www.industryemea.com

14

'17

Written on Modified on

Brake Technology 4.0

Safety brakes by mayr® power transmission – fit for the future

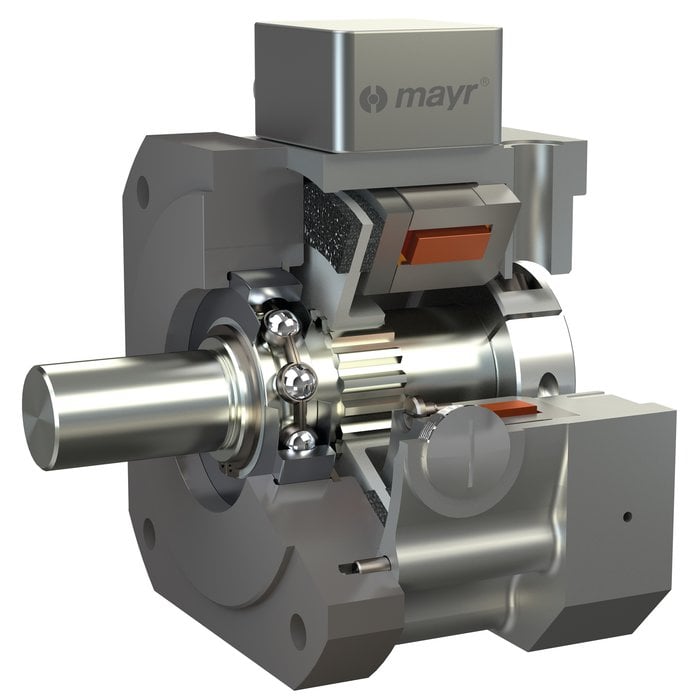

Fig. 1:

Brake technology 4.0 by mayr® power transmission stands for monitoring modules of the latest generation: The modules such as the ROBA®-brake-checker or the ROBA®-torqcontrol allow permanent brake monitoring and make the safety brakes fit for the challenges of the Industry 4.0.

Furthermore, firmly connected with brake technology 4.0 are a technologically leading friction system and consistently considered safety principles. All of this forms the basis for reliable, safe brakes with extremely high performance density.

Image: mayr® power transmission

Monitoring modules of the latest generation, a technologically leading friction system and consistently-observed safety principles – safety brakes by mayr® power transmission are equipped for the challenges of the Industry 4.0. The perfectly-coordinated complete system guarantees the utmost level of operational and functional safety, and increases the productivity of machines and systems through preventative fault detection and maintenance. mayr® power transmission presents its brake technology 4.0 at the Hanover Trade Fair 2017.

With Industry 4.0, the Internet of Things and Services enters companies. That’s why mayr® power transmission as the leading manufacturer is already offering reliable safety brakes, which are equipped for the challenges for the forth industrial revolution. Brake technology 4.0 by mayr® power transmission stands for monitoring modules of the latest generation: The modules such as the ROBA®-brake-checker or the ROBA®-torqcontrol allow permanent brake monitoring. The ROBA®-brake-checker module, for example, monitors the switching condition as well as the tension path or tension force reserve without sensors and detects safety-critical changes in voltage, air gap and temperature. As a result, significantly more processes are depicted during the safety brake monitoring than was previously the case. On reaching the tension path reserve, the ROBA®-brake-checker therefore sends a warning signal indicating that the brake can continue to be operated for a certain amount of time at an early stage. During this time, the machine owner can undertake targeted maintenance – in coordination with their work process. In addition, the module also simultaneously assumes the control of the brake and therefore replaces a rectifier. Switching condition monitoring und brake controls are thus combined in one device.

Braking movements gently and in a controlled manner

For applications, which require braking torque control in addition to status monitoring, mayr® power transmissions provides the braking torque control module ROBA®-torqcontrol. It shares the features of the ROBA®-brake-checker and can also change the level of the braking torque in operation through purposeful influencing of current and voltage. As a result, devices and machines can be evenly and gently decelerated. The ROBA®-torqcontrol module permits the development of control loops and brakes movements intelligently – the ideal basis for its use in smart, interconnected machines.

mayr® friction lining technology – always a step ahead

The developers at mayr® power transmission have successfully created a new friction lining technology through which the brakes achieve even further-improved torque consistency and a higher performance density. Using the new linings, higher braking torques as well as higher area-specific friction work values can be achieved, which means the brakes are of a more compact design, but with the same features. Under certain circumstances, a smaller, lighter brake construction size can be selected for higher braking torques and for brakes, on which higher demands are placed. This takes into account the general trend for machines and their components, for example engines, to be increasingly more compact in construction and with greater performance density.

Brake technology 4.0

Brake technology 4.0 by mayr® power transmission is therefore a comprehensive overall concept, meaning a technologically leading friction system which, together with consistently considered safety principles, stands for reliable, safe brakes with extremely high performance density. Innovative monitoring solutions are firmly integrated into this system, and as a result mayr® brakes and the corresponding monitoring modules are able to master all challenges when safety regulations and standards meet Industry 4.0 and the demand for the depiction of all processes involved. They ensure the utmost operational reliability and enable preventative, purposeful maintenance in the increasingly compact, higher performance density machines and systems.

mayr® power transmission at the Hanover Trade Fair 2017: Hall 25, Stand D30.

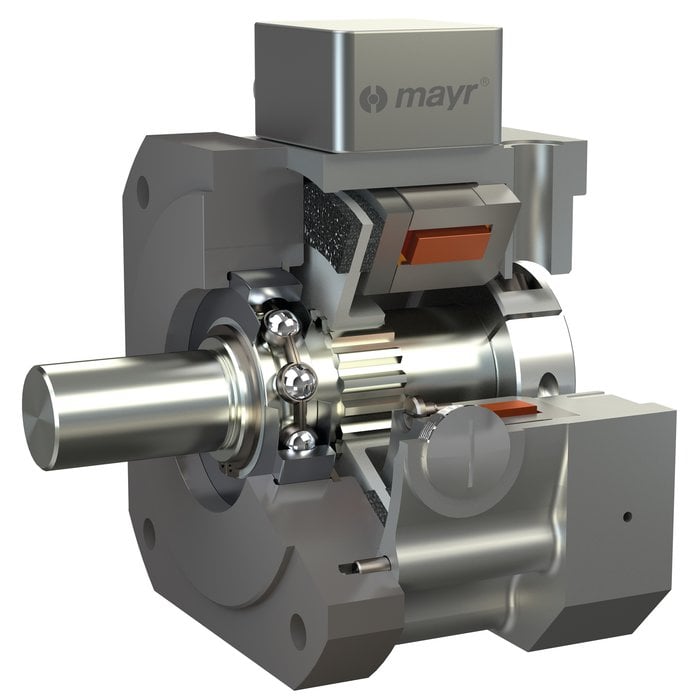

Fig. 2:

The developers at mayr® power transmission have managed to create a new friction lining technology using which the brakes can achieve a further-improved torque constancy and higher performance density. With the new linings, higher braking torques and higher area-specific friction work values can be achieved, which means that brakes can be reduced in size whilst retaining the identical properties. Under certain circumstances, a smaller, lighter brake construction size can be selected for higher braking torques and for brakes, on which higher demands are placed.

Image: mayr® power transmission

Brake technology 4.0 by mayr® power transmission stands for monitoring modules of the latest generation: The modules such as the ROBA®-brake-checker or the ROBA®-torqcontrol allow permanent brake monitoring and make the safety brakes fit for the challenges of the Industry 4.0.

Furthermore, firmly connected with brake technology 4.0 are a technologically leading friction system and consistently considered safety principles. All of this forms the basis for reliable, safe brakes with extremely high performance density.

Image: mayr® power transmission

Monitoring modules of the latest generation, a technologically leading friction system and consistently-observed safety principles – safety brakes by mayr® power transmission are equipped for the challenges of the Industry 4.0. The perfectly-coordinated complete system guarantees the utmost level of operational and functional safety, and increases the productivity of machines and systems through preventative fault detection and maintenance. mayr® power transmission presents its brake technology 4.0 at the Hanover Trade Fair 2017.

With Industry 4.0, the Internet of Things and Services enters companies. That’s why mayr® power transmission as the leading manufacturer is already offering reliable safety brakes, which are equipped for the challenges for the forth industrial revolution. Brake technology 4.0 by mayr® power transmission stands for monitoring modules of the latest generation: The modules such as the ROBA®-brake-checker or the ROBA®-torqcontrol allow permanent brake monitoring. The ROBA®-brake-checker module, for example, monitors the switching condition as well as the tension path or tension force reserve without sensors and detects safety-critical changes in voltage, air gap and temperature. As a result, significantly more processes are depicted during the safety brake monitoring than was previously the case. On reaching the tension path reserve, the ROBA®-brake-checker therefore sends a warning signal indicating that the brake can continue to be operated for a certain amount of time at an early stage. During this time, the machine owner can undertake targeted maintenance – in coordination with their work process. In addition, the module also simultaneously assumes the control of the brake and therefore replaces a rectifier. Switching condition monitoring und brake controls are thus combined in one device.

Braking movements gently and in a controlled manner

For applications, which require braking torque control in addition to status monitoring, mayr® power transmissions provides the braking torque control module ROBA®-torqcontrol. It shares the features of the ROBA®-brake-checker and can also change the level of the braking torque in operation through purposeful influencing of current and voltage. As a result, devices and machines can be evenly and gently decelerated. The ROBA®-torqcontrol module permits the development of control loops and brakes movements intelligently – the ideal basis for its use in smart, interconnected machines.

mayr® friction lining technology – always a step ahead

The developers at mayr® power transmission have successfully created a new friction lining technology through which the brakes achieve even further-improved torque consistency and a higher performance density. Using the new linings, higher braking torques as well as higher area-specific friction work values can be achieved, which means the brakes are of a more compact design, but with the same features. Under certain circumstances, a smaller, lighter brake construction size can be selected for higher braking torques and for brakes, on which higher demands are placed. This takes into account the general trend for machines and their components, for example engines, to be increasingly more compact in construction and with greater performance density.

Brake technology 4.0

Brake technology 4.0 by mayr® power transmission is therefore a comprehensive overall concept, meaning a technologically leading friction system which, together with consistently considered safety principles, stands for reliable, safe brakes with extremely high performance density. Innovative monitoring solutions are firmly integrated into this system, and as a result mayr® brakes and the corresponding monitoring modules are able to master all challenges when safety regulations and standards meet Industry 4.0 and the demand for the depiction of all processes involved. They ensure the utmost operational reliability and enable preventative, purposeful maintenance in the increasingly compact, higher performance density machines and systems.

mayr® power transmission at the Hanover Trade Fair 2017: Hall 25, Stand D30.

Fig. 2:

The developers at mayr® power transmission have managed to create a new friction lining technology using which the brakes can achieve a further-improved torque constancy and higher performance density. With the new linings, higher braking torques and higher area-specific friction work values can be achieved, which means that brakes can be reduced in size whilst retaining the identical properties. Under certain circumstances, a smaller, lighter brake construction size can be selected for higher braking torques and for brakes, on which higher demands are placed.

Image: mayr® power transmission