www.industryemea.com

28

'13

Written on Modified on

AdduXi achieves utmost quality with Keyence's IV Series.

This cost-effective vision sensor allows AdduXi to carry out more inspections on its production lines with the greatest ease.

"We advocate using vision systems for in-process inspection, but some highly advanced systems are not suited to all applications. In other words, not only were we looking for affordable vision systems, we also needed a solution that was highly stable and utterly simple to use. You see, our facilities operate 24/7 but our vision specialists go home at the end of the day," says Christophe Paviot, Manufacturing Engineering Manager at AdduXi's site in Bellignat, France.

"We looked at a number of vision sensors of similar type. However, either their detection capabilities weren't optimal or they were too complicated to operate. Keyence's solution proved to be the best one. It was very easy to set up and we had it up and running on our production lines in no time. Best of all, no extra lighting was necessary; all we added was a filter. There are now eight vision sensors operating at our facilities round the clock and without any stability issues," adds Mr Paviot.

The IV sensor offers excellent detection stability thanks to a range of innovations. Its HP-Quad lens contains 4 layers of glass to achieve low aberration and gather a maximum of light. The HS-HDR function broadens the light-receiving sensitivity range when dispersion occurs in reflections and a polarised filter eliminates glare from shiny targets.

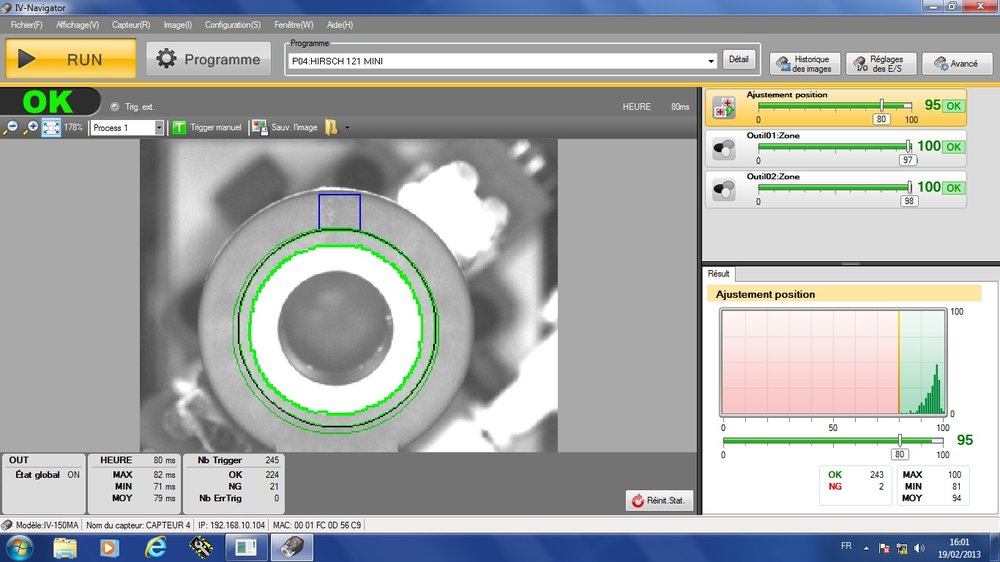

"Although the IV sensor is quite recent, we've already installed it on four production lines. We use it on three assembly lines to detect the presence or absence and correct positioning of inserts as well as on a coil overmoulding line to check for the presence of material across the entire surface to be covered," explains Mr Paviot.

This new cost-effective sensor by Keyence places vision systems within reach of anyone. It takes about a minute to set up, even by a novice. It meets 80% of vision needs with a very high level of accuracy and is an advantageous alternative to using one or more sensors to detect targets of varying position. The outline recognition technology allows automatic position compensation. The IV Series performs all normally needed adjustments in real time. The Intelligent Brightness Adjust function (IBA) automatically adjusts the brightness of the built-in lighting. The autofocus function ensures sharp images and is driven by a motor engineered specifically for the IV Series. Last but not least, the IV Series is the first-ever vision sensor in its price range to offer both colour detection and autofocus capabilities.

The IV Series is thus a flexible solution that in most cases can meet a large portion of the needs of production facilities. In comparison, three or four sensors of different makes are often needed to achieve the same level of functionality. There are eight different sensor heads to meet the specifications of each application – detection distance (up to 2000 m), field of view and exposure time (up to 1/25000 for high rates).

"Not only do Keyence make quality products, they are also always on hand to help us find the best detection solution for our needs. They come out at a moment's notice to conduct tests with their equipment so that we can choose the best sensor or vision system solution for our needs," concludes Mr Paviot.