ENEMAC Expands Clamping Solutions with Innovative ESG Mechanical Nut

The ESG series delivers up to 12 tonnes of manual clamping force, with a crown gear design ideal for confined spaces and demanding applications.

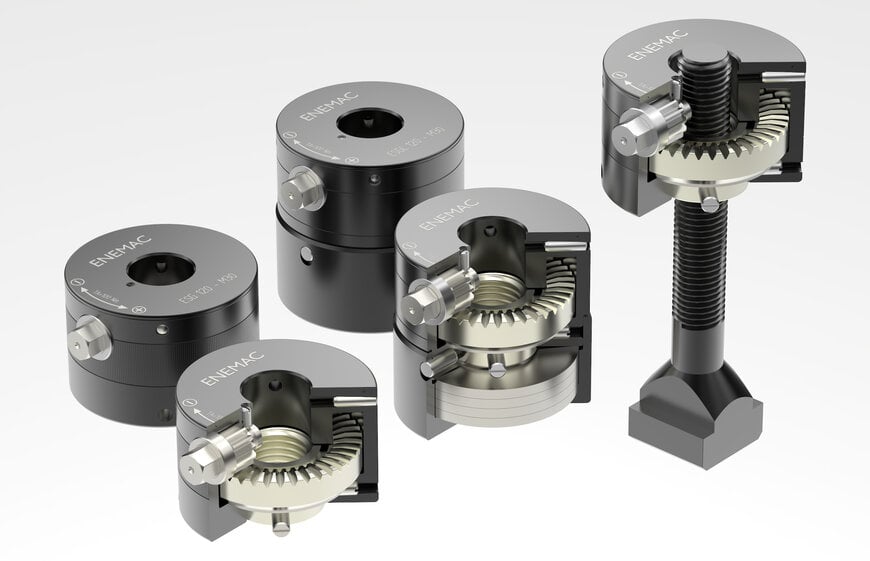

With the ESG series, the clamping technology specialist ENEMAC is expanding its portfolio with a mechanical clamping nut that optimally extends the proven ESB and ESD types. The clamping force is increased by a precise crown gear that deflects the rotational movement at a right angle and enables manual operation from the side. Thanks to this innovative design, the ESG impresses with its particularly low overall height and compact dimensions, making it ideal for applications in confined installation situations.

Efficient clamping technology with optimised force transmission: The ESG clamping nut utilises an internal crown gear for force-enhanced clamping actuation. By turning a nut attached to the side of the housing, the gearbox is activated with minimal effort, allowing the counterpart to be securely and reliably clamped. This concept allows clamping forces of up to 12 tonnes to be generated manually - without additional aids and with a high level of process reliability.

Easy handling for maximum efficiency:

- Screw the ESG clamping nut onto the existing bolt.

- Tighten the operating hexagon positioned on the side with a standard torque spanner to the specified torque.

- The workpiece or tool is self-locking and quickly fixed.

Flexible application for varying workpiece sizes: The ESG series was specially developed for clamping operations with varying component thicknesses. The continuous thread means there is no restriction on the screw-in depth, which guarantees maximum flexibility. Thread sizes from M16 to M30 are available.

Special versions for demanding environments: For applications under extreme conditions, ENEMAC offers special versions of the ESG clamping nut, including a high-temperature version up to 400 °C for use in foundries or metal processing. A version with an integrated disc spring package is also available, which is used for clamping stroke compensation and ensures increased operational reliability, particularly with heavy press tools.

Versatile - for original equipment and retrofitting: The ESG mechanical clamping nuts from ENEMAC offer a high-performance, maintenance-free and safe clamping solution for both original equipment manufacturers and for retrofitting in existing clamping systems.

www.enemac.com