www.industryemea.com

31

'25

Written on Modified on

ABB powers Tata Steel UK with stirring and supply

Tata Steel's Port Talbot undergoes a £1.25 billion EAF modernization by 2028, with ABB providing power and stirring technologies for cleaner steelmaking.

global.abb

ABB has won orders to provide electrical power supply management and distribution and electromagnetic stirring at Tata Steel’s Port Talbot Steelworks in the UK. The two project scopes by the global technology leader will help ensure safe, efficient and optimized operations when a new 320-ton capacity electric arc furnace (EAF) starts up in 2028.

The global steelmaker is investing more than £1.25 billion at the Welsh plant, inclusive of £500 million in UK Government support, with focus on the energy transition and decarbonization of its operations. The site will shift to low-emission steel recycling, aiming to cut CO₂ emissions by an estimated 90 percent. Tata Steel UK has the ambition to produce fossil-free steel by 2045 and reduce 30 percent of its CO₂ emissions by 2030.

As it begins its work in support of these objectives, ABB will be responsible for the delivery of electrical power distribution equipment, including high and low-voltage switchgear, power transformers and distribution transformers, connected through a power distribution control system across the facility. This will be central to achieving a fully digitally enabled solution for power management and distribution in line with ABB’s ambitions to drive real progress through leaner, cleaner operations.

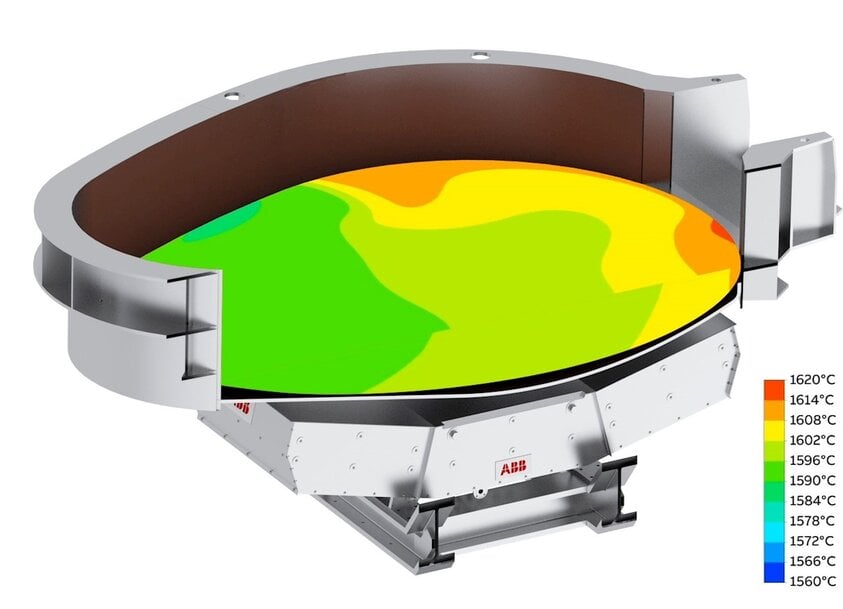

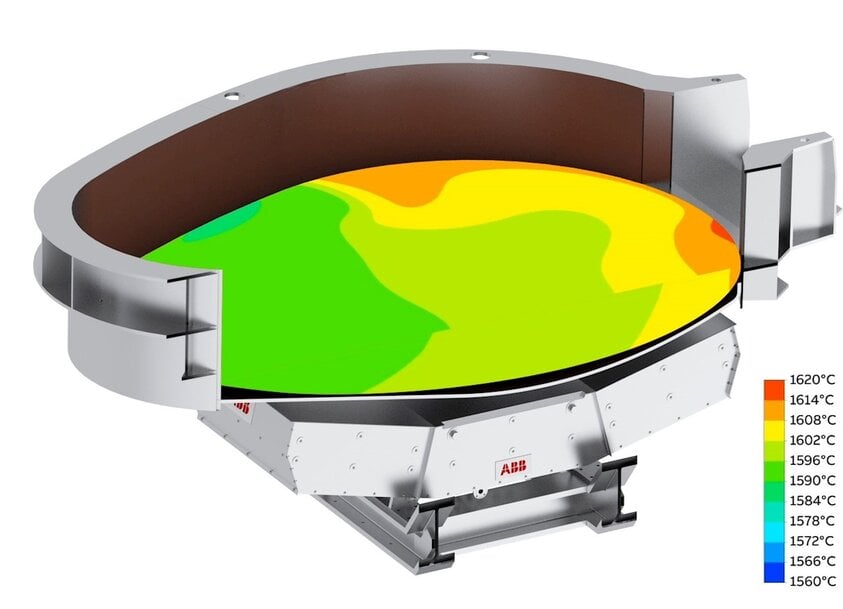

Under the main contract between Tenova, a leading developer and provider of sustainable solutions for the green transition of the metals industry, and Tata Steel, ABB will deliver its ArcSave® electromagnetic stirrer-based metallurgy technology. This equipment, known as Consteerrer® is jointly developed by ABB and Tenova, under an exclusive global partnership agreement, and explicitly tailored for continuous charging EAFs. With over 165 references worldwide, it brings about numerous advantages, including a 5 to 7 percent increase in EAF productivity, a 3 to 5 percent decrease in energy consumption and an additional 1 percent yield.

It is expected that ABB will commission its technologies by 2027 in time for full operational start-up at Port Talbot. Construction work for Tata Steel’s EAF project is set to begin this year. It will mark the start of a significant transformation in the steelmaking process at the site.

ABB provides fully integrated automation, electrification and digitalization solutions to metals plants for higher productivity, quality and availability. Using the latest technology and relying on more than 100 years of industry knowhow, ABB supports metals manufacturers to fulfill their product demands in both greenfield and modernization and upgrade projects.

ABB and Tata Steel have established agreements globally, working together to develop innovative models and ways of working with technologies to reduce the carbon footprint of steel production. As industry partners, they have assessed system-level operations across multiple manufacturing plants and production facilities and evaluated where automation, electrification and digital solutions can be used for short-term and long-term gains, including in energy efficiency, decarbonization and circularity.

www.global.abb

The global steelmaker is investing more than £1.25 billion at the Welsh plant, inclusive of £500 million in UK Government support, with focus on the energy transition and decarbonization of its operations. The site will shift to low-emission steel recycling, aiming to cut CO₂ emissions by an estimated 90 percent. Tata Steel UK has the ambition to produce fossil-free steel by 2045 and reduce 30 percent of its CO₂ emissions by 2030.

As it begins its work in support of these objectives, ABB will be responsible for the delivery of electrical power distribution equipment, including high and low-voltage switchgear, power transformers and distribution transformers, connected through a power distribution control system across the facility. This will be central to achieving a fully digitally enabled solution for power management and distribution in line with ABB’s ambitions to drive real progress through leaner, cleaner operations.

Under the main contract between Tenova, a leading developer and provider of sustainable solutions for the green transition of the metals industry, and Tata Steel, ABB will deliver its ArcSave® electromagnetic stirrer-based metallurgy technology. This equipment, known as Consteerrer® is jointly developed by ABB and Tenova, under an exclusive global partnership agreement, and explicitly tailored for continuous charging EAFs. With over 165 references worldwide, it brings about numerous advantages, including a 5 to 7 percent increase in EAF productivity, a 3 to 5 percent decrease in energy consumption and an additional 1 percent yield.

It is expected that ABB will commission its technologies by 2027 in time for full operational start-up at Port Talbot. Construction work for Tata Steel’s EAF project is set to begin this year. It will mark the start of a significant transformation in the steelmaking process at the site.

ABB provides fully integrated automation, electrification and digitalization solutions to metals plants for higher productivity, quality and availability. Using the latest technology and relying on more than 100 years of industry knowhow, ABB supports metals manufacturers to fulfill their product demands in both greenfield and modernization and upgrade projects.

ABB and Tata Steel have established agreements globally, working together to develop innovative models and ways of working with technologies to reduce the carbon footprint of steel production. As industry partners, they have assessed system-level operations across multiple manufacturing plants and production facilities and evaluated where automation, electrification and digital solutions can be used for short-term and long-term gains, including in energy efficiency, decarbonization and circularity.

www.global.abb