GE and Uniper Unveil ‘GT26 HE’ Solution, the World’s First High-Efficiency Upgrade for the GT26 Gas Turbine Fleet

By Tapping into GE’s H-Class, F-Class and Additive Manufacturing Technologies, GE Unleashes Full Performance of the GT26 Platform.

- GE’s GT26 High-Efficiency Upgrade Provides a Leap Forward in Efficiency; Significantly Decreases Fuel Costs, Increases Plant Output up to 55 Megawatts per Unit and Extends Maintenance Intervals by up to Two Years

- First F-Class Gas Turbine GE Will Upgrade to H-Class Performance Levels at Greater than 60 Percent Combined-Cycle Efficiency

- Uniper’s Enfield Power Plant Will Be the First Site to Install the New GT26 HE Technology in 2020

Continuing its commitment to invest in its mature gas turbine fleets to keep them competitive in today’s dynamic energy marketplace, GE (NYSE: GE) today announced the launch order for its new GT26 HE (high efficiency) gas turbine upgrade with Uniper for the utility’s Enfield Power Station in greater London.

“We’re proud to launch our new GT26 HE upgrade with Uniper—it’s the most advanced solution we’ve ever introduced on a GT26 gas turbine, and one of our most efficient upgrades within the F-class portfolio,” said Scott Strazik, president and CEO of GE’s new Gas Power business. “Not only will this upgrade revitalize Uniper’s Enfield power plant, it will also improve its competitive position in the Great Britain generation market, supporting its long-term profitability and viability.”

The GT26 HE upgrade also marks other GE firsts:

- First upgrade that takes the best technologies and capabilities from GE’s industry-leading F and H class fleets to create a robust solution for GT26 power plant operators.

- First upgrade that blends both GE and Alstom’s technology and expertise across all major components of a gas turbine solution.

Key performance benefits[1] include:

- Higher efficiency for combined-cycle power plants:

- 2+ percent base load increased efficiency, translating to as much as $4 million in fuel savings annually per unit.

- Up to 1 percent increased efficiency in part load, yielding up to $1 million in fuel savings a year per unit.

- Increased plant output from 15 megawatts (MW) up to 55 MWs per unit, improving revenue opportunities.

- Extended inspection intervals up to 32,000 hours, reducing long-term maintenance costs.

Helping Revitalize Uniper’s Enfield Power Station

Uniper’s Enfield power plant in London will be the first site to install the new GT26 HE technology in 2020 with several significant benefits that GE expects to exceed. These benefits will include increased megawatt output, improved plant and gas turbine efficiency, and extended maintenance intervals and operating hours to enable Enfield to consistently elevate its position on the dispatch curve in the highly competitive U.K. power market and ramp up its annual operating hours.

“We’re very pleased to be working with GE on this new technology upgrade,” said Eckhardt Rümmler, chief operating officer, Uniper SE. “In Great Britain’s very competitive and challenging power generation environment, investing to keep our plants competitive by lowering operational and maintenance costs at the same time as increasing efficiency and flexibility is critical for the long-term success of our fleet.”

“The opportunity to test GE’s pioneering GT26 HE upgrade at our Enfield plant, combined with our longstanding relationship with GE and trust in its technology and services were key reasons we chose the company for this project,” added Mike Lockett, chief commercial officer, power, for the Uniper Group and Uniper U.K. country chairman.

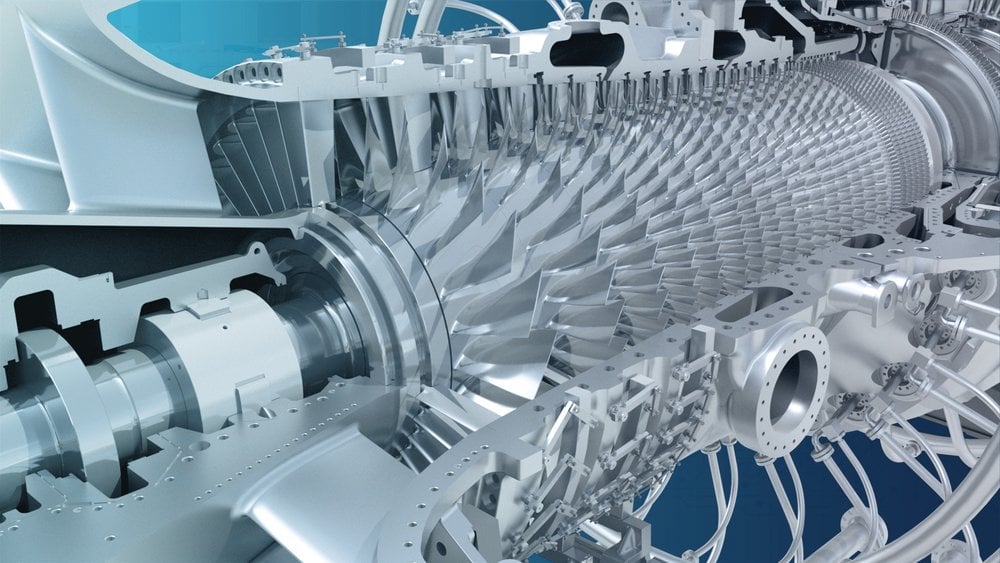

H-Class Technology Infusion Drives High-Efficiency Performance

The GT26 HE upgrade provides a leap forward in efficiency, output and maintenance interval extensions. It’s powered partly through advanced technology from GE’s flagship HA gas turbine, the largest and most efficient in the industry, with additive manufactured parts and innovations in aerodynamics, material science and combustion dynamics. It embeds technology breakthroughs across every major component of the GT26 frame—turbine, compressor and combustor—to take turbine performance to a new level, significantly decreasing fuel costs while increasing full-load output and extending maintenance intervals.

The new upgrade also features the best of GE’s research and development centers in both the United States and Switzerland, including unique engineering elements:

- A low-pressure turbine used in GE’s H-class technology.

- High-pressure turbine improvements to increase efficiency, utilizing GE’s F-class technology.

- Advanced combustor engineering incorporating additive manufactured parts to deliver high performance, reduce cooling requirements by approximately 15 percent and lower relative emissions.

- A new 3D aero-profile compressor configuration to provide best-in-class base-load and part-load performance.