Optimizing SMT Lines with Integrated Process Monitoring Software

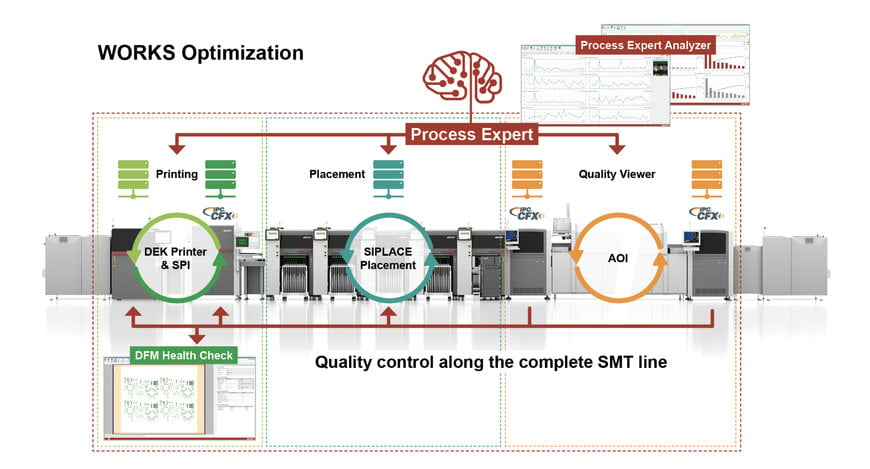

ASMPT’s WORKS Optimization integrates printing, placement, and SPI/AOI data via IPC-2591-CFX, automating process control to reduce scrap and accelerate SMT production.

smt.asmpt.com

WORKS Optimization from technology and market leader ASMPT is a software solution for quality-oriented and integrated process monitoring in SMT manufacturing. It collects and evaluates data from printing and placement processes along the entire line and makes deviations and repeated causes of faults detectable at an early stage. While the printing process can be fully optimized automatically, the software supports the placement process with targeted action recommendations, leading to reduced waste, more stable processes, and significantly faster new product introductions.

“While zero DPMO is what we are always aiming for, it only makes sense when we look at quality and productivity in combination,” says Thomas Bliem, Vice President R&D at ASMPT SMT Solutions. “WORKS Optimization is a software application that focuses on making processes more stable. It ensures reliable printing and placement processes, reduces scrap, and makes existing SMT lines more productive.”

While many inspection systems continue to focus on individual products or stations, WORKS Optimization extends the view to the entire line with its inline Process Expert system. Its three modules – Printing, Placement, and Quality Viewer – retrieve process values from printing and placement systems, along with SPI and AOI data, via the standardized IPC-2591-CFX interface. This cross-product and cross-line view enables faster identification of fault causes – both locally and across the entire process – and allows for precise corrective actions, even for sporadic deviations that might otherwise go unnoticed in daily operations.

The Process Expert Analyzer delivers comprehensive fault statistics through key performance indicators and customizable charts, supporting operating staff in pinpointing sources of problems. Furthermore, reports from WORKS Optimization can be routed to a predefined pool of experts, selected according to their qualifications.

Automated paste printing optimization

In combination with the ASMPT’s Process Lens or a third-party SPI system, WORKS Optimization optimizes the printing process automatically, without any operator assists. If necessary, the system can also trigger offset corrections and cleaning cycle optimizations. The Printing module uses stencil data in combination with the ASMPT process knowledge database to determine all relevant printing parameters, identify critical layout areas, and propose targeted improvement measures before the first board gets printed. It also accelerates new product introductions significantly with the help of so-called ‘fractional experiments’, which use a few test prints to determine the best parameters for a stable printing process.

New: Placement process support

If the line employs SIPLACE placement machines, WORKS Optimization identifies deviations in the placement process and prioritizes appropriate corrective measures. The information appears on the respective machine’s display so that operators see right away where they need to take action. This relieves more qualified specialists and ensures that available resources are used in a targeted and effective manner.

Data integration as the key to process improvements

“More automation does not automatically lead to more productivity,” says Thomas Bliem. “Many factories are still using manufacturing data in isolation. With WORKS Optimization, we are going one step further. By integrating quality-relevant information from different systems end-to-end, we create the basis for more productivity and better yields, less scrap, and more process stability overall.”

www.asmpt.com