www.industryemea.com

09

'22

Written on Modified on

Extremely reliable and accurate gap control solutions

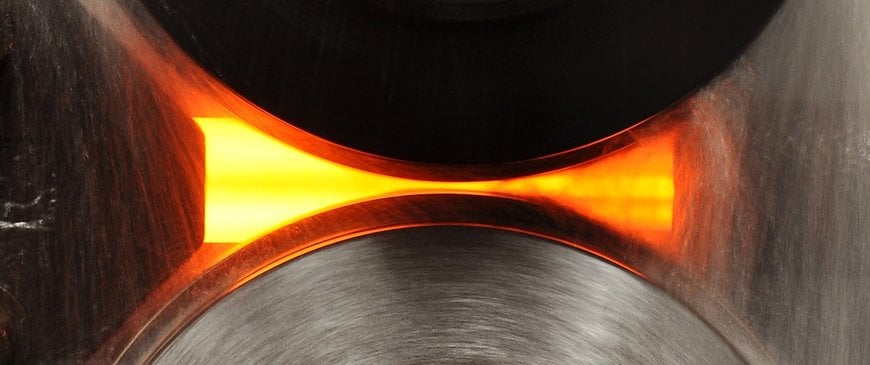

Do you strive for increased productivity, lowered material consumption and quality improvement? Leine Lindes gap control solutions are easily integrated in steel mills and other metal processing industries. We offer extremely reliable and accurate gap control, to assure both the quality of the end product and the lowest possible material consumption.

Are you an OEM manufacturer within the steel industry? With our linear system solutions, you will get precise control over product thickness, quality improvements, easy installation and integration, resulting in an extended lifetime of your machinery.

Or maybe you have a process where a single linear encoder could do the job? Regardless, we look forward to helping you with a customized solution for your specific needs.

Robust LINEAR 4000 SERIES encoders for the toughest of environments

Length measuring and roll gap control have become easy and reliable thanks to the high-resolution, very fast and accurate absolute position values received from our robust linear inductive scanning encoders.

The Leine Linde high-quality linear encoders withstands shock, extreme heat, dirt, magnetic fields, chemicals and vibrations. All Leine Linde linear encoders are extremely fast and reliable.

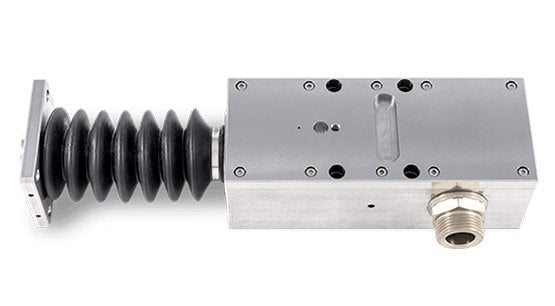

RLI 4300

System solution RLI 4300 is the perfect OEM solution. This linear high-end and durable encoder solution can be installed via a gateway, to gain access to most fieldbus interfaces and the freedom to integrate with your preferred automation system.

When using a gateway, it is possible to change the settings for your production unit at any time, and the fieldbus circuit will still be kept unbroken. This will improve both flexibility and stability in your production lines. These linear encoders are non-sensitive to disturbances and are easily accessible for maintenance.

RLA 4200

Leine Linde single linear encoder RLA 4200 can be mounted directly on the hydraulic cylinder of the rolling stand(mill) for example, which makes it easily accessible, both for installation and service. The aluminium encapsulated linear encoder is very cost effective as it is constructed with a separate air channel which eliminates the need for external compressed air.

This linear encoder is also very beneficial because there is no need for extra start time to find its position after an interruption - neither during commissioning nor at planned or unplanned stops.

www.leinelinde.com