www.industryemea.com

19

'20

Written on Modified on

GEA launches ABF 2.0 filling system for shelf-stable, sensitive beverages and milk-based drinks

The new rotary Aseptic Blow Fill technology from GEA (ABF 2.0) provides beverage manufacturers with maximum hygiene and food safety and top performance in terms of filling speed, accuracy and flexibility.

ABF 2.0 is suitable for the filling of shelf-stable, sensitive beverages and milk-based drinks, using H2O2 for the sterilization of PET preforms. With the ABF 2.0, GEA has used all its experience to optimize Total Cost of Ownership (TCO) while enhancing the control of key parameters to eliminate any potential risk to the product. The ABF 2.0 can fill a full range of sensitive beverages including still, clear drinks with or without particles, and carbonated drinks - high or low acid.

In the 1990’s, when the aseptic systems were enclosed in large white rooms to fill in a sterile environment, GEA launched in the market an innovative way to confine and minimize the air volume to be kept in aseptic conditions around the filler and so to protect the product: the Microbiological Isolator. With the ABF technology launched back in 2010 GEA has confined inside the Microbiological Isolator also the aseptic Stretch Blow molder, thus forming together with the filler and capper module a state of the art system for a product protection with no compromises and providing numerous benefits to users including reduced bottle weight, the option to develop increasingly complex and attractive bottle designs and allowing for the elimination of air conveyors, bottle sterilization and rinsing turrets. The whole system resulted more compact than traditional aseptic technology and required fewer operators.

New features for efficiency and control

The new ABF 2.0 is an evolution from the original that includes many mechanical improvements and simplifications. These reduce power consumption while eliminating any potential risk of contamination by ensuring that every step of the sterilization process is carefully planned, controlled and properly managed. Every process parameter and critical point is carefully monitored and traced to ensure reliable and repeatable sterilization performance. As an additional guarantee of reliable and efficient sterilization treatment, a Smart Sensor monitors spraying performance at each sterilization nozzle. This helps to guarantee the safety and quality of the final product, with the speed, accuracy and flexibility customers want.

When it comes to food and product safety assurance throughout the entire lifecycle of a machine, the ABF 2.0 represents the state of the art in the aseptic technology market, especially for the highest sensitive products. In order to guarantee a fully reliable and aseptic process it is of the utmost importance to have a fully automated monitoring of the entire running operations leaving no space at all to semi-automatic or manual procedures. This is exactly the concept behind the GEA ABF 2.0.

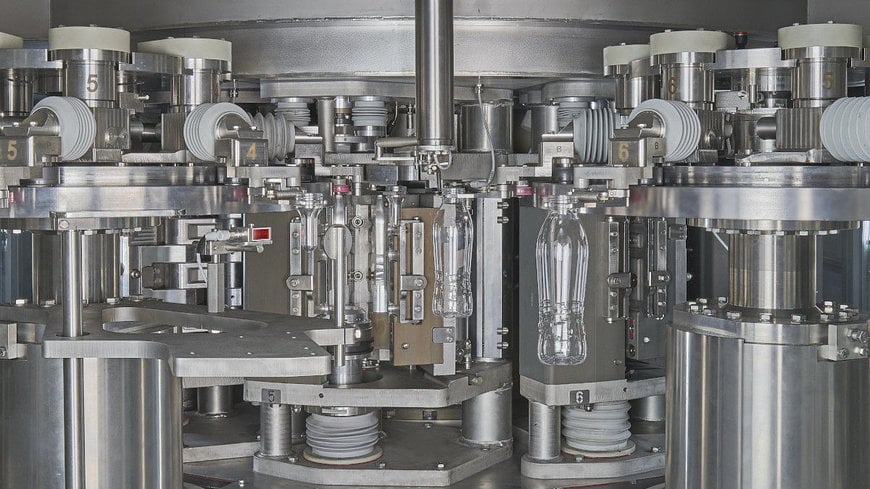

The GEA Aseptic Blower, which is part of the ABF 2.0.

Unlike the original machine, the preform does not need to be turned along the transfer to the aseptic blower: this saves time and reduces maintenance costs. A new oven with optimized materials allowed to have fewer heating modules, this has achieved a significant reduction in power usage and the overall oven footprint. The introduction of an air recovery system in the blowing module has reduced power usage in that area as well. These innovations combine to provide users with a noticeable reduction in TCO.

Internal surfaces of the GEA ABF 2.0 aseptic blower can be cleaned by foaming and sterilized by VHP.

The aseptic blowing wheel is located within the sterile zone with the filling and capping processes. This means that the sterile container does not leave the sterile area until the filling and capping is complete. This rigorous aseptic process ensures that the environmental contamination level is always under control.

The bottle caps are sterilized using Sterilcap VHP R from GEA. This is unique technology that provides gentle sterilization treatment at reduced temperature to avoid overheating the caps and includes a buffer to optimize the Overall Equipment Effectiveness (OEE) of the line.

Flexibility

Most bottling plants handle a wide variety of products so GEA has designed the format changeover system on the ABF 2.0 to be fast and simple. This has enhanced the flexibility of the machine so that it appeals to the widest range of customers especially those with multiple products. As companies work to achieve market share and product variety, the flexibility of plant operations is vitally important. The ABF 2.0 provides the versatility and control that they need.

The environmental cleaning and sterilization processes are completely automated and performed via a control panel without any manual manipulation from operators, that can represent a potential risk of contamination.

Thanks to its successful long-term experience in delivering technologies offering top food safety level, GEA is the only supplier that can propose FDA approved filling solutions for both PAA and H2O2-based applications. Being the evolution of a consolidated, FDA validated platform, the ABF 2.0 is ready to meet all FDA regulations, which represent one of the most stringent protocols.

www.gea.com