www.industryemea.com

05

'20

Written on Modified on

RESOLUTE encoders give focus to big science

French technology company IRELEC Alcen, based in Grenoble, manufactures optomechanical and robotics systems for synchrotron facilities worldwide.

Background

French technology company IRELEC Alcen, based in Grenoble, manufactures optomechanical and robotics systems for synchrotron facilities worldwide.

A synchrotron (a type of particle accelerator) is an extremely powerful source of X-rays, which is used for scientific research in fields such as materials physics, chemistry and molecular biology. One example of such a facility is the Diamond Light Source (DLS) in Oxfordshire, UK.

This research involves placing an experimental sample at the end of a beamline, one of many specific paths of X-rays generated by a synchrotron. Each beamline can be used for experiments that probe the molecular structure, composition and physical properties of a sample.

IRELEC specialises in the manufacture of custom mirror systems that focus X-rays on a target. Renishaw's position measurement products have helped IRELEC to push the boundaries of synchrotron science for over fifteen years.

Challenge

The perfect shape for a focusing mirror is an ellipsoid, but ellipsoidal mirrors are difficult to manufacture. An alternative approach is to use a pair of mirrors arranged perpendicularly to each other which focuses the beam in two dimensions: a Kirkpatrick-Baez (K-B) mirror system is a well-known example.

K-B systems are usually mounted on a series of in-air and in-vacuum motion stages that use position encoder feedback to precisely control mirror translations and rotations in the beam. Due to the small grazing angles of incidence of the X-rays on each mirror, the correct mirror shape is achieved by the application of bending forces. Actuators attached to the ends of each mirror also require encoder feedback to precisely control the mirror shape.

Beamline optical paths can be hundreds of metres long and require mirror positioning systems with translational accuracies of better than 0.5 µm and angular resolutions down to 0.1 µrads.

Position encoders selected for in-vacuum stages must be ultra-high vacuum (UHV) compliant and robust enough to endure sustained bake-out temperatures of 120 ºC.

Raphael Richaud, IRELEC's Business Development Manager, highlights the environmental constraints of beamline optics:

“Everything is under vacuum (10-10 to 10-9 millibar); therefore, all equipment has to be UHV compliant. Encoders need to be certified for high-vac applications. They also have to withstand irradiation, and high temperatures for when you proceed to some bake-out procedures. For this kind of system, you need to de-gas by heating, so the encoder must survive continuous heating over 100 ºC for up to three days.”

We were impressed by the capabilities of the RESOLUTE UHV encoder system, it fully meets our requirements including robust mechanical design, suitability for high-temperature bake-outs and resistance to radiation ageing. Renishaw's encoder really does the job.

IRELEC Alcen (France)

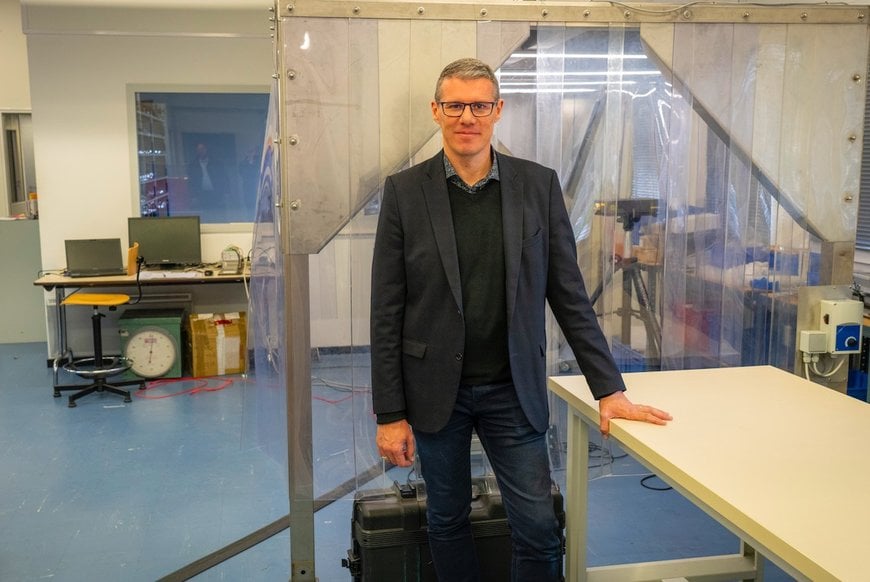

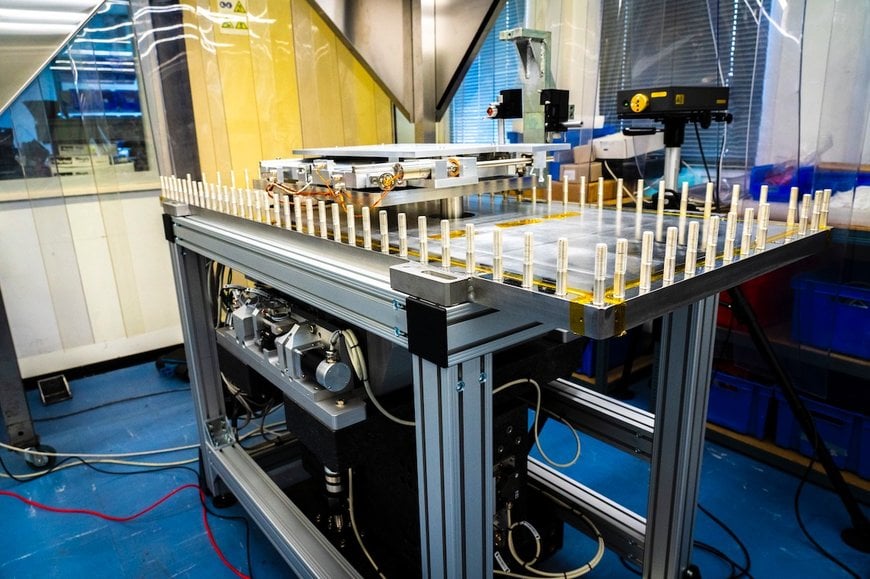

Mirror platform with both in-air and in-vacuum motion stages

Solution

IRELEC builds bespoke mirror solutions that meet a wide range of customer requirements. Two years ago, the company built the in-vacuum stages of the K-B system required for the new Dual Imaging and Diffraction (DIAD) instrument at DLS, which is currently being commissioned.

DIAD will be a dual beam instrument capable of simultaneous imaging and diffraction at the micron scale. The DIAD K-B mirrors are designed to scan (raster) an X-ray microbeam across a sample at high speeds. In this case, lateral displacements of just 100 microns are enough to traverse the whole sample.

Fast motions can cause resonance in the mechanical structure of K-B systems, which must be controlled. Mechanical support structures are ideally designed to present a first resonance (eigenfrequency) above 65 Hz. The system must also be repeatable, within a stability specification, after mechanical shock (without damage). Integrated encoders are robustly mounted on stiff mechanical flexures to help minimise vibration during mirror translations.

IRELEC has chosen Renishaw's RESOLUTE UHV absolute encoder system with linear RTL30 scale for motion control of the in-vacuum elements of its mirror systems.

Mr Richaud explains the advantages of Renishaw's RESOLUTE UHV encoders in these applications:

“The first encoders we integrated were in air. Very quickly, we required encoders for mechanisms in a vacuum and we asked Renishaw if they could provide a UHV compliant encoder. We were impressed by the capabilities of the RESOLUTE UHV encoder system; it fully meets our requirements including robust mechanical design, suitability for high-temperature bake-outs and resistance to radiation ageing. Renishaw's encoder really does the job.”

Prior to delivery to the customer, each IRELEC mirror system is calibrated and qualified using Renishaw's laser calibration system. Renishaw's XL-80 laser interferometer, which has superseded the ML10 laser, is a fast, accurate and extremely portable interferometric measurement system with a linear accuracy of ±0.5 ppm.

Schematic of a K-B mirror system showing mirror degrees-of-freedom with optical path in red

Results

Renishaw's encoder systems have supported IRELEC's synchrotron optics solutions for over a decade. As technology advances and end-user requirements become more stringent, Renishaw encoders continue to keep pace by combining cutting-edge technology with excellent technical support.

“A good part of the relationship with Renishaw is the high quality technical support. It means that time and money is saved”, Mr Richaud says.

RESOLUTE UHV encoders offer high accuracy, low jitter (noise) for superior position holding, robust design and UHV capability. The RESOLUTE family of encoders is well positioned to meet the future challenges of beamline optics technology.

Mr Richaud concludes with his vision of the future:

“The main challenges of mirror systems revolve around mechanical stability. The newest generation of synchrotrons produce very small beams and you need positioning systems with very high stability. Now customers want the first natural frequency (resonance) of this system to be above 100 Hz. Which is a big challenge, so you need to make something that is highly stiff whilst also providing all six degrees of freedom on a mirror to accurately control position and ensure that it will stay in place without any vibration and drift due to thermal effects. So, mechanical stability and thermal stability are challenges of the future.”

Aymeric Cunrath, IRELEC Technical Manager (left) and Raphaël Richaud (right)

www.renishaw.com