www.industryemea.com

08

'22

Written on Modified on

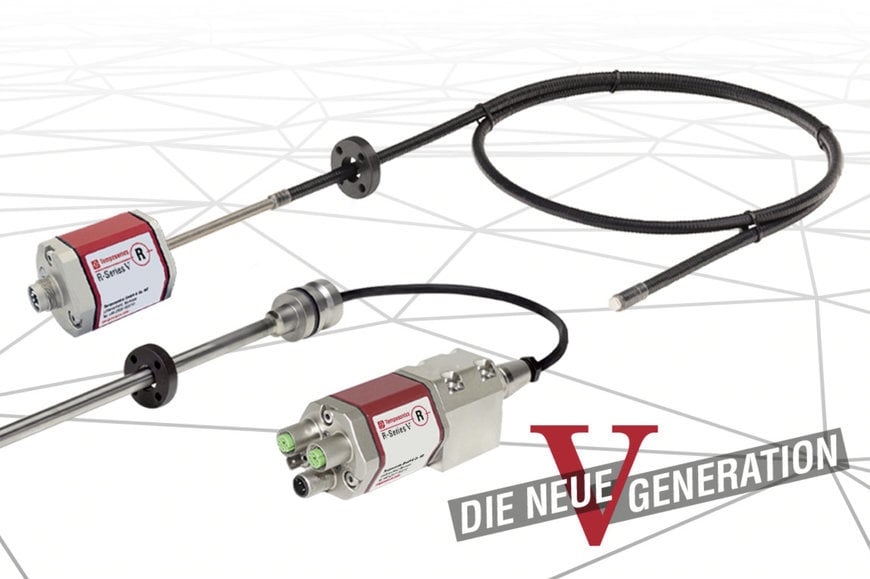

TEMPOSONICS ANNOUNCES THE NEWEST EXPANSIONS OF THE TEMPOSONICS® R-SERIES V POSITION SENSORS

The advanced sensor generation is clearly focused in industry 4.0 functions like machine monitoring, predictive maintenance and process optimization. The launch of two additional designs provides greater flexibility of use in industrial applications.

After the successful establishment of the youngest and most advanced sensor generation with profile- (RP5) and rod-design (RH5), the R-Series V is extended by two new designs. The powerful, magnetostrictive position sensor is now available with detached sensor electronics (RDV) and flexible sensor rod (RFV).

The R-series V RDV displacement transducer is ideal for mounting within limited space. In hydraulics section, the sensor rod can be installed in the cylinder, while the sensor electronics housing is mounted externally. The separation of the sensor rod and the sensor electronics housing guarantees a higher protection from process impacts.

The RFV is available with a stroke length up to 20 meters because of its design. The flexible sensor rod has the advantage of measuring straight and curved sections. In addition, the sensor can be rolled up compactly for transport and storage

RDV and RFV are available with the following outputs: Analog, EtherCAT®, POWERLINK, PROFINET, EtherNet/IP™ and SSI. They enable a multiposition measurement up to 30 positions simultaneously. The sensors of the new generation are fully backward compatible because of their proven electrical and mechanical connections and designs. Thus, the step towards industry 4.0 is easily possible by simply replacing the sensor electronics.

All R-series V sensors are supported by the optionally obtainable smart assistants TempoLink® and TempoGate®. They deliver detailed information about the application state, for example sensor status, temperature of the electronics, total operating hours, distance traveled by magnets and much more.

With the increased performance, ideal design and additional status information of the R-Series V, it is possible to optimize the performance of the application and the efficiency work processes. Better monitoring of the system reduces operating costs and minimizes downtime. In addition to the afore mentioned benefits a team of experts with extensive application knowledge supports the user from project planning to go-live of the machine in order to find the best sensor solution.