www.industryemea.com

05

'23

Written on Modified on

New Pilz function block for dynamic muting on press brakes

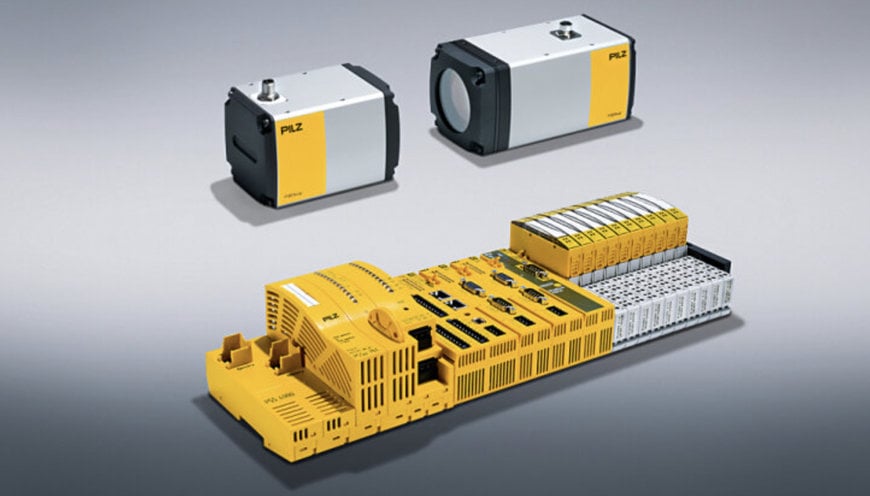

For the camera-based protection system PSENvip 2, for safeguarding press brakes, Pilz now offers a new, certified function block for dynamic muting.

As a complete solution with the Fast Analysis Unit (FAU) in the automation system PSS 4000, the camera-based protection system PSENvip 2 offers maximum safety for press brakes in accordance with EN ISO 12622 and is suitable for both new machinery and retrofits.

Automate muting, save time

The new function block for dynamic muting is available via the automation system PSS 4000. In conjunction with the FAU module, it is possible to configure tool class, muting end point or protected field modes simply and quickly, for example.

Safety functions such as position, speed, braking ramp, overrun distances and protected field can be monitored. The new function block ensures that dynamic muting is initiated once the check is complete. As the effort involved in manual programming is no longer required, the press application is commissioned quickly and safely. That saves time and avoids subsequent costs.

More power for the press

With PSENvip 2, foreign bodies in the optical protected field are detected immediately and the press operation is stopped safely – without compromising productivity. That’s because the solution allows operating speeds to be perfectly adapted, thus enabling higher cycle counts: due to the dynamic muting process, the speed of the upper tool can be continuously adapted via dynamic adaptation of the protected field. Only from the detection zone onwards is this reduced to the lowest level. In conjunction with user-friendly diagnostics, the safe, complete press-braking solution increases the availability and cost effectiveness of press applications in forming technology.

System for efficient bending processes

The complete solution comprising PSENvip 2 and the Fast Analysis Unit in the automation system PSS 4000 from Pilz guarantees faster processing, and consequently an even faster shutdown of bending processes. In the automation system PSS 4000, the PLC controllers PSSuniversal PLC are used for this purpose: PSSuniversal PLC monitors all the safety-related functions and can also perform the press’s standard control functions. As a result, the solution package from Pilz achieves maximum productivity while being simple to handle, and ensures an efficient bending process.

www.pilz.com