Hexagon introduces Elements to help engineers design increasingly complex products with system-level modelling

Hexagon’s Manufacturing Intelligence division has today introduced Elements, new simulation software that helps engineering teams understand the behaviour of systems that are becoming increasingly complex in modern products. Using the software, teams can evaluate the performance and feasibility of new design concepts quickly to inform more efficient product development and reduce risk and cost.

Elements' system-level modelling can be used across a wide range of industries, from robotics to aerospace, and from automotive to energy generation.

Elements addresses the growing importance of integrated, multi-disciplinary system development and end-to- end workflows. Customers in every industry are demanding technologies that consider many physics domains and tackle mechatronics challenges in a robust way, fuelling a growing trend towards system-level engineering. Achieving this requires the integration of all relevant engineering disciplines, control systems, and third-party supplier systems to understand how the domains interact, and how a design decision in one discipline impacts others.

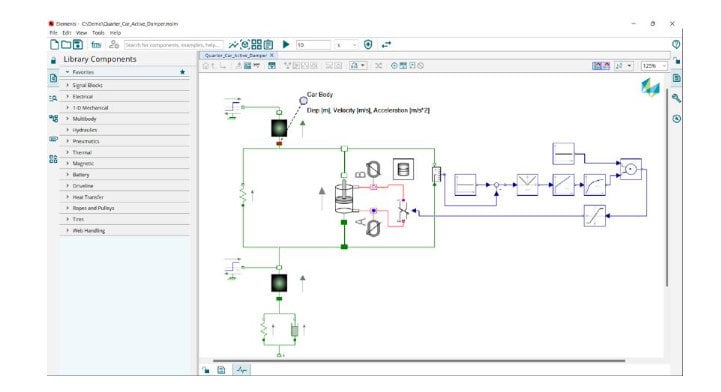

Systems engineers can easily learn to use the Elements software, using its drag-and-drop environment to model any physics type or logic and analyse systems by intuitively connecting blocks – regardless of whether they represent electrical, hydraulic, mechanical components – to solve system-level engineering problems. It is based on the Modelica language, which is an open and widely used standard for building fast, flexible, and customisable models.

Systems modelling is indispensable in the early design phases because little information is required – often a CAD model, equation, or lookup table is sufficient and a 3D mesh is not required. Elements further speeds up engineering development because it also ensures that system-level models compute quickly and efficiently by optimising equations and code for fast calculation, but with no loss of fidelity.

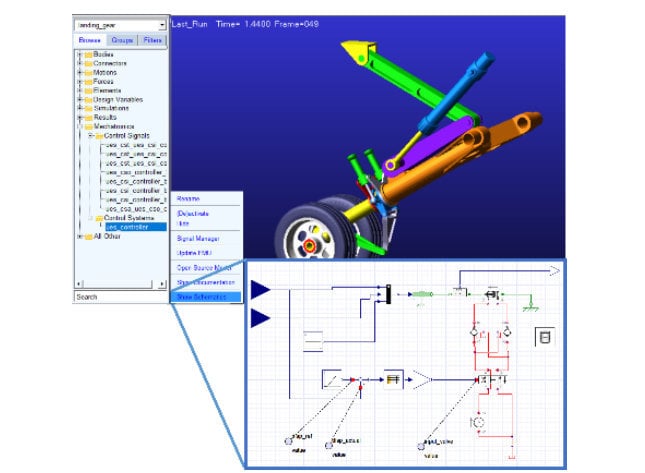

Landing gear simulation in Elements uses Hexagon’s unique SmartFMU capability to provide enhanced integration with its Adams software.

As the design develops, and components and subsystems are detailed in specialist simulation software, the components can be routinely integrated into a larger system through full compliance with the FMI standard and Hexagon’s proprietary SmartFMU technology. SmartFMU unlocks the Functional Mock-up Unit (FMU) for supported Hexagon products so that changes can be made directly in the Elements system-level model without having to go back to the specialist Computer Aided Engineering (CAE) software and its expert user. This helps to avoid resource bottlenecks, time-consuming switching between applications, and versioning problems.

Hexagon’s roadmap will see its best-in-class CAE technologies readied for easy and productive use with Elements. At launch, the software provides SmartFMU connectivity with Adams multibody dynamics software and Easy5. Future plans are likely to include workflows with Cradle CFD thermal-fluid dynamics and Actran acoustic simulation products, among others.

Both standard FMI support and the novel SmartFMU plug-and-play capabilities offer immediate value and address challenges of system complexity, including those for transportation electrification; for example:

- Helping automotive engineers to find optimal solutions to vehicle range optimization issues by considering a vehicle’s energy use under different driving conditions, taking into account eDrive design, regenerative braking, climate control, ADAS safety requirements, and battery choice.

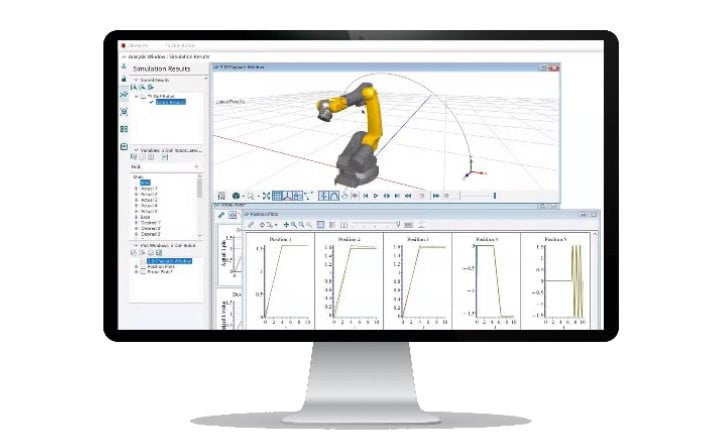

- Improving the flexibility and accuracy of industrial robotics by designing control systems that take detailed mechanical system vibrations and interactions from multi-body dynamics simulation into account.

- Right-sizing heavy battery systems in new eVTOL aircraft designs by helping engineers understand the power draw during take-off and landing, safety margins, and thermal management system controls.

- Implementing safer, more sustainable long-life battery systems by using Elements to design control systems that balance the improved performance of lithium-ion batteries at elevated temperatures with the impact heating has on cell degradation.

Elements combines user-friendly drag-and-drop modelling with comprehensive multi-physics simulation – e.g. mechanical, hydraulic, control, and many others.

Elements was developed in close cooperation with Maplesoft, building upon its powerful maths engine to optimise system equations and deliver fast efficient simulation to Hexagon’s customers. Chris Harduwar, VP of Strategic Solutions at Maplesoft, commented: “We are excited to begin this long-term collaboration with Hexagon, which has an impressive vision and track record of innovation. By combining the tried-and-tested Maplesoft system-level modelling technology with the extensive Hexagon CAE portfolio, engineers in many industries benefit from new productivity-boosting solutions that significantly reduce simulation effort.”

“Elements offers engineers an easy way to explore behaviour of systems quickly and find better solutions to problems using simulation, before committing designs to subsequent resource-intensive engineering processes. We look forward to a long-term collaboration with Maplesoft, using its powerful and open technology foundations to realise synergies with our extensive Hexagon CAE ecosystem portfolio and deliver valuable capabilities to our customers,” Mahesh Kailasam, General Manager for Design and Engineering Software at Hexagon, commented.

To learn more about Elements, please visit hexagon.com/products/elements.

www.hexagon.com