www.industryemea.com

07

'15

Written on Modified on

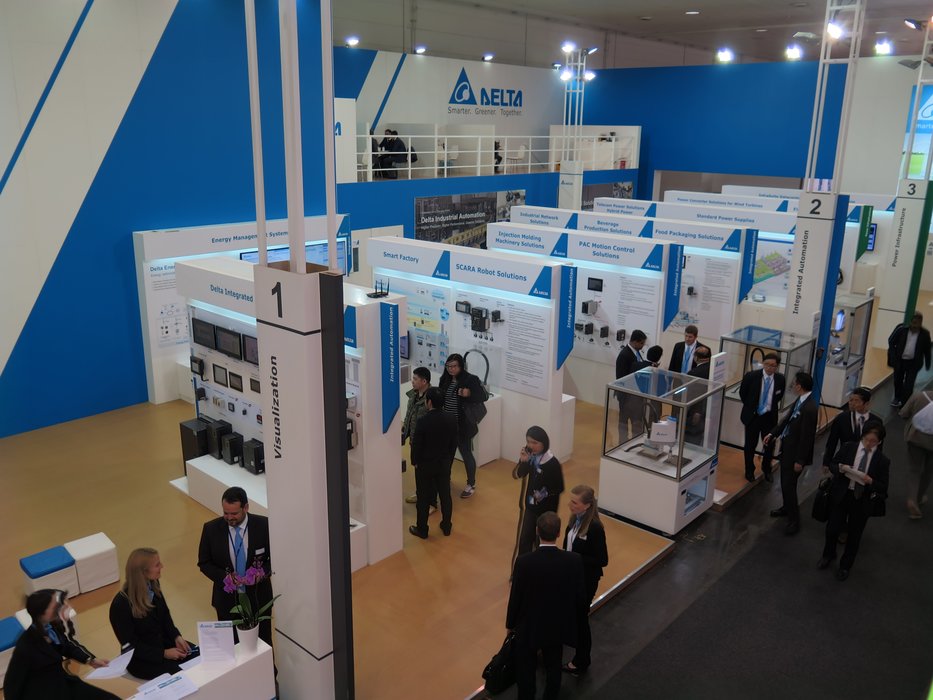

Delta’s Broad Portfolio of Smart Industrial Automation Solutions Showcased at Hannover Messe 2015 to Enhance Productivity Across EMEA and India

Hannover, Germany, April 13th , 2015 – Delta, a world-class provider of industrial automation solutions and a global leader in thermal and power management technology, announced today its smart industrial automation solutions, showcased at Hannover Messe 2015, are designed specifically to enhance the productivity and energy efficiency in a broad spectrum of sectors and applications in the Europe, Middle East and Africa (EMEA) region and in India (2015 Partner Country). Visitors will experience live demos of Delta’s new SCARA DRS40L Series solution, a robot arm system that is capable of improving daily productivity by up to 3 times in certain industrial processes and can be integrated with our in-house machine vision system for smart identification, inspection tasks and more.

The 2015 edition of Hannover Messe provides Delta with the opportunity to demonstrate its capabilities in expanding the degree of innovation, integration and adaptability of its industrial automation portfolio. These are:

- The newly-launched PAC Motion Control Solution includes Delta’s PAC MH-1 Series controller which differentiates from peers by offering greater programming flexibility with ready-to-use specific APIs such as CNC and robot control for dramatic simplification of the implementation process. High-performance multi-axis control processes such as lineal, arc, helical and high-speed continuous interpolations are supported by the excellent synchronization and precise control offered by the built-in EtherCAT and Delta’s own DMCNET communication interfaces. Thus, this solution is ideal for complex industrial processes where PLC-based technology shows limited reach such as thermal cutting, glass cutting, woodworking and stone milling.

- The SCARA Robot Solution integrates the new SCARA DRS40L Series with the robot controller ASDA-MS Series. The former offers an arm length of 400mm, a load of 3Kg and sensor-less compliance while the latter boasts built-in servo drive technology. This unique simplified architecture enables motion control of up to 10 axes (4-axis robot + 6 external axes) which translates into daily productivity improvement by up to 3 times in certain industrial processes. Smart identification and inspection functionalities can be added through further integration of Delta’s DMS machine vision system. Delta’s SCARA solution is suitable for industrial processes in the electronics, materials (rubber, plastics, metal), logistics sectors that require high-speed and high-precision such as assembly, coating, transporting and packaging.

- The Distributed Motion Control System features Delta’s newly-launched human-machine interface HMC Series which boasts built-in PLC functionalities and is capable of supporting motion control of up to 12 axes by supporting our very own DMCNET high-speed motion control system. The intelligent 3-axis servo drive ASDA-M Series acts as a “smart slave” and enables synchronous interpolation for ultimate control accuracy. Therefore, this platform brings high standards in terms of precise positioning and speed for 3-axis and 5-axis Cartesian robots and also for coil winding machines and gantry control platforms.

- With our Factory Energy Management Solution, Delta echoes the lead theme of Hannover Messe 2015, “Integrated Industry – Join The Network”, by integrating our in-house industrial visualization SCADA System DIAView, industrial Ethernet switches, mid-range PLCs AH-500 Series, vector control drives CP2000 Series and power/temperature meters into entire manufacturing facilities. This architecture enables comprehensive visualization of the manufacturing process, energy consumption, power quality and electricity cost analysis with intuitive and user-friendly interfaces. With its remote monitoring capabilities, this system supports decision-making processes for productivity and energy efficiency enhancements.

- Injection Molding Machinery Solution: The Hybrid Energy-saving System (HES) is a living proof of how Delta integrates solutions for enhanced productivity and energy savings. By leveraging Delta’s HES, molding machinery consume 40% less energy than variable displacement pump hydraulic systems. Automation devices such as HMIs, PLCs, temperature controllers and AC motor drives enable precise machinery speed control in order to reduce oil temperature by 5 to 10°C. This effect reduces 50% to 60% of oil usage and helps extend the lifetime of the hydraulic components.

- Solutions for the Food & Beverage Industry integrate Delta’s DMC machine vision control system for rapid detection or package defects and package content/direction confirmation for example. Delta’s mid-range PLC AH-500 Series offers high-extension system architecture to large-scale beverage production lines (maximum 100m by cable or 2Km by optical fiber).

- Energy Regeneration Solutions include one energy-saving solution for cranes and one for elevators. The former offers up to 30% energy savings in industrial crane operations by integrating the heavy-duty control drive CH2000 Series with the power regenerative unit REG2000 Series. The latter reduces >50% energy consumption in either cargo or passenger elevators by

- integrating the REG2000 with Delta’s Integrated Elevator Drive IED Series.

Image: new SCARA