www.industryemea.com

17

'16

Written on Modified on

Electric Actuators Enable Precise and Highly Dynamic Metering

Mixing and Dosing Directly at the Application Site

Accurate and repeatable dispensing of adhesives and sealants is critical to ensuring design integrity and performance of finished assemblies in industries such as automotive manufacturing, aerospace, renewable energy, electrical and electronics, and the production of white goods. Mixing and dosing of media directly at the application site significantly increases dosing precision and repeatability while reducing cycle times, especially when dispensing multiple small shots from a single metering chamber volume.

German dispensing equipment manufacturer, Hilger u. Kern / Dopag Group, along with their local Curtiss-Wright distributor, Parkem AG, have developed two unique new dispensing systems capable of accommodating low to high viscosity and even abrasive materials. The Vectodis, designed for single component materials, and the Vectomix, designed for multi-component materials, each combine a GSM electric actuator from Curtiss-Wright coupled to a pneumatic discharge valve to provide precise and highly dynamic dosing of a wide range of materials for critical applications.

High process reliability and flexibility is achieved through pressure monitoring in the metering chamber. Reduced dead space avoids material sedimentation and de-airing on the top of the metering chamber eliminates trapped air in the system. Specially guided pistons and drive-to-piston couplings minimize side load, and flushing of the metering piston with sealing liquid when abrasives are used leads to increased reliability and longer life. Metering units with a snuff back effect avoids contamination of the work space..

Single and Multi-Component Media

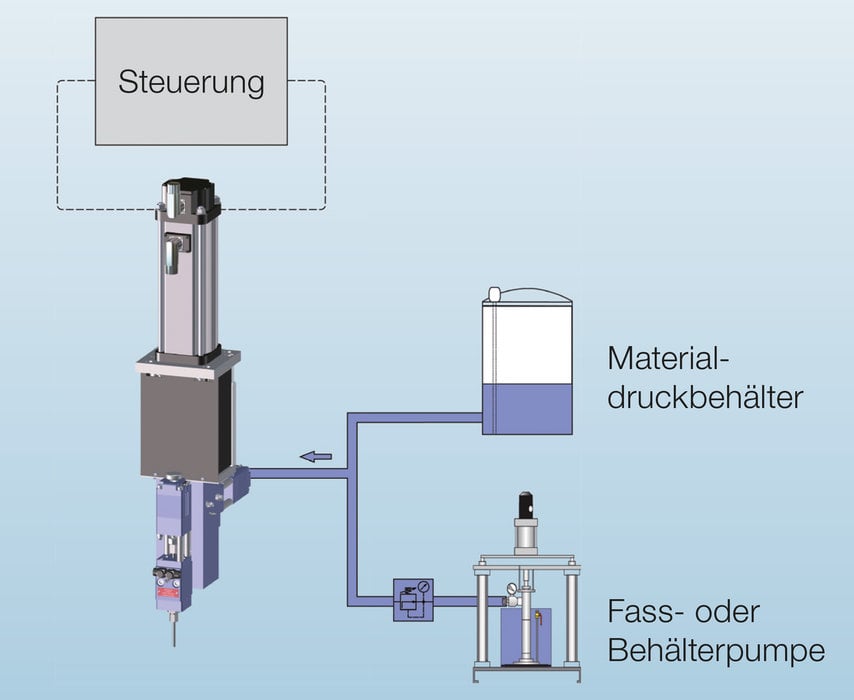

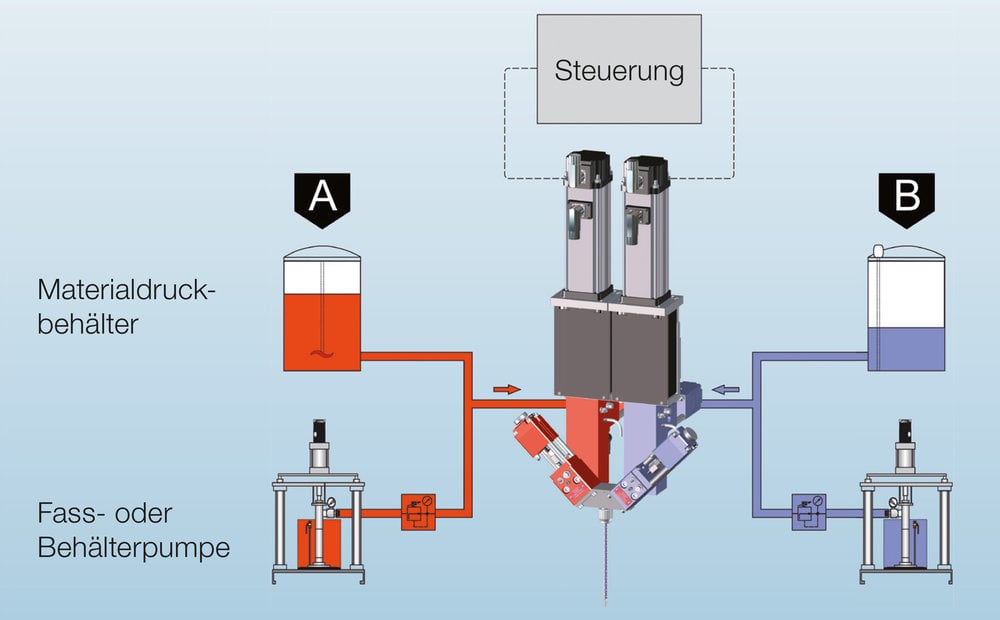

Vectodis (Image 2) is intended for processing single-component media, and material can be applied as either individual dots or a continuous bead. Vectomix (Image 3) is intended for multi-component materials and consists of two synchronized Vectodis systems that independently control the flow rate of each component as it enters the mixing block, located just prior to the plastic mixing tube. Both dispenser systems require an appropriate material supply and metering computer.

Image 2: Vectodis System Image 3: Vectomix System

GSM Electromechanical Actuator

Pneumatic actuators were briefly considered due to their low cost, but were quickly rejected due to their inherently low positional accuracy and lack of dynamic response. Hydraulic actuators were also considered but ultimately were rejected due to concerns over positional accuracy, maintenance requirements, and potential for fluid leaks. Electromechanical actuators offered superior positional accuracy, reduced cycle times, consistent performance over time, and clean and leak-free operation when compared to both pneumatic and hydraulic solutions. Exlar GSM integrated motor/actuators from Curtiss-Wright were ultimately selected due to their compact, power-dense design suitable for use in most industrial environments, including hazardous areas, combining servo motor flexibility and responsiveness with outstanding energy efficiency.

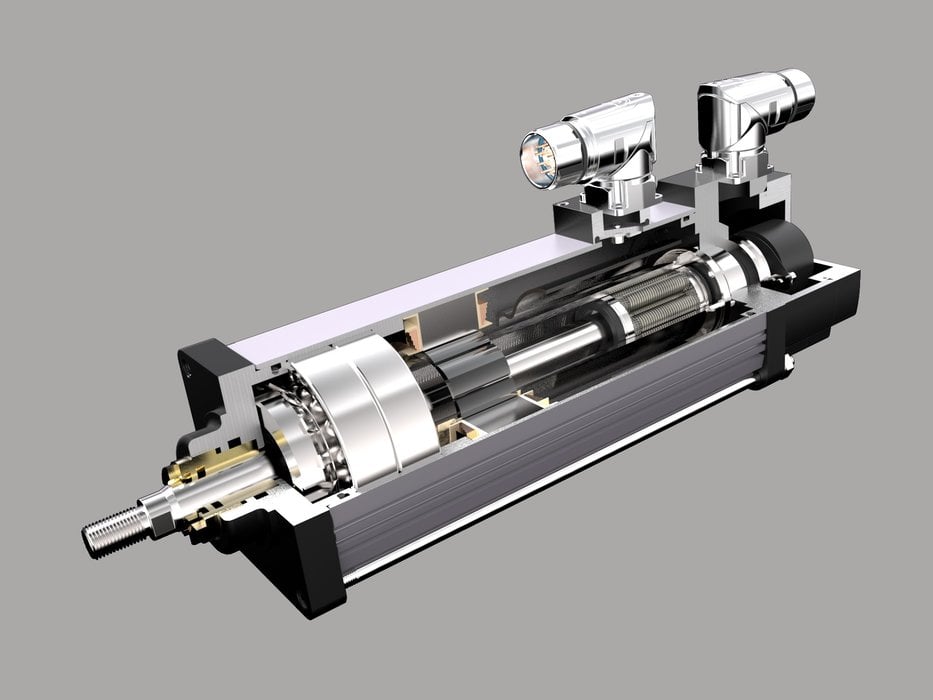

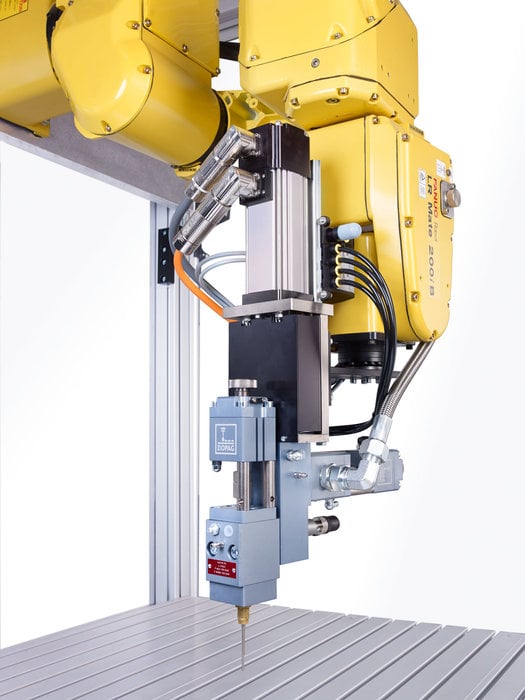

To meet the intended speed, positional accuracy and space constraint requirements Parkem helped size and select Curtiss-Wright’s Exlar GSM electric actuators. The GSM electromechanical actuator (Image 4) integrates an AC servo motor with a planetary roller screw in one compact package. Planetary roller screws provide very high thrust and very long life, while integrating the AC servo motor directly couples the motor to the roller screw for better dynamic performance and reliability. For fully automated robot applications (Image 5) the GSM can be fitted with the robot manufacturer’s feedback device and connectors, ensuring seamless integration with the host robot’s controller as a 7th axis.

Image 4: GSM Electromechanical Actuator from Curtiss-Wright

Control Concept

Each system is controlled by a metering computer with all application parameters accessible through a touchscreen operator interface. The metering computer calculates the required motion of the electric cylinder to achieve the desired material dosing, and allows discharging of material at a rate that is proportional to the speed of travel for robot applications. To achieve intended cost targets while providing the required performance, a Xenus servo controller with CANopen communications was selected.

Image 5: Vectodis System Mounted to a Robotic Arm

Data transmission occurs in real time via the standardized motion control Device-Profile DS402. With the Vectomix system, synchronous transmission of the required data to the two servo controllers occurs simultaneously. The Exlar GSM actuator with integrated encoder operates in closed-loop position mode. Current, velocity and position loops are closed in the Xenus servo controller, simplifying the task of optimizing the individual control loops. Real-time communication and dynamic regulation, coupled with the accuracy of the integrated GSM actuator, results in extremely accurate and reliable dosing.

The advantages over other pneumatic solutions are obvious: closed loop position monitoring and control along with direct coupling of the motor to the actuator provides extremely high dynamic system response leading to precise material deposition. CANopen communication also allows easy access to numerous control parameters for profile adaptation, monitoring and diagnostics. Future product support is available locally or remotely via a TeamViewer remote control application for Windows.

Integrated Solution

Parkem drew on their extensive product offering and engineering expertise to provide optimal selection of the drive components, the design of the GSM electric cylinder and the Xenus servo controller including thermal analysis. The close collaboration between Parkem and Dopag resulted in condensed commissioning time, optimization of the control parameters, and extensive operator training leading to overall performance that exceeded design expectations.

David Hansen, Marketing Manager, Exlar Actuation Solutions, Curtiss-Wright Corporation