EMCO Mecof Powermill HPC3: Gantry Milling for Large-Scale Precision

EMCO Mecof’s Powermill HPC3 redefines large-scale gantry machining with power, flexibility and digital control for high-production industries.

www.emco-bau.com

A ‘giant’ machine with a technological soul

With axis strokes of 12 metres in X, 4 metres in Y and 2.5 metres in Z, the Powermill HPC3 offers exceptional working capacity. Its portal architecture combined with the box-in-box design ensures rigidity

and thermal stability even in the most demanding machining operations, while the latest generation Siemens Sinumerik ONE numerical control guarantees optimal cycle management and digital integration of production processes.

Flexibility guaranteed by the interchangeable head system

As with other models on display at the Mecof 2025 Open Days, one of the strengths of this machine is its ability to manage different interchangeable heads, all designed for automatic changeover.

The universal bi-rotary head with automatic millesimal positioning offers power (38 kW), torque (1000Nm) and speed (6000 rpm) ideal for complex machining operations, while the more compact vertical spindle head meets the need for precision and versatility. Its dimensions are Ø min. 185 mm, total L 765mm. It offers 15 kW of power, 390 Nm of torque and a speed of 3000 rpm.

Both heads have an ISO 50 connection.

The machine is equipped with automatic parking cradles for the heads, anti-rotation devices, and an Alberti head with ISO 40 connection, internal cooling and 1:1 direct transmission, designed for light machining.

Tool change and measuring systems

Productivity is ensured by a 64-position tool magazine (2 chains of 32 positions), integrated into the shoulder of the machine, with independent chains to maximise changeover speed. There is also a complete measurement and control system, which includes a Renishaw radio probe, kinematic measurement, and tools for checking tool length and diameter.

The importance of cooling

Intensive milling requires effective cooling. For this reason, the Powermill HPC3 destined for China is equipped with a dual cooling system, both external and internal to the spindle (up to 40 bar), 2000-litre collection and filtering tanks, and flow control devices. This solution ensures thermal stability, long tool life and consistent quality of machined parts.

Ergonomics and wireless control

Another detail that should not be overlooked is the possibility for the operator to have safety and freedom of movement during the set-up and control phases. This is possible thanks to the Siemens HBG 800- DP wireless keypad.

Mecof's Powermill HPC3 is not simply a gantry milling machine: it is a complete, ‘giant’ work platform that combines the solidity of traditional mechanics with the intelligence of the most advanced automation.

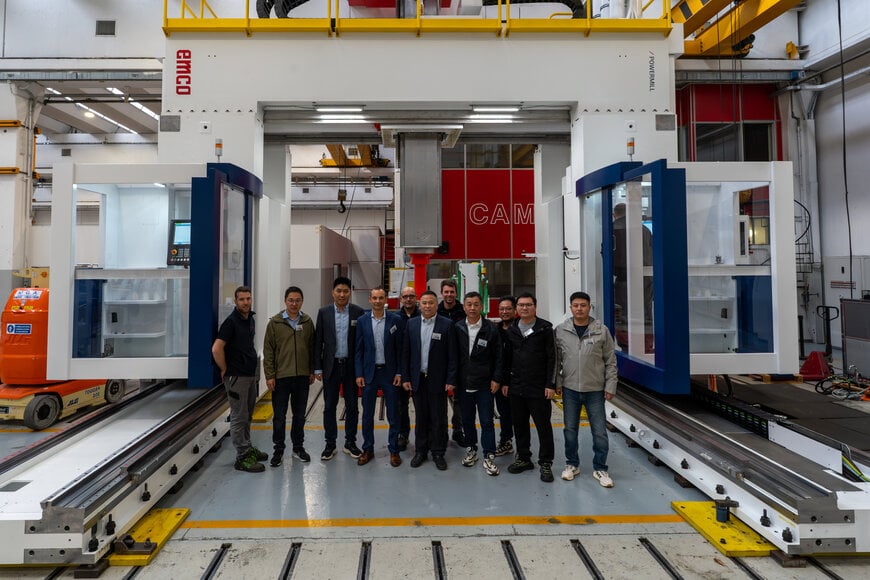

POWERMILL HPC3 present at Mecof Open Days 2025

EQUIPMENT:

Powermill HPC3

CNC Siemens Sinumerik ONE

Travel in X 12.000 mm

Travel in Y 4.000 mm

Travel in Z 2.500 mm

Universal bi-rotary head with automatic millesimal positioning 38 kW, 1000 Nm, 6000 rpm,

ISO 50 tool connection. Designed for automatic head change operations.

Head with vertical spindle, min. external Ø 600 mm, total length 765 mm, 158 kW, 390 Nm, 3000 rpm, ISO 50 tool connection. Designed for automatic head change operations.

No. 2 support for automatic head change, consisting of a cradle with head protection. Precise

references and micro-sensors for automatic stroke limitation are mounted on the work surface

or foundation. The support can be quickly removed from its position.

64-position tool changer located in the shoulder of the machine. Consisting of 2 overlapping

chains with a capacity of 32 positions, equipped with a translation stroke.

Stop block: anti-rotation device for angular heads

Alberti head for light machining, ISO 40 tool attachment, with internal coolant, 1:1transmission ratio, applicable in tool changer.

Renishaw RMP60 radio measurement probe

Kinematic measurement

Device for measuring tool length and diameter, divided into two parts (transmitter and receiver), installed on one of the two crossbeam shoulders, one on the right and the other on the left. Control tool included.

Dual cooling system: 1) delivery near the spindle (pressure 6 bar, flow rate 28 l/min) via manifolds and rigid adjustable nozzles; 2) supply through the spindle (pressure 40 bar, flowrate 20 l/min) via a hole coaxial with the spindle for use with tool holders with a central hole (tools according to DIN 69871/A

2000 l filter tank

2000 l collection tank

Coolant flow rate adjustment

Siemens wireless remote control panel, model HBG 800-DP. As an alternative to the remote control panel provided in the machine base.