Live at Fachpack in Nuremberg

Efficient drive solutions from NORD for the packaging industry.

www.nord.com

At Fachpack from 23 to 25 September 2025, system provider NORD DRIVESYSTEMS will present innovative and industry-specific drive solutions for the packaging industry. The experts from Bargteheide look forward to welcoming many visitors in Hall 3C, Stand 440.

At Fachpack, NORD will present a comprehensive portfolio of flexible system solutions, specially tailored to the packaging industry’s requirements. With its modular products, the company meets the various process chain’s requirements – from primary to end-of-line packaging –, supporting an efficient and future-proof machine planning.

NXD tupH® surface treatment

In primary packaging, the new NXD tupH® surface protection from NORD is an economical and effective alternative to stainless steel, paintings or covers. The surface protection is available for all NORD drive components in smooth aluminium housings. The finishing process transforms the upper layer of the aluminium body into a corrosion-resistant base layer. An extreme resistance to acids and alkalis in wash-down areas and a better hardness compared to an untreated aluminium alloy is achieved in combination with a sealer. This prevents flaking or corrosive infiltration and the protective effect will remain unchanged even in case of minor mechanical damage. NXD tupH® surfaces are free from PFAS, and food-safe according to the FDA, the EU Regulation 1935/2004 and the respective regulations in Switzerland and the MERCOSUR states.

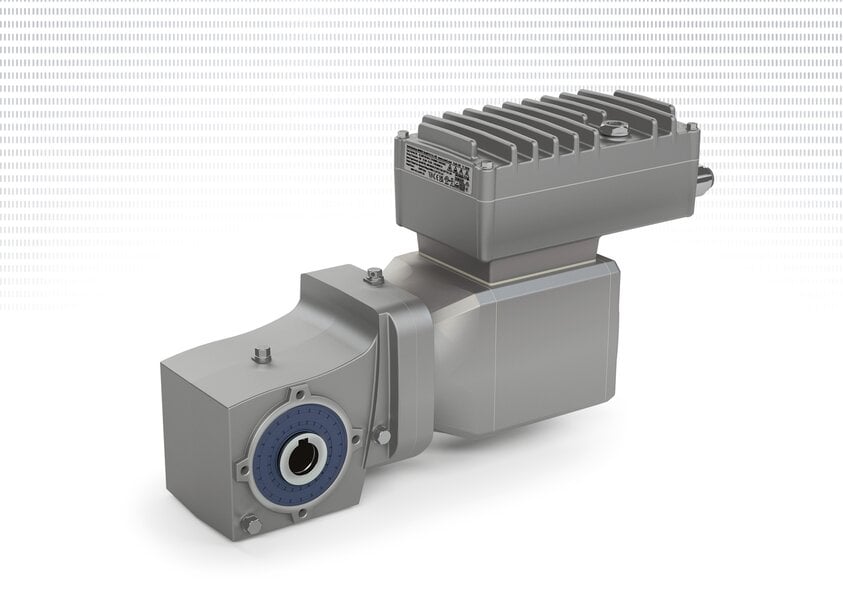

Decentralised drive electronics for end-of-line packaging

In end-of-line-packaging, the manufacturer’s decentralised drive solutions with asynchronous motors provide a streamlined alternative as they shorten installation times, save space in control cabinets and reduce TCO. In the field of feeding and handling packaging machines, for example, the decentralised NORDAC ON/ON+ frequency inverters impress with their compact design and high reliability. They are characterised by PLC functionality for drive-related functions (PLC onboard) and an integrated Ethernet interface. PROFINET, EtherNet/IP and EtherCAT can be set via parameters. With their plug-and-play function, the smart inverters significantly reduce wiring efforts and provide a compact and economical solution for modern production environments.

Thanks to its scalable functions, the NORDAC FLEX SK 200E frequency inverter can be flexibly tailored to various customer requirements. With its extensive digital and analogue inputs and outputs as well as optional In/Out extension, it offers high compatibility with common PLC controls. The inverter also features an expandable Ethernet interface and is compatible with all common higher-level PLC controls and NORD frequency inverters.

Servo adapters for primary and secondary packaging processes

NORD’s servo adapter solutions offer seamless integration for NEMA and IEC flange motors. The adapters enable reliable connections that withstand the demanding conditions in the packaging industry.

Visit us from 23 to 25 September at Fachpack in Hall 3C, Stand 440, and experience future-oriented technology live on site.

Image overview:

NORD-NXD-tupH.jpg: The food-safe NXD tupH® surface treatment makes the surfaces of drives with aluminium housings particularly resistant

Image: NORD DRIVESYSTEMS

NORD-drive-electronics.jpg NORD offers decentralised drive electronics for the packaging industry from a wide range of modular products

Image: NORD DRIVESYSTEMS