www.industryemea.com

20

'26

Written on Modified on

Toyota Motor Europe Invests in Circular Factory in Poland

New 25,000 m² facility in Walbrzych will process 20,000 end-of-life vehicles annually, expanding Toyota’s circular economy operations in Europe.

www.toyota.com

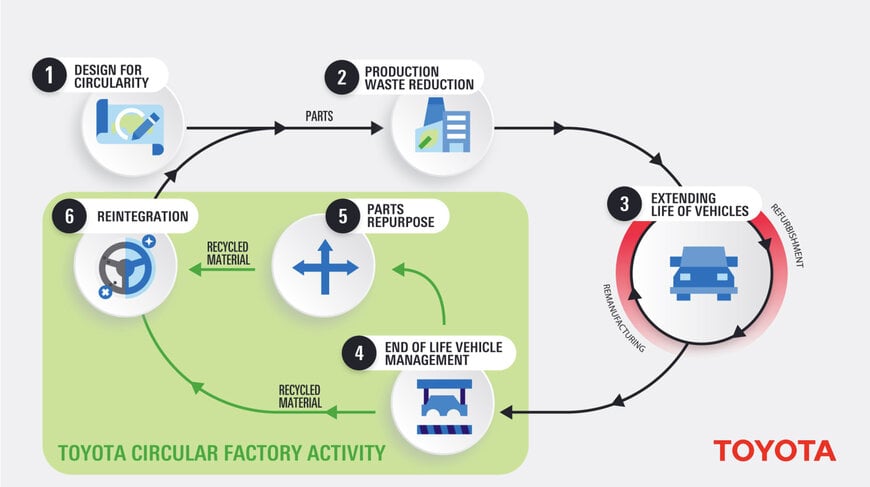

Toyota Motor Europe (TME) has announced a new investment in a Circular Factory in Walbrzych, Poland. The 25,000-square-metre facility will process approximately 20,000 end-of-life (ELV) vehicles per year, supporting the company’s strategy to advance a circular economy model based on reduce, reuse and recycle principles.

Processing and Material Recovery Strategy

The new site will implement a structured approach to vehicle dismantling and material recovery. Components with remaining service life will be assessed for reuse, remanufacturing or repurposing. Parts such as batteries and wheels will undergo technical evaluation to determine whether they can re-enter the value chain.

In addition, the factory will recover raw materials including copper, steel, aluminium and plastics. These materials are intended to be reintegrated into the production of new vehicles, reducing the need for primary raw material extraction.

Expansion of the Walbrzych Manufacturing Hub

The Circular Factory will complement the existing Walbrzych plant, which already manufactures components for hybrid and conventional powertrains. By integrating end-of-life vehicle processing into an established manufacturing site, Toyota strengthens the link between production and material recovery within the same industrial ecosystem.

Second Circular Factory in Europe

According to Leon van der Merwe, Vice President of Circular Economy at Toyota Motor Europe, the Polish site follows the company’s first Circular Factory launched in 2025 in Burnaston, United Kingdom. The UK facility serves as a benchmark for developing circular economy operations across Europe.

Poland was selected due to its market potential for sourcing end-of-life vehicles, its recycling infrastructure, and the presence of Toyota’s existing manufacturing operations. Further similar investments in other European markets are planned in the coming years.

Circularity and Carbon Neutrality

Circular manufacturing models reduce demand for carbon-intensive raw materials and help secure supply chains. By designing vehicles with reuse, remanufacturing and recycling in mind, manufacturers can lower emissions across the entire value chain.

The new investment in Walbrzych represents a practical step toward integrating circular processes into automotive production at industrial scale.

www.toyota.co.uk