www.industryemea.com

17

'20

Written on Modified on

High torque, flexibly integrated

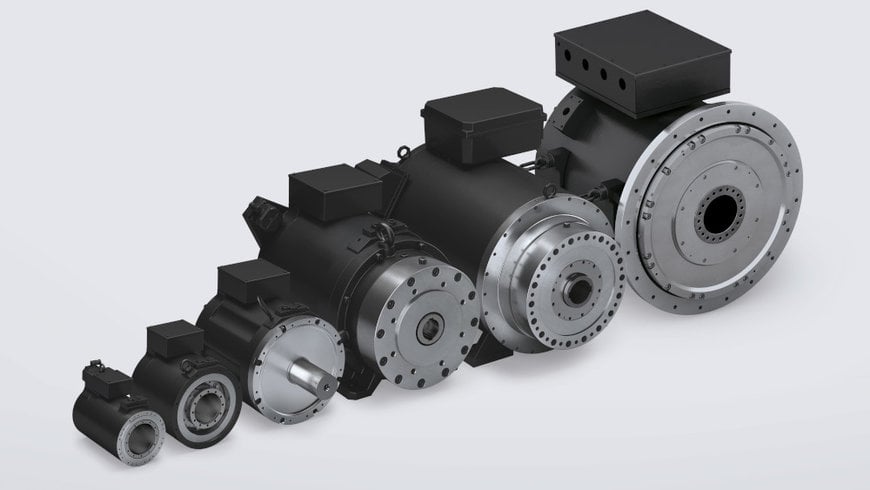

Baumüller offers torque motors with variable assembly options for optimal machine design.

The drive and automation specialist Baumüller is one of the top manufacturers of torque motors on the market. With a torque range from 325 Nm to 60,000 Nm, the motors in the DST2 series are used as direct drives in many applications, among them extruders, injection mold machines, presses and ships. Direct drive technology is being used ever more frequently as an alternative to hydraulic systems or classic motor-transmission combinations and succeed with their comparatively smaller installation space, the good response times, a longer service life and lower maintenance costs.

What allows these advantages to be realized is the optimal integration into the machine. For that reason, Baumüller offers its DST2 motors with different installation options.

Classic solution: Hollow shaft

The classic option for direct drives is the version with hollow shaft, which offers high rigidity and thus good power transmission. The connection to the machine can be made using e.g. a clamping set, a shrink disc, a hydraulic clamping bush or a ball screw. All of these connections are suitable for very high torques. It is thus possible to meet a full range of requirements, from high positioning precision to quick installation to compactness, depending on priority.

Maximum flexibility with kit motor

With the kit motor solution, machine builders have extra flexibility in integration. In this case, the customer is only provided with the active parts of the motor, i.e. the rotor and the stator without the housing and bearing, which allows optimal integration into the machine.

Industry-specific solutions

One industry-specific solution is the version with thrust bearing. Thrust bearing motors were specially designed for direct drives, e.g. in extruders. Here the extruder screw is directly coupled with the blind hole of the motor. The application-specific high axial forces are absorbed by the axial spherical roller bearings used here, without additional steps being required.

In addition, the DST2 torque motors with solid shaft or as customer-specific option are also available with blind hole shaft.

With this wide selection of integration options, the Baumüller torque motors offer an extensive range of applications, thereby easing the transition from high-loss hydraulic solutions and classic motor-transmission combinations to direct drive technology.

www.baumueller.com