www.industryemea.com

13

'20

Written on Modified on

Motion control and automation for the optics and photonics industry

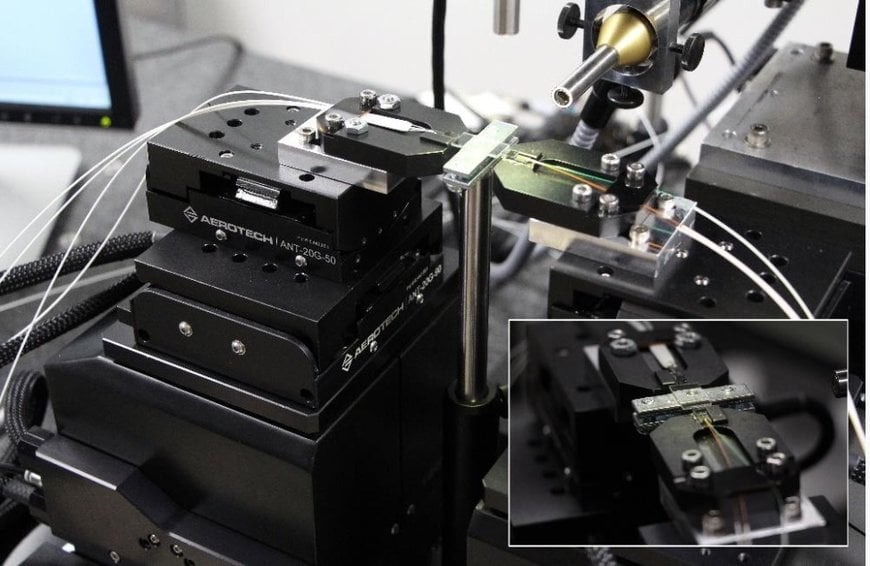

During the international trade fair for optical technologies, components and systems on November 17-19 in Frankfurt am Main, Aerotech will exhibit motion control and automation solutions for the optics and photonics industry. A focus will also be high-precision solutions for the alignment of optical fibres and other photonic devices.

“For us, Optatec is an international industry event that aligns very well with our capabilities and solutions for industrial applications in the areas of optoelectronics, fibre optics and laser components” claims Simon Smith, European Director of Aerotech. “We will be launching our new ‘small’ hexapod at the exhibition, the HEX150. The supporting program with top-class specialist lectures is an excellent knowledge platform and the SPECTARIS workshop and technology park will provide a lot of good industry insight.”

Aerotech is a globally recognised specialist for precise motion control and automation since 1970. From standard mechanical positioning stages and control systems to customer-specific automation systems, Aerotech solutions support manufacturing, test and inspection processes in the micron to nanometre range for many well known technology companies, as well as research institutions globally. The company offers many standard servo and piezo nanopositioning systems with comprehensive controls options, but where a standard solution will not work, custom specifically engineered solutions are available together with the necessary engineering design services, as well as software and algorithms for automating the alignment of glass fibres and optical devices.

Control platform: The Automation1 hardware has a built-in digital and analogue I/O, allowing an easy integration of complex motion and the associated control of process tools.

Well positioned for photonics applications

In many areas, fibre optic technology has become indispensable and photonics applications are growing rapidly. Modern Photonic Integrated Circuit technology, test and measurement technology or illumination and lighting technology for medical applications are hardly conceivable today without the use of optical fibres and photonic devices. With the increasing maturity of the many applications, automated alignment and testing systems are of enormous importance. Automated technologies significantly improve the precision of optical assemblies and at the same time reduce production costs as soon as the number of items increases.

The selection and implementation of a suitable positioning system can be decisive for the automated alignment process, for example connection of optical fibres to Photonic Integrated Devices can only be automated through exact positioning and motion control.

The motion control technology must allow submicron alignment adjustment in many degrees of freedom. The use of motion kinematics plays an important role here in order to optimise the pre-adjustment of components and finally the alignment of the optical fibres. The use of precision positioning systems ensures optimisation of the optical performance even under difficult space constraints.

“Not everyone knows that at Aerotech we have been supporting the telecommunications industry as well as data centres for decades in using fibre optic cables for data transmission”, emphasises Simon Smith. “We have products and solutions for the exact positioning of the optical components and software algorithms to minimise the optical losses during alignment of the devices.”

Hexapod HEX150: Here still as a 3D model. The size comparison with a coffee cup shows how compact the HEX 150 from Aerotech is.

Automation1 brings a new momentum to motion control and positioning systems

Aerotech develops motion control and positioning systems and associated software solutions. These are used wherever high throughput with high accuracy is required, for example in laser material processing. Controlling movement components with high precision has been a core competence for decades. Aerotech solutions and systems are used in manufacturing, research institutions or test and inspection technology, wherever something in the micron and nanometre range needs to be positioned with repeatable accuracy. With Automation1, the next generation of control has arrived adding further features and benefits above Aerotech’s Automation 3200 controller. By using Aerotech’s control platform significant reductions in non-value added optimisation and development time can be realised and allows customers to delivery their equipment faster.

Aerotech revolutionises precision motion and machine control with the “Automation1 Precision Machine and Motion Control Platform”. It functions as a complete machine control system supporting many industrial components and thus offers significantly more than just “motion control”. As a software-based motion controller many different motor technologies are supported including linear and rotary servomotors, stepper motors, galvo scanner, piezoelectric actuators and various other devices, all controlled directly as ‘just another axis’, integrating all the technologies into one control platform. The individual motion axes controllers are connected via Aerotech’s HyperWire bus, the most powerful communication bus in the motion control industry offering industry leading datarates whilst offering <1nS network jitter.

According to Aerotech, the new Automation1 platform supports today's growth markets for precision machinery and motion control, and is particularly well-suited for automation systems, precision laser processing, test and inspection equipment, and other applications where process control is closely linked to motion. The new control and drive development offers even greater optimisation potential for faster motion, decreased settling times, better inposition stability and increased contour accuracy. It is thus the first motion control development environment that simultaneously puts years of user experience together with the latest control technology for precise and fast motion sequences into the forefront of product design.

www.aerotech.com