www.industryemea.com

23

'15

Written on Modified on

MORGAN ADVANCED MATERIALS HIGHLIGHTS BENEFITS OF SUPERWOOL® PYRO-BLOC® MODULES

Morgan Advanced Materials (Morgan) has highlighted the unique performance characteristics of its acclaimed Superwool® Pyro-Bloc® modules for furnace and boiler lining systems, produced by its Thermal Ceramics business.

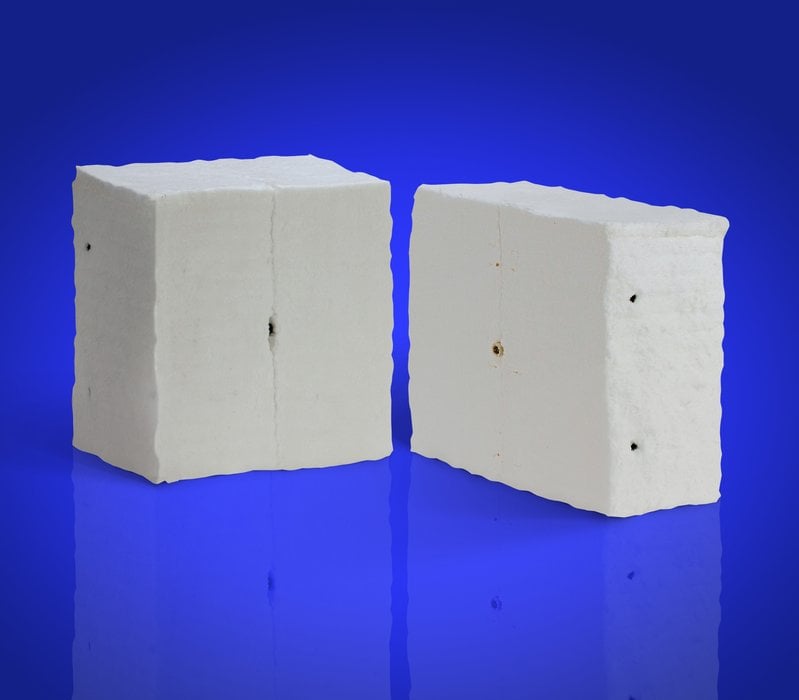

Pyro-Bloc modules have set the standard for quality and versatility in furnace and boiler lining systems since their market introduction more than 30 years ago. The only monolithic ceramic fibre modules on the market, Pyro-Bloc modules combine the insulation advantages of ceramic fibre with rapid furnace installation. Compared with standard folded modules, Pyro-Bloc modules feature higher density, better tolerance compliance, and superior resistance to erosion from high velocity gas. Pyro-Bloc modules are ideal for applications such as stack, flare and ductwork linings, as well as kiln car block and seals, burner blocks and peep sights.

Morgan’s Alkaline Earth Silicate (AES) fibre composition, marketed as Superwool, is available in densities of 160 and 192 kg/m³. Superwool Pyro-Bloc modules are offered in two temperature classification grades: Superwool Plus (1,200°C) and Superwool HT (1,300°C).

Due to Superwool’s low shot content, the thermal conductivity of Superwool Pyro-Bloc modules is typically 10 to 15 per cent lower than Refractory Ceramic Fibre (RCF) modules of the same density. In addition, improved heat storage properties result in savings on gas and energy and an improved work environment by lowering the skin temperature of furnaces and boilers.

Superwool HT Pyro-Bloc modules have high dimensional stability up to the classification temperature - critical for furnace and boiler applications where reduced linear shrinkage is important to longevity.

Pyro-Bloc Modules are installed with compression in both the vertical and horizontal direction, allowing designers to eliminate unsupported overhead battens and packing strips. In addition, the unique monolithic module structure of the modules decreases the number of through joints required by folded module systems; they can also be installed without a stainless steel shroud, demonstrating their ease of installation.

Superwool Pyro-Bloc modules’ monolithic edge grain surface is more resistant to high-velocity gas erosion than folded systems. Along with erosion resistance, the module surfaces will more readily accept any required post treatments due to the grain of the fibre, which allows a deeper penetrating bond of the substrate. Several such treatments are available, some improving velocity resistance by up to 35 per cent.

For further information visit www.morganthermalceramics.com/products/superwool-fibre/modules-bloc.