SVS-Vistek Vision System Ensures Zero-Defect Engine Fan Production

SVS-Vistek and Vision On Line deploy a 20 MP brightfield vision system to inspect large engine fans with automated tolerance verification for zero-defect production.

www.svs-vistek.com

Engine cooling fan failure in commercial vehicle applications can result in power unit overheating and catastrophic engine damage. To mitigate these risks, a leading manufacturer of engine components has deployed an advanced machine vision system based on SVS-Vistek cameras to enforce zero-defect quality standards. The system has been in operation since 2024.

The manufacturer, a tier-one supplier to multiple OEMs, specializes in thermal management systems for heavy-duty applications including Class 8 trucks, construction equipment, and commercial vehicles. Their cooling fan assemblies represent critical components in engine thermal regulation where failure modes carry significant downstream cost implications.

Vision On Line GmbH, a specialist in machine vision and robot technology in Langenselbold, Germany, was hired to plan, integrate and commission the solution. Vision On Line embedded the systems directly into the production line at four balancing stations, creating a synchronized inspection and data feedback loop with the manufacturer's central control infrastructure.

“The company aimed to increase the level of automation in its production process and ensure that only flawless fans would be delivered to customers for later installation in engines to avoid consequential costs in the event of a defect,” recalls Andreas Schaarschmidt, Managing Director of Vision On Line. “To implement the required vision systems, they were looking for an experienced partner. We had already successfully supported the company in previous projects, so we were very familiar with their processes.”

The implementation presented substantial technical challenges: the manufacturer operated without automated fan inspection capabilities, while the product geometry—with diameters reaching 800 millimeters—demanded a vision system configuration capable of capturing exceptionally large fields of view without compromising measurement precision.

“The required precision could only be achieved by selecting a large brightfield illumination from Büchner and a high-resolution 20 MP camera from SVS-Vistek, combined with matching optics from OPT,” explains Schaarschmidt. According to him, image evaluation is performed using the Halcon software library from MVTec.

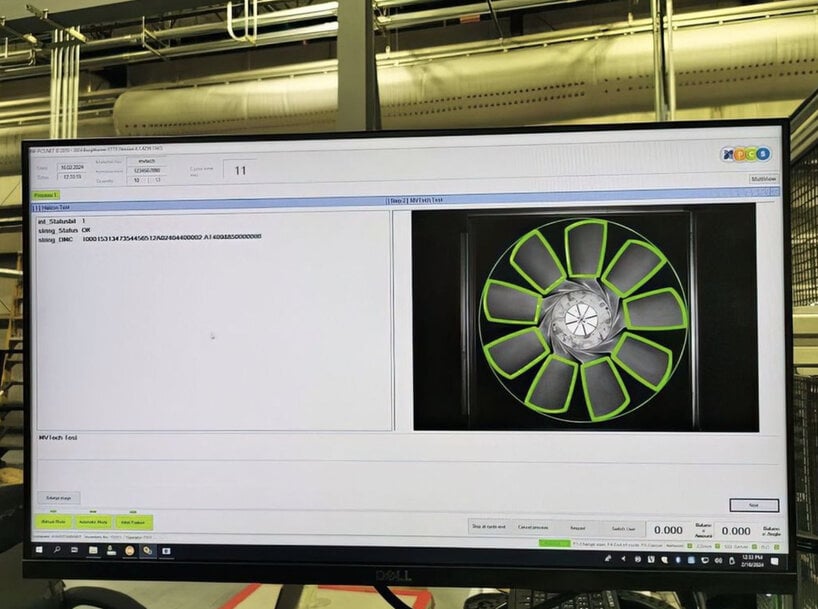

The machine vision systems first read a data matrix code located in the central black area of the fans and then inspect the geometric features of the component (click on image to download, courtesy of Vision On Line)

IMAGE ACQUISITION AND LIGHTING

The SVS-Vistek Exo183MGE camera serves as the primary image acquisition device, selected based on Vision On Line's established integration history with the German manufacturer's Gilching production facility, ensuring supply chain reliability.

The Exo183MGE's 20-megapixel sensor captures full-frame images at 120 MB/s via GigE Vision protocol, while its integrated 4-channel strobe controller provides microsecond-level LED synchronization. This embedded timing architecture eliminates external controller hardware, reducing both system complexity and bill-of-materials costs while maintaining precise illumination-acquisition coordination required for high-speed inline inspection.

Illumination proved critical to system performance. Vision On Line specified a customized Büchner Lichtsysteme TLS-series brightfield array light, engineered with 3,500 blue LEDs across a 600 x 600 mm active area, delivering 177W optical output. The platform's modular design supports configurations up to 2,000 x 3,000 mm in 20 mm increments, accommodating direct or diffuse illumination modes across blue, green, red, white, and infrared spectra, with provisions for multiple camera apertures.

The system detects material anomalies, such as overmolding or material voids, with a measurement tolerance of ±1.0 mm (click on image to download, courtesy of Vision On Line)

SYSTEM OPERATION

Upon placement, the vision system initiates fan inspection by acquiring the data matrix code located on the black-painted metallic hub component. This 2D barcode contains model-specific parameters that the vision system decodes and transmits to the manufacturer's PC-based supervisory control platform, which responds by retrieving the corresponding tolerance specifications and target values for that particular fan assembly variant.

The system then executes a comprehensive geometric validation protocol. Primary inspection criteria include blade count verification and dimensional analysis of individual blade geometries. Critical to fan performance characteristics, the vision system detects material anomalies—including flash from overmolding and material voids—with a measurement tolerance of ±1.0 mm, ensuring that even minor manufacturing defects are flagged before balancing operations.

Measurement data undergoes real-time comparison against the retrieved target parameters. Components meeting all specifications advance to static balancing procedures before shipment to OEM customers for engine integration. Non-conforming units trigger automated rejection, with disposition routing based on defect classification: marginal deviations are directed to rework operations, while out-of-specification components are scrapped to maintain quality integrity throughout the supply chain.

www.svs-vistek.com