www.industryemea.com

03

'23

Written on Modified on

NEW DÜRR ORC MODULE CONVERTS LOW-TEMPERATURE WASTE HEAT INTO GREEN ELECTRICITY

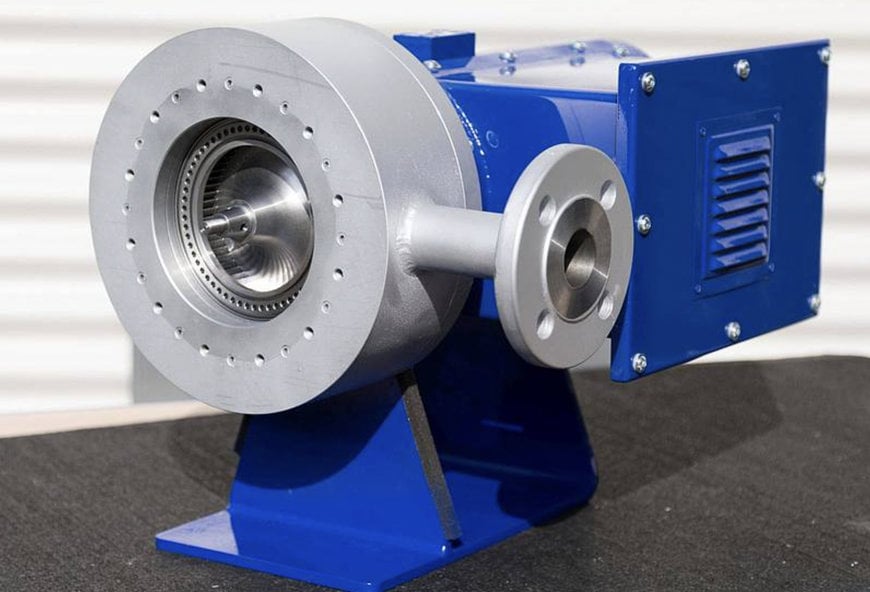

The Cyplan® ORC 70 NT is a new ORC module developed by Dürr that converts waste heat into clean electricity in the low-temperature range from temperatures of just 85°C.

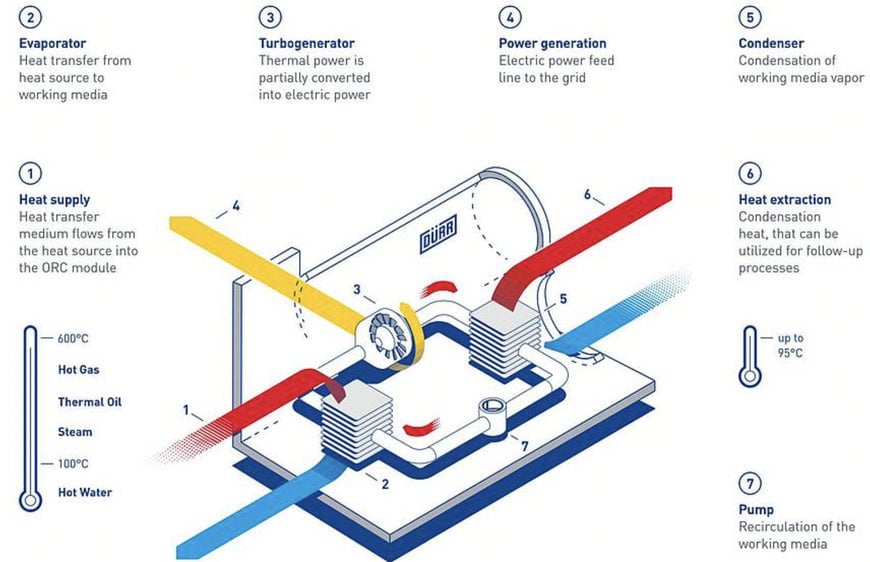

The Organic Rankine Cycle (ORC), a technology that converts thermal energy into clean electricity and useful heat, can make almost every industrial production process above a certain thermal energy threshold more environmentally friendly. The new Cyplan® ORC 70 NT now enables this in the lower-temperature segment, which is typical for hot-water networks, geothermal heat sources, and many industrial processes. The low-temperature system has a maximum possible gross output of 70 kWe.

Economical above 85°C

Previously, there was a direct correlation between electrical output and thermal energy’s heat and electrical efficiency. That is why until now, surplus low-temperature waste heat was released unused into the environment in most cases. However, with the new low-temperature module, clean electricity generation is attractive and economical from temperatures of just 85°C.

The Cyplan® ORC 70 NT works on the proven ORC circuit principle and joins Dürr’s comprehensive portfolio of ORC solutions, covering a wide range from 85°C to 500°C. Dürr modified the system control to implement projects as quickly as possible with tried-and-tested standard components. The Cyplan® ORC 70 NT is a plug-and-play solution for quick and easy integration into customer-specific systems. Unlike other products on the market, the new module can convert waste heat into clean electricity even at high outside temperatures, just like all Dürr ORC systems.

Better carbon footprint and process management

The first Cyplan® ORC 70 NT has been in operation since the renovation of a decentralized energy production system at an agricultural machinery manufacturer. Since then, two ORC systems coupled with a combined heat and power unit have been converting the waste heat produced into a maximum yield of clean electricity in the most economical way possible. Not only does this lower the company’s energy costs, but it improves its carbon footprint and ensures stable process management. The low-temperature ORC can utilize heat peaks in the heating system so that the combined heat and power unit can operate around the clock at its highest efficiency for the first time.

www.durr.com