www.industryemea.com

12

'20

Written on Modified on

TE Connectivity’s AMPMODU 2 mm wire-to-board crimp receptacles and shrouded headers free up space on printed circuit boards

TE Connectivity (TE), a world leader in connectivity and sensors, is freeing up valuable space on printed circuit boards (PCBs) for design engineers with its new compact AMPMODU wire-to-board receptacles with crimp contacts and shrouded headers. With centerline distances of 2 mm, they occupy 38 percent less space on a PCB than connectors with a 2.54 mm [0.100”] centerline.

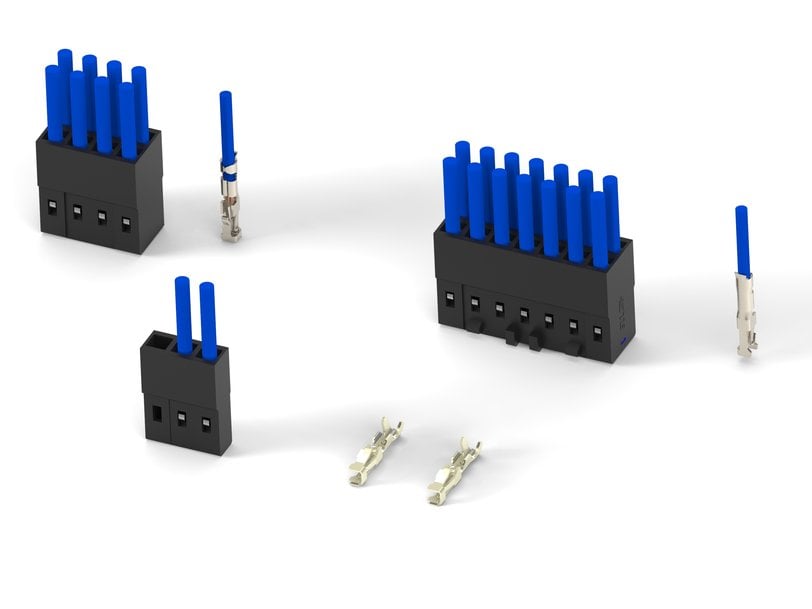

TE’s wire-to-board receptacles offer a variety of housing styles and crimp contacts for wire sizes between 30 and 24 AWG [0.05 – 0.22 mm2]. Receptacle assemblies provide a large and reliable contact surface between the header pin and receptacle contact by using phosphor bronze contacts with dual cantilever beams with gold or tin plating. Housings are available in a single and double row, from 2 to 25 positions per row, and wire termination is easily accomplished with TE recommended hand tooling or applicators.

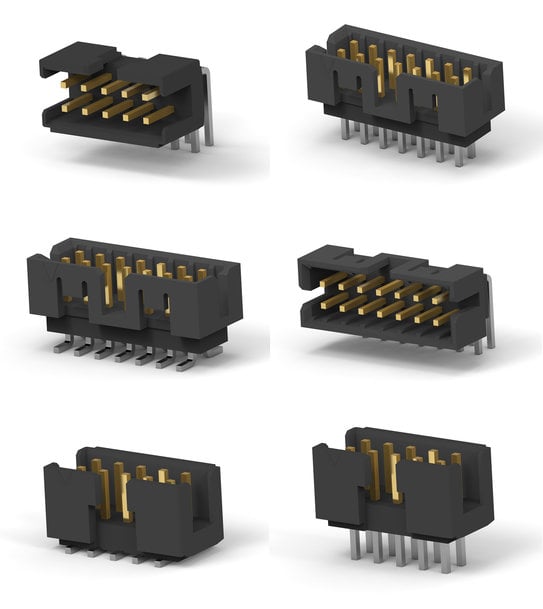

Receptacle assemblies are intended for use with TE’s existing 2 mm breakaway headers and our new shrouded headers. Shrouded headers come in a double row configuration, are available in vertical and right-angle orientations and include both through-hole and surface mount termination variants.

The AMPMODU 2 mm product family includes a detent latching housing version for use in high-vibration industrial environments. All connector housings are molded in a high-temperature resistant resin making them suitable for reflow soldering process. The connectors offer a maximum current rating of 2 A and a maximum operating voltage of 125 V.

“Our new AMPMODU 2 mm connectors reliably and economically meet the interconnection requirements of today's miniature sophisticated electronics,” says Sameer Trikha, global product manager. “With miniaturization of PCBs continuing to be a trend in our industry, these products help increase design flexibility and are able to meet a wide variety of customer requirements.”

Common applications include PLC /IO devices, industrial robotics, servo drives, industrial automation and control equipment, material handling equipment, instrumentation & test equipment, and building and home automation devices.

www.te.com