www.industryemea.com

07

'20

Written on Modified on

ConSite® Mine developed by utilizing IoT and AI technologies helps maintain availability and extend the life of valuable mine equipment

Advanced digital technology helps mining customers and service providers extend equipment life and improve productivity and safety by providing the information to predict equipment issues, such as visualizing signs of structural cracks.

Hitachi Construction Machinery Co., Ltd. (TSE: 6305; “Hitachi Construction Machinery”) and its consolidated subsidiary, Wenco International Mining Systems Ltd. (“Wenco”) have jointly developed “ConSite® Mine,” which helps resolve problems at mine sites by remotely monitoring mining machines on 24/7 basis through the use of IoT and AI based analysis of equipment operations data.

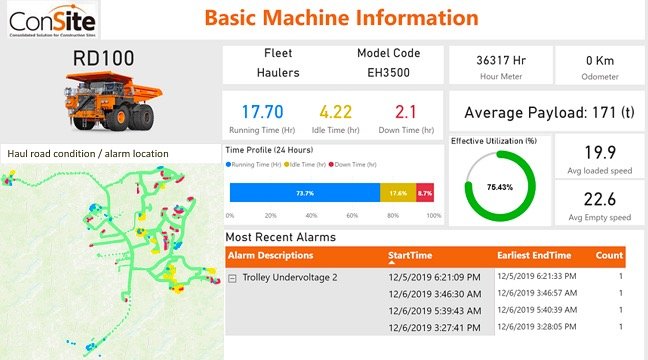

Hitachi Construction Machinery has developed this technology to help customers and Hitachi Construction Machinery dealers predict costly maintenance issues before they occur, such as the occurrence of cracks in and excavator boom or arm by utilizing machine learning and applied analysis technologies. Detailed information from these predictive alerts are provided on the web-based ConSite® Mine dashboard and other items.

Currently, Hitachi Construction Machinery Group is piloting the technology in Australia, Zambia and Indonesia. “ConSite® Mine” will be further modified based on customer feedback before wider commercial release in 2021.

ConSite® Mine will enable the maintenance professionals for customers and Hitachi Construction Machinery dealers to monitor equipment health in real time and anticipate issues before they occur. The service technician supporting the customer can analyze asset health information in real time using the online dashboard. The technician can pre-order parts and schedule planned maintenance, avoiding the costs and delays of unplanned downtime from failed equipment.

“ConSite® Mine” can also improve overall productivity and safety, by monitoring conditions associated with operator behavior, equipment location and speed, fuel consumption and other data for each equipment and operator, providing real time and historical information which contributes to safe operation and productivity improvement.

Wenco technology and Hitachi Construction Machinery’s “ConSite” are registered “Lumada” that is a collective name for advanced digital solutions, services, and technologies of the Hitachi Group. Wenco provides the IoT digital platform and software technology by which large-volume data are collected and displayed on a customized dashboard for each customer.

Hitachi Construction Machinery leverages its accumulated knowledge, through “ConSite®,” on data analyses, information processing technology and applied analysis technology for structural parts of excavators and haul trucks. ConSite® Mine enables real time predictive analysis of operating data that delivers actionable information to customers. With ConSite® Mine,safety and productivity of mining machines can be improved and their life-cycle costs reduced.

The Hitachi Construction Machinery group has provided “reliable solutions” to challenges faced by our customers as a close and reliable partner. We will expand parts and service business in the mining sector and further strive to resolve global societal challenges.

Some of the technologies and features of ConSite® Mine include the following:

1. “Load Index,” an AI technology which predicts an occurrence of cracks in the boom and arm of an ultra-large excavator, is an predictive maintenance capabiliity available to “ConSite® Mine” customers.

Loads to welded structural parts such as the boom and arm vary considerably according to how the excavator is used. “ConSite® Mine” collects data from the sensors provided as standard on EX-7 series 190 to 800-ton ultra-large excavators, analyzes cumulative loads of the boom and arm by utilizing AI and applied analysis technologies, and predicts the occurrence of cracks.

Since the sensors provided as standard are utilized as opposed to strain gauge sensors which are retrofitted, welded structural parts can be monitored continuously and maintenance can be implemented at appropriate timings according to their conditions. Thus, “ConSite® Mine” contributes to lowering life-cycle costs and minimizing downtimes of excavators. It can also be useful in providing advice on how to improve the operation of excavators. “Load Index” is a unique technology which enables prediction of occurrence of cracks in the boom and arm of an excavator.

Load analysis of the front-end structures

2. Detection of signs that indicate failure of the hydraulic pumps

“ConSite® Mine” detects signs that presage failure of hydraulic pumps of an ultra-large excavator and inform of possibility of failure. Applicable components will be added in the near future.

3. Visualization of operators’ operational patterns of rigid dump trucks

“ConSite® Mine” collects data form the sensors provided as standard on AC-Ⅱ and AC-3 series 180 to 290-ton rigid dump trucks, and distinguishes unsafe or inefficient operations such as hard braking, free spinning of tires, over-speeding and running over bumpy haul roads from operating data and displays the locations where such incidents occurred on a map. The visualized information can be utilized for re-examining haul roads, dispatching of trucks or education of operators to reduce risks of accident and improve productivity.

In the future, we will make use of our knowledge as a construction machinery manufacturer to propose the types of data, indicators, and timing of alarms to suit the conditions at the mine site and the needs of the customer

Visualized operating patterns of an operator of a rigid dump truck

4. Selection of the most optimal tuning pattern of rigid dump trucks for each site

There are various haul road patterns at mine sites including slippery, twisted and uphill roads, and “ConSite® Mine” offers a function to tune certain parameters such as the engine rotating speed and the accelerator responsiveness of dump trucks to reduce fuel consumption. Up to now, service mechanics had to sequentially try various settings of each parameter to set an optimal tuning, which took a long period of time.

With “ConSite® Mine,” since traveling data of a rigid dump truck is automatically collected and the effects of each parameter on fuel consumption and traveling performance are automatically analyzed, the most optimal tuning can be determined in a short period of time. We will further strive to develop a function to auto-propose the most optimal parameter settings and one to auto-judge each parameter.

5. Application of ConSite® OIL

ConSite® OIL, which has a high reputation for medium- and small-sized construction equipment, will be applied to ultra-large hydraulic excavators. By utilizing sensors which monitor the excavator’s hydraulic and other oils, the condition of these oils and associated components can be evaluated. Since maintenance, inspection and replacement of parts can be implemented according to conditions of the parts and components, the excavators are kept in a good working condition, which contributes to stable operation of mines.

6. Recording chronologically of mining equipment operation data in the cloud

Equipment operations data and operators’ operational patterns can be recorded in the cloud. This data can be used by the customer’s maintenance personnel and the Hitachi Construction Machinery dealers to investigate the cause of the incident over time, and can also be used to train the operators to reduce the risk of the incident and improve safety.

www.hitachicm.com