www.industryemea.com

29

'22

Written on Modified on

FLEXIBLE, FAST, AND SUSTAINABLE WITH THE COMPREHENSIVE DIGITAL TWIN FOR INTRALOGISTICS

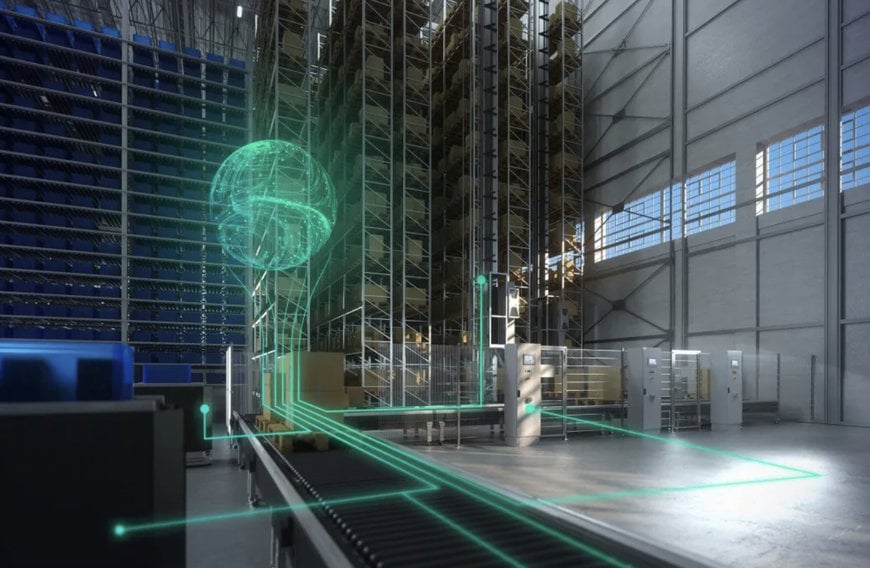

Under the motto "Intelligent intralogistics - experience the flow", Siemens will present at this year's Logimat in Hall 3, Booth D11, how a comprehensive digital twin is developed with the Digital Enterprise Portfolio by digitalization in intralogistics as a decisive competitive advantage.

Simulation based on a digital twin makes it possible to design applications and processes in intralogistics in a highly efficient, flexible and intelligent way. Considering the fact that markets and requirements have changed in the past two years and the intralogistics industry has to cope with a rapidly growing e-commerce, this contributes to sustainable competitiveness. Here, increasing inventory turnover rates with shorter storage periods, small order quantities with high delivery speeds, rising return rates and short-term increases in delivery quantities require flexible and scalable intralogistics processes. The new requirements can be managed with the help of digitalization and automation.

At Logimat, Siemens will use a Dynamic Gapper application to demonstrate how a digital twin helps to meet new intralogistics demands. In this typical intralogistics application, two upstream conveyors bring parcels of different sizes and not uniformly seperated onto a common conveyor belt, where the parcels are then being placed and separated within the right defined distance between each other. The technology company shows both the real application and its simulation. The precise simulation takes place before the actual construction is started. This allows the application to be virtually optimized and validated, which reduces the development and engineering time for machine builders by up to 35 percent. Operators of logistics centers also benefit from the digital twin, because with its help commissioning times can also be reduced by up to 40 percent. The entire hardware as well as the control system with all functions including communication, safety and web server can be simulated as part of a virtual commissioning. In the meantime, the real application can be built and wired and is ready for the actual commissioning. This then mainly consists of loading the program into the CPU and transferring the parameters to the drives.

The real application can also be further optimized during operation. By connecting to a cloud or edge platform, valuable process data can be collected and analyzed during operation. This enables operators of intralogistics centers to respond quickly to changes such as increased delivery volumes and create sustainable, flexible and scalable processes.

Siemens supports machine builders and operators of logistics centers on the path to digital transformation. The Digital Enterprise Portfolio offers an integrated product portfolio of software-based systems and automation technologies at the center of which is the digital twin. By using the digital twin of material handling equipment, warehouse operations and performance, the entire value chain is simulated and validated and can thus be designed optimally and efficiently. This consistently increases the efficiency of machine and plant construction and operation, minimizes error rates and downtimes, and shortens development times. Through the seamless interaction of the real and digital worlds, the technology company helps to increase the productivity and flexibility of plants and thus sustainably reduce the costs and energy consumption of logistics centers.

On May 17, 2022, the Siemens Intralogistics Forum will take place virtually. Participants will be able to experience a virtual warehouse as well as attend expert presentations on the topic of intralogistics. For more information and to register, please visit www.siemens.com/logimat

www.siemens.com