www.industryemea.com

01

'19

Written on Modified on

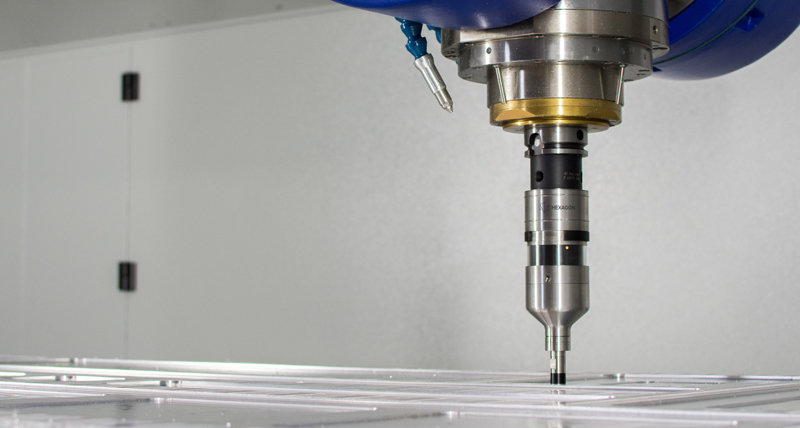

Hexagon transforms thickness measurement on machine tools

An innovative ultrasonic touch probe from Hexagon for measuring thickness directly on the machine tool significantly reduces inspection times and enhances data capture.

Inspecting the thickness of a part’s walls is typically a time-consuming manual process that takes place off the machine tool, resulting in downtime. The new RWP20.50-G-UTP touch probe from Hexagon transforms the procedure by using ultrasound to automatically measure wall thickness within the machine tool installation.

Maximilian Macha, Head of Product Management for Machine Tool Measurement at Hexagon, says: “The RWP20.50-G-UTP ultrasonic touch probe now makes it possible to perform a whole new range of thickness measurement applications directly on the machine tool. Designed with ease-of-use in mind, the RWP20.50-G-UTP’s not only automates and speeds up inspection processes, its software also makes it simple to view and use captured data. And because it works in a similar way to other Hexagon probes with radio-wave transmission, it reduces the training requirement for machine operators.”

Integrating Hexagon’s proven, innovative radio-wave technology, the RWP20.50-G-UTP operates in the 2.4 GHz frequency range. Like other probes from Hexagon, the RWP20.50-G-UTP has a robust, modular design and can be converted into a dimensional or temperature probe simply by changing the measuring unit. And unlike other ultrasonic solutions, the RWP20.50-G-UTP works without any coupling fluids, which simplifies operations and keeps parts cleaner.

Supported by dedicated thickness measurement software, the RWP20.50-G-UTP is compatible with the control software for Siemens, Heidenhain and Fanuc tooling machines, making it easy to capture and visualise measurement data directly on the shop floor and to export it for use in other programs.

www.hexagonmi.com