STATS Group’s SureTap Plug sets a new safety benchmark for hot tapping completion

Dual-seal completion technology delivers verified Double Block and Bleed isolation in the field.

www.statsgroup.com

In hot tapping and line stopping operations, achieving verified isolation at every stage is critical to protecting personnel and assets. While operators routinely establish fully tested Double Block and Bleed (DBB) isolation during cutting and stopping activities, the final completion stage has historically relied on single-seal plugs that cannot be independently tested before temporary valves are removed—creating a well-known safety gap.

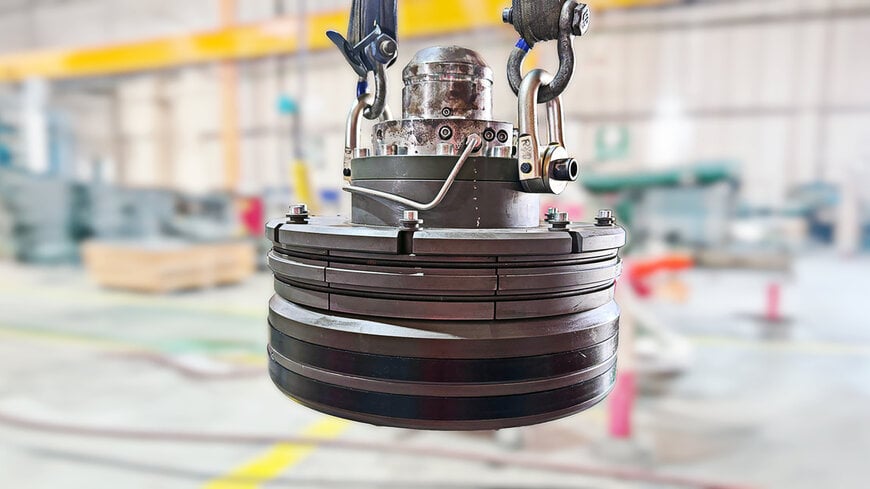

To address this long-standing challenge, STATS Group has engineered the SureTap™ Plug, a dual-seal completion plug designed to maintain DBB isolation through the entire hot tapping workflow, including completion. The technology enables operators to verify seal integrity and confirm correct plug positioning before exposing personnel or demobilising equipment.

Application-driven design for real-world operations

The SureTap Plug introduces two independent compression seals with a testable intermediate annulus, allowing full DBB verification at completion—something not possible with conventional single O-ring designs. This approach directly addresses the risk of misalignment or unverified sealing that has contributed to incidents across the pipeline industry.

Hydraulically actuated with multiple mechanical fail-safes, the plug requires internal lock segments to fully engage a machined groove in the completion flange before seals can activate. A compression prevention plate ensures sealing cannot occur unless correct positioning is achieved. As a result, differential pressure across the plug cannot be applied unless all safety mechanisms are properly engaged and verified.

Operational benefits in the field

Beyond enhanced safety, the SureTap Plug delivers practical advantages during deployment:

- Improved sealing performance through increased surface contact, maintaining isolation even on imperfect flange IDs damaged during hot tapping

- Reduced operational complexity, with a smaller diameter that allows flow around the plug during deployment, removing the need for bypass check valves

- Earlier demobilisation of hot tap machines using an optional hydraulic launcher, cutting equipment hire time and costs

- Broad compatibility, working with standard hot tap machines without proprietary procedures or special licensing

The design meets IMCA DBB requirements for subsea diver safety and is suitable for hydrocarbons, hydrogen, and high-pressure liquid CO₂ systems. With a minimum 25-year design life, it can also be used for permanent abandonment on aging assets.

Raising the standard for completion safety

By extending verified DBB isolation to the completion stage, the SureTap Plug aligns the final step of hot tapping with the same safety standards applied throughout the rest of the operation. Drawing on the proven principles behind STATS’ Tecno Plug® and BISEP® technologies, the solution represents a shift from assumption-based completion to testable, confirmed isolation—helping operators reduce risk while improving efficiency across hot tapping projects.

www.statsgroup.com