Detecting risky residual currents using differential current measurement: operating electrical systems safely with RC monitoring

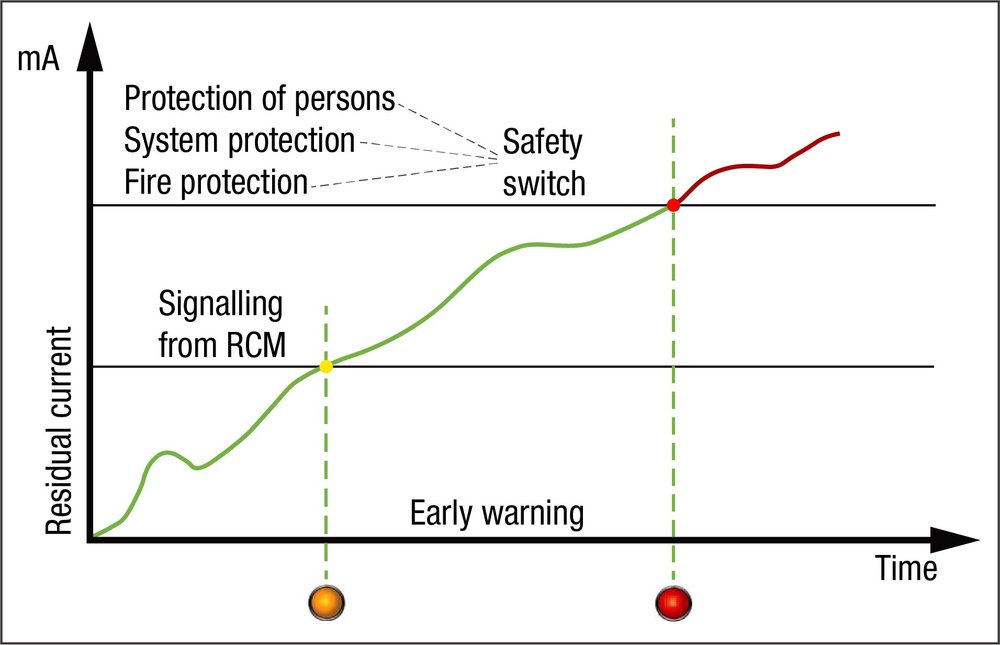

Residual currents in low voltage networks represent a fundamental safety risk, if they go undetected or if they are detected too late. They may cause operations to be interrupted unexpectedly, incurring damage to man and machine and in the final instance, leading to high costs. "Detect early, warn and take action" are the watchwords in risk prevention. Permanent monitoring of residual currents is essential and is used to detect deterioration in the distribution system's insulation in a timely manner.

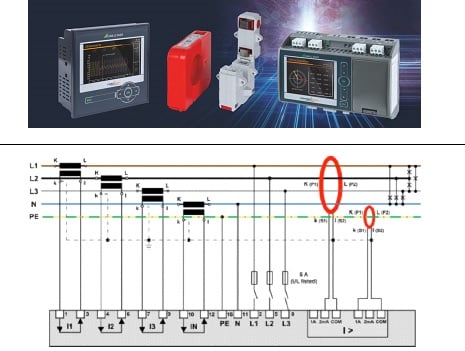

Photo: In the optimum case, six current channels are used for monitoring, as shown here. Channel 5 is used for RCM and Channel 6 is used to directly measure the earth current (up to max. 1,000A).

Photo: The residual current module lowers the safety risk in electrical installations in low voltage networks and provides an early warning when gradual deviations occur.

Measurement of residual currents is performed by residual current transformers. To provide this function, Camille Bauer Metrawatt AG has included residual current transformers to its product portfolio, in bushing-type and split-core versions. An individual alarm threshold and early warning threshold can be defined for each residual current channel. When the alarm threshold is violated, or if the measurement (RCM) conductor is broken, this activates the device's group alarm. Additionally, in devices with a data logger, all status changes are logged in the alarm log and early warning threshold violations are recorded in an event list. The alarm signal can be routed to digital outputs and displayed by the SMARTCOLLECT database software. The residual current values that are currently being measured can be visualised directly on the device display or on the device website (WebGUI) and can also be output on analogue outputs. The values can also be read via bus interfaces.

By recording the average value of the residual current, it is possible to detect a gradual change in the residual current.

The advantages of permanent residual current monitoring are evident. On the one hand, it can eliminate costly periodic manual inspections, which only indicate the status quo at the time of measurement. On the other hand, continuous monitoring improves fire protection and also makes a significant contribution to protection against personal injury and damage to property. Applications for RCM, which is often in used in an energy metering and network quality analysis context, are frequently to be found in data centres, hospitals, hotels and other public buildings (for example shopping centres, airports, etc.), industrial installations, sensitive production units, banks etc. In such cases, to avoid any safety risk, threshold values in compliance with EN 62020 are applied (for example 100 mA).

More information available from www.camillebauer.com