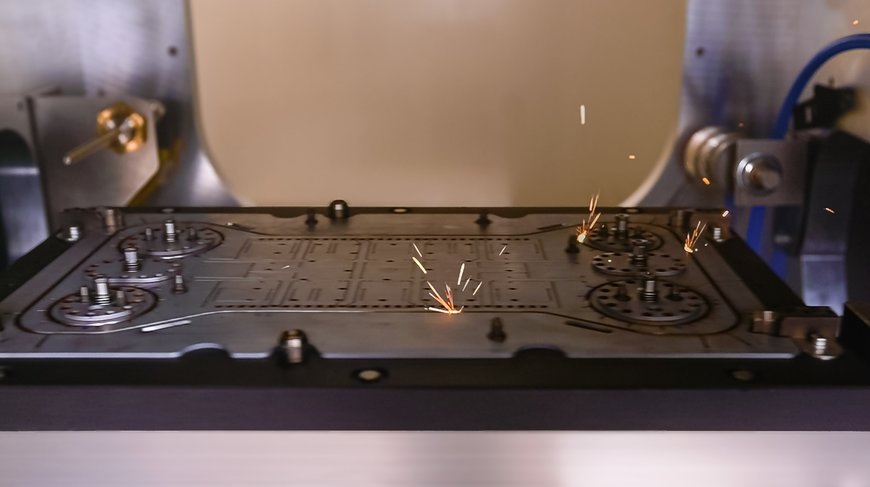

Multi-scanner (Galvo-Laser), on-the-fly welding

www.andritz.com

Cell Impact has signed a collaboration agreement with international technology group ANDRITZ to advance large-scale, high-speed production of bipolar flow plates for fuel cells and electrolyzers.

Cell Impact of Sweden produces bipolar flow plates using proprietary high-speed forming technology. To boost its production capacity, the company plans to combine its technology with ANDRITZ’s advanced welding process. As part of the collaboration, ANDRITZ will complete the development of its new Soucell system. This multi-scanner (Galvo-Laser), on-the-fly welding system is capable of welding one bipolar plate per second (1 Hz), matching the throughput of the Cell Impact forming process.

The joint project will start in the first quarter of 2025, with the aim of installing a Soucell machine at Cell Impact’s production plant in Karlskoga by the second half of 2026. With the growing demand for bipolar flow plates, the scope of the collaboration is expected to expand.

Multi-scanner (Galvo-Laser), on-the-fly welding

www.andritz.com