Rollers and components for intralogistics

As a engineering plastics specialist, faigle supplies high performance components for intralogistics systems. At the ProMat trade fair in Chicago from 03.-06.04.2017, faigle is exhibiting rollers, wheels and other components for conveyors and sorting systems

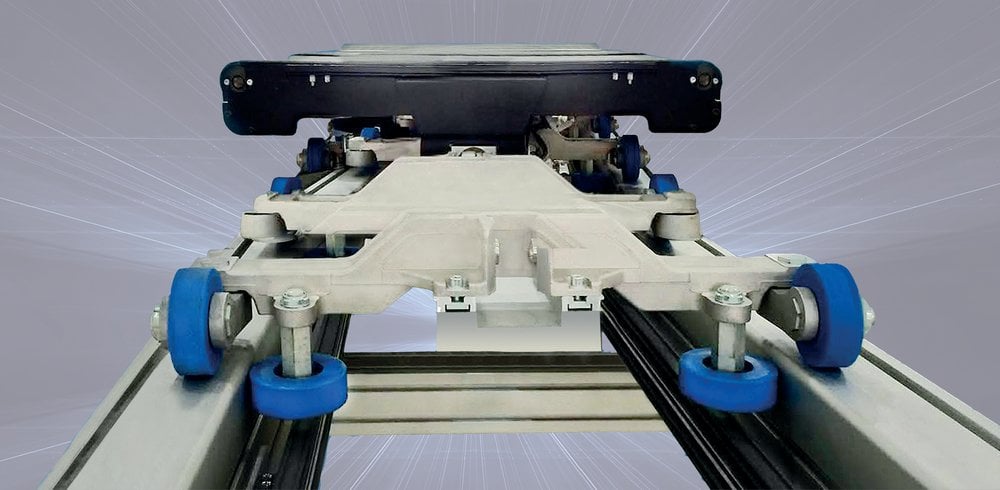

Support- and guiding rollers: Prime movers in intralogistics

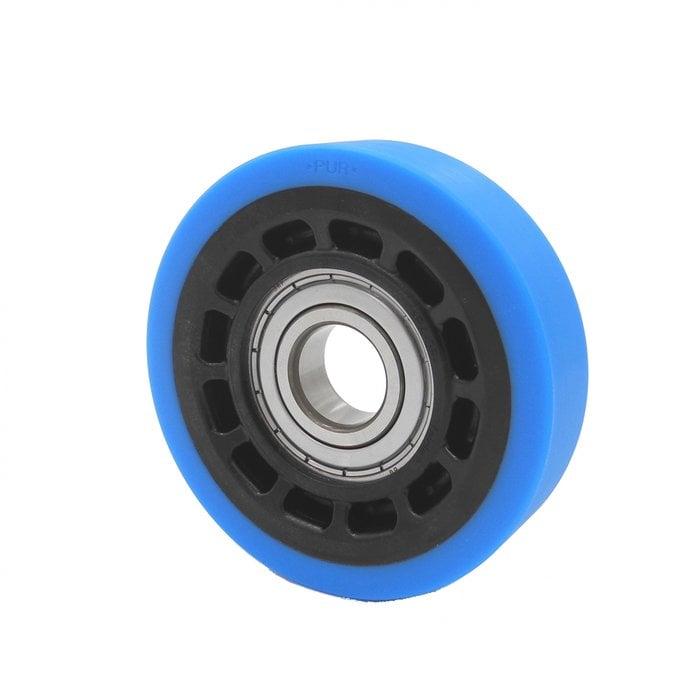

In conveyor and sorting systems, support- and guiding rollers do most of the work. faigle uses PAS®-PU A-H thermoplastic polyurethane for its rollers. This high-performance material, which they developed themselves, is extremely abrasion-resistant and has excellent damping characteristics. Noise and vibrations are reduced, the rollers run very smoothly. In addition the faigle plastic material has an extremely long lifespan. This prevents unnecessary machine stoppages and keeps operating costs low.

To prevent hydrolysis, the decomposition of the polymer materials by water molecules, faigle has developed a hydrolysis-resistant type of polyurethane. Since many years, PAS®-PU A-H has been the standard material for all rollers that the company makes for conveyor systems. Tests have shown that faigle rollers made of PAS®-PU A-H have superior moisture resistance compared to rollers made of cast polyurethane.

faigle rollers have a polyamide-based hub. The material is reinforced with glass fibres for optimum strength, impact resistance and resistance to creep deformation. All faigle rollers are also equipped with high-quality ball bearings. They are manufactured to stringent specifications and tested on faigle's own test benches before they are released.

Broad portfolio: important secondary rollers and other components

The faigle range of rollers for intralogistics also includes diverter rollers and belt deflection rollers. Diverter rollers alter the direction of the flow of goods on the conveyor systems. They are put under enormous stress by high speed, the weight of the goods and a diversion angle of up to 90°.

The hubs of faigle diverter rollers are made of extremely stable carbon fibre reinforced polyamide; the tires are made of elastic and tough thermoplastic polyurethane. The sheet metal ring protects both the rollers and the drive belt from wear.

Belt deflection rollers have a smooth outer surface to prevent abrasion on the drive belt. In addition, they are electrically conductive which prevents the belts becoming electrostatically charged. Shuttle wheels, flaps for shuttle systems and heavy duty chain slide-rails complete the wide range of faigle products for intralogistics. These components are also based on high performance plastics developed internally by the company.

faigle service: Custom components, quality is the benchmark

In addition to their broad range of products, faigle offers customized development: Experienced engineers develop solutions to meet specific customer requirements. All components are made of high performance materials developed by the plastics specialist in their own labs.

Figure 1

faigle support- and guiding rollers are made of extremely abrasion-resistant thermoplastic polyurethane

Figure 2. faigle diverter rollers withstand enormous stresses. A metal steel ring protects the rollers and drive belts from wear.

Figure 3. faigle transforms customer requirements into tailored products and component assemblies. faigle is able to make full use of its extensive specialist know-how and the most modern tools.

Figure 4. Support- and guiding rollers do most of the work in intralogistic systems. faigle rollers meet the tough requirements of fast-moving sorting systems while achieving an excellent price/performance ratio.

As the owner of all unrestricted rights for the above pictures, we grant your magazine the right to use them, subject to acknowledging faigle Kunstoffe GmbH as the source in the framework of the projected article. This also applies to versions of these pictures in printable resolution as well as their print or online use.

We appreciate your forwarding us a copy of the publication for our files.