www.industryemea.com

26

'13

Written on Modified on

Quick-release latching enables rapid cab exit in an emergency

Southco’s Ulrike Sturman discusses the importance of fitting quick-release hardware as a means of escape from off-highway and construction vehicles in the event of an emergency

When designing for safety, a popular option is to also use the cab exit door – fitted with quick-release hardware - as a means of escape. Quick release latches allow the engineer to use this existing door as an emergency egress, while still allowing the door to be used as an exit during normal operation. This eliminates the need to cut out another panel in the cab, reducing the design complexity, additional structural support and weight that goes along with the installation. Using a cab door that doubles as an escape hatch helps to reduce the amount of hardware and number of parts used to install and operate the door. Furthermore, by combining the two essential requirements of both normal and emergency exit into one solution, installation and labour costs associated with vehicle production are lower.

Due to the nature of the business, cab escape doors must be outfitted with robust parts that provide secure latching, resist vibration, and offer fast, simple access. Escape door application specification must effectively combine vehicle functionality with operator security. When specifying an escape hatch application, it is essential that engineers use a company which understands the needs of the off-highway industry.

Best-in-class quick release hardware should include the following characteristics: high cycle life; corrosion resistant finishes; high strength steel construction; over-centre latching design: and ease of identification.

One of the foremost names for quick-release fastening – and one which fulfills all the above mentioned criteria - is Dzus, a Southco brand presenting the world’s most comprehensive range of quick access and robust fasteners. With an established reputation spanning nearly seven decades Dzus is today’s optimum choice of quick-access fasteners within the global off-highway and construction vehicle industry. An additional advantage to operators opting for the Dzus solution, is that they benefit from Southco’s wealth of experience working with leading construction vehicle manufacturers to develop quick-release latching mechanisms specifically developed for escape doors and hatches.

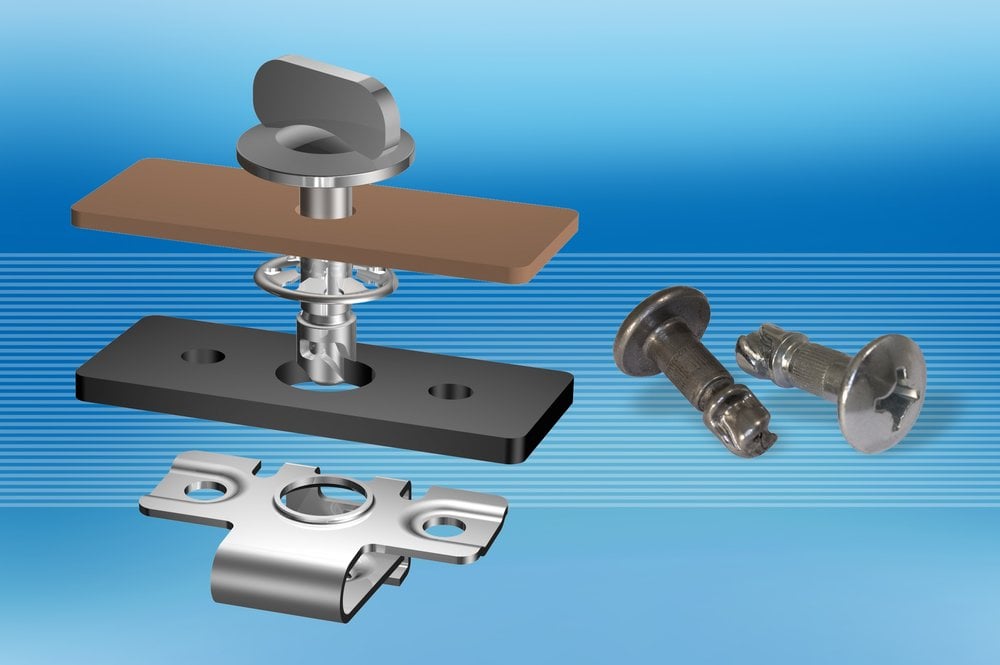

Each product line comes with its own set of matching receptacles for accurate, secure engagement and convenient mounting in escape door and hatch applications. In addition, Dzus offers the advantage of low installation and assembly costs, fast repeatable access, fast service calls, better ergonomics and improved aesthetics. Other benefits include captive fastener options to protect against lost hardware or equipment caused by dropped fasteners, and an extensive choice of headstyles.

In off-highway vehicles, the access hardware chosen for escape door and hatch applications can make all the difference in on-the-job emergency situations. With Dzus quick access fasteners, the robust construction of the latch and its simplified functionality ensures the operator’s safety during operation by holding the door closed at the same time as enabling fast access when the operator needs to exit the vehicle in an emergency.